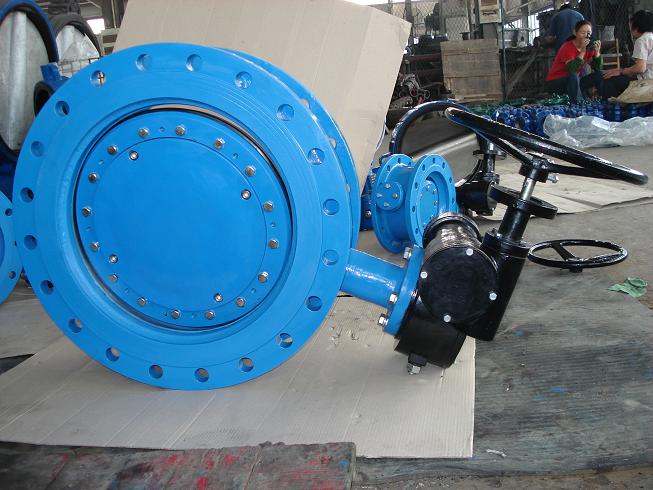

Double flanged eccentric butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Double flanged Double Eccentric Butterfly Valve

PN10/16/25

DN100 ~ DN2000

Technical Specifications

- Design and manufacture: EN593, EN1074-1 and 2

- Face to face dimension: EN558-1 Series 14 (DIN3202 F4)

EN558-1 Series 13 (BS5163)

- Flange dimensions and drillling: EN1092-2 PN10/16/25

- Size range: DN100 - DN2000

- Max. working pressure: 1.0/1.6/2.5 MPa

- Inspection test: EN12266

- Working temperature: -15°C to +80°C

- Suitable medium: water

Main Fetures

- Double eccentric disc reduces seal wear and torque

- Body seat ring is welded directly on the body

- Bi-directional flow and low head loss

- Disc sealing ring to be replaceable on pipeline without dismantling the valve

- Body and disc inside and outside epoxy powder coated (min. 250 microns)

- Opening and closing indicators are provided

- Coupling flange for electric actuator in compliance with ISO5211

- Gearbox and electric actuator operation available

Main Parts and Materials

Body and disc: ductile iron EN GJS500-7/400-15

Shafts: stainless steel AISI 420

Body seat ring: stainless steel AISI 304

Disc sealing ring: EPDM or NBR

Retaining ring: stainless steel or ductile iron

Shaft bearing: Du bushes (self lubricating bushes)

- Q: I have a curtis toledo compressor at my house. While moving it a helper dropped it on its side into the tank and broke off these 2 valves off the very top of the compressor. They had a copper line that ran off both of them and went over to the auto on/off switch, I'm guessing that's what it is. Where can I buy these or at least what are they called?

- The valves are probably one way check valves and the line is called the discharge line. The valves could also be un-loader valves that release the head pressure when the compressor shuts off. For parts just google your compressor brand and model for parts dealers.

- Q: I have a Burnt Valve in my Ford 302 EFI Crown Victoria. I know that i will have to have machine work done to the head but im not even gonna mess around im going to just pull both my heads off since theres alot to remove to even get to the heads i Just need a list of parts that i'm gonna have to buy for this project

- You will need a head rebuild kit: valves, valve seats, valve guides and all the seals and gaskets. You will need a valley pan gasket. Leave it to the machine shop to get all the parts that go in the head. I left out valve springs and spacers that may be worn out of spec. If you ever pulled and replaced heads, you have a good idea what you're in for. If this is your first time, get help from someone with experience so you don't end up with a basket case needing to be towed to a shop for assembly. That's a nice engine and you shouldn't try to play cheap fixing it.

- Q: Anyone know where the pcv valve is located on a 2000 Lincoln Ls V6 3.0

- find the valve covers and it's on one of them, it plugs into the valve cover and has a hose running to it, take it out and shake it and you should hear a ball bearing rattling noise if it's good.

- Q: I wanna do it myself My dad knows how But i must buy the parts I have a rmz250 and i was wondering if u can jus buy valves and seals and jus put them in without grinding since the seals are new i heard u must gring the seals to get the valves to sit flush againt the metal serface but cant u jus buy new seals and retainers and put that in plus the valves and ur done?

- you *can* just put the valves seals in and run it but it is NOT recommended. If you want the best seal which will = the most power, the valve seats need to be cut. If your not running a titanium intake you could get away with just lapping the valves with course and then fine lapping compound. I know a lot of people who just lap them in, but the most professional way with the best results is to cut the seats.

- Q: I recently adjusted the valves and put new valve covers on my bug and now I have a leak around the fron corner of one of my valve covers. What happened? What can I do?

- For clip on valve covers it best to add some tension to the wire bails. You can do this by slightly bending the centers inwards. Also a light coat of Permatex ultra gray on both sides of the valve cover gasket works great. When you replace the valve cover gasket, the services it rides on on must be very clean. So pop off your covers and perform the steps above and you should be fine. Here is a link to a video we made on valve covers.

- Q: Hi, I am a junior in high school and I play the trumpet. For the past week or so my 1st valve has been odd. It gets stuck badly when it hits all the way to the bottom, and I can't seem to get it to stop. Normally when valves are sticky I just use some valve oil and it helps a lot. But it doesn't seem to work this time. It is a Bach if that helps. I think there are other types of valves so I'll say that there is a spring inside from like the middle to top. If you could help me out that would be great! Thanks =)

- No, it's ok, they are both the same. I've been using trumpet oil on my trombone slide for the past 4 yrs. It is less expensive, ad usually in stock. It's not bad. If i've used it for 4 yrs. I'm sure you can use it too! my BFF even used to use my trombone oil, that's how i ran out in the first place. I hope you do well with your instrument! Both are made of the same oil products. But i don't reccomend using cooking oil, or vegtable oil, it is too thick and makes the slide/valves greasy and is very hard to get off. Hope this helps.

- Q: I have a suzuki bandit 1200 (2001) and I think it needs a valve adjustment. The engine is tapping at idle and while riding but I cant stop riding long enough to get it fixed. All the shops I checked with are booked for a week. Will I make the engine worst by riding it like this?

- Motorcycle Valves

- Q: Okay I know lots of people wonder what is better presta or schrader...well I realy don't. My bike was made for presta and thats what I have a question about. So I just got my bike back after is being stored away for a few years, so yeah it was neglected. Question is now that I am doing a tuneup on it I found out the valve came out of the tube. I don't know if that is normal and if I am able to put it back in. It looks like there made for the valve not to come out but I just want to make sure before I go out and buy a new tube. Hope you can help. Thanks. -Sarge

- Just replace the tube. The rubber ages and goes bad after a year or two whether you ride the bike or not.

- Q: 1998 camaro3.8L v6sometimes when i start the car, it makes this loud ticking noise that goes with the RPMIm pretty sure its the valve, anyone know how to fix it, and how much it might cost?

- HI what you are hearing is not a valve but a lifter... MAYBE... Here's a couple of things that well make it tick. 1) an exhaust manifold gasket leak well sound like a ticking lifter. ( if the noise goes away after the car warms up it might be this gasket.) 2) a bent push rod well make a lifter tick ( as the tolerances would be off) 3) a bad lifter well make a ticking sound. If it is indeed a lifter then best leave it to a pro.. As the intake would have to come off to replace ALL the lifters (you can't buy just one). If its a push rod just the valve covers well have to come off.. to isolate the sound you can use a long piece of hose 3 ft. or so. hold one end to your ear and move the other around the motor compartment and see if you can tell if the sound is coming from inside the motor (lifter), inside the valve cover (push rod) or outside the motor exhaust gasket. good luck tim

- Q: I wanted to clean my 2005 accord ex 2.4 idle valve. I'm not sure where it's at any pictures or websites ? And will cleaning it make any difference

- Probably won't help. Idle Air Control valves are blamed probably ten times as often as they are at fault in Honda engines. It is mounted on the side of the throttle body and has a connector with wires instead of hoses. You don't mention why you are interested in the IAC valve, but if it is because of idle hunting (revving between about 500 rpm and 1500 rpm smoothly and rhythmically), a bubble in the coolant is by far the most common cause. If the coolant is changed and not bled the normal idle speed can't get hot coolant to the Fast Idle Thermo valve (FITV) so it figures the engine is cold and the valve opens to raise the idle. That raises the coolant to the FITV, which then decides the engine is warm so the valve closes, dropping the idle speed, over and over. Burping the coolant, by opening the bleed nipple on top of one of the radiator hose housings at the engine half a turn until a steady stream of coolant comes out, should stop that. Do it with the engine cold.

Send your message to us

Double flanged eccentric butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords