API Cast Steel Check Valve 700 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

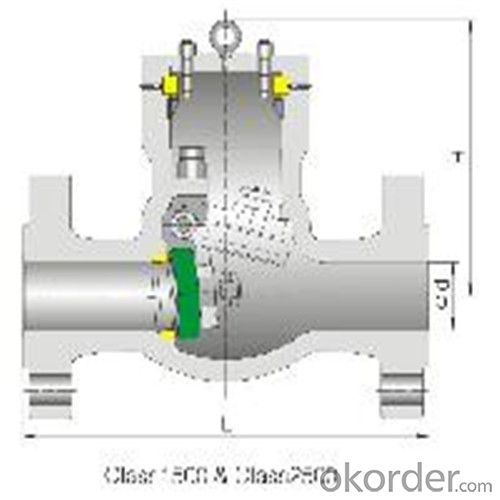

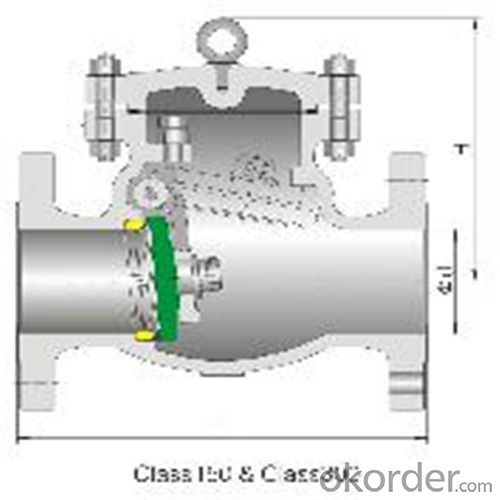

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check="" valves="" and="" welded="" on="" seat="" can="" be="" also="" optional="" if="" being="" requested="" by="" the="" customer.welded="" is="" used="" for="" nps="">12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I have a 1997 Toyota Corolla. My check engine light has been on. I tried to get my car smogged and it failed. I then got an oil/air filter change and just yesterday I replaced the EGR valve which was the result given after 2 diagnostic tests. The mechanic gave me my car and the check engine light was off, I've only driven about 5miles and the light is back on. I have to pass smog asap to register my vehicle. I plan on calling the mechanic back and telling him the light is on, but could it just be a sensor?

- it could be a sensor ! the EGR code probably showed up because a sensor was interfering with the valve !

- Q: How do you clean an EGR valve on a 1999 Ford Taurus DOHC? What do I do and what can I use? Will water work? I've read a lot about a plunger mechanism but I have no idea what this is. Please explain in the best detail you can how to remove, clean, and re install the EGR valve?

- The egr valve doesnt get dirty on its own; if there is a problem with foreign material in it, its coming from the exhaust stream, not the valve. But if you need to clean it anyway, then just unbolt it, push in the valves plunger from the bottom, and pick out anything blocking the valve from closing. They do not plug up. Also, check to make sure the vapor holes where the valve bolts on are clean, they do plug up. the mechanics of it are pretty basic.

- Q: I've been playing french horn in school for about five years, and I'm not exceptional by any means! But I love the instrument. Our school district bought a french horn a few years ago when we didn't have enough french horns for players. The almost new Holton has great tone. But unfortunately it fell into ignorant hands and has been neglected for two years. I just received the instrument and cleaned it up and got it back up to snuff, except for the valves. I can't get them to run smoothly!! They act all gummed up. I've put oil in the top and bottom of the valve, and I've dropped a couple drops in the tubes down onto the valves, but they're still gummed up! Do I need to use more oil?? Or what? Any suggestions?

- Sounds like your oiling correctly but you need to get the dried oil out, that's the gum your feeling. One way is to have the school send it to the repair shop, its not your horn so don't spend any money on it. Another way is to flush them out with a thin valve oil. Where can you buy a quart of valve oil? Walmart and Kmart has it but not labeled as valve oil. Look for Lantern oil , the stuff used in oil lamps, it is very cheap and many of the valve oils are made of the same stuff. Take out all the crooks on the instrument and flood the valve with the lamp oil, this should flush out the gum. After you have dumped the lamp oil re-oil the way you have been. (Lamp oil is not dangerous, it burns if you hold a match to it but that is about it, you can also use charcoal lighter)

- Q: I have a Jupiter double horn. The thumb valve will randomly stick down and not want to come back up. It however only does this when I play a scale or am in the middle of a song, so when I ask the director or an instrument repair person to help, they think I'm crazy and see nothing wrong with it. Also, the first valve is slightly bent sideways towards the second valve. I got it used and it came like this. It is not horrible, but that makes it significantly slower than the other valves and sticks a LOT. All repair shops do is take my money and claim they've fixed it when they have done nothing. It is so frustrating. What should I do? And the oil doesn't help with either of these things, which is even MORE frustrating.

- Open up the #4 valve cap and flood the top with valve oil, put the cap back on and turn the instrument over. Put valve oil in the crack where the valve comes out of the bottom of the valve case. This can be hard to see. Put some drops on every moving part of the valve action. I can remember the layout of that valve but I don't think you can shoot oil into the valve. Try all that I said above and see if that helps. Rotate and wiggle the valve between each step.

- Q: okay, where the dome is on the head (where the flat part of the valves sit) the intake is uneven and the air+gas mixture escapes threw the open space when the piston goes up into the compression stage, and ignites shooting flames out of my exhaust port. the space is small but u can see light threw it when the valve sits there. Would some kind of Liquid metal work? or gas+heat resistant epoxy work to take the place of the missing space? I would file it but that would not be precise and time consuming, and i would buy a new head for $150, but the dealer doubles that price! and no way am i paying $300 for a new head. any comments would be well appreciated!

- take bike to dealer and get it fixed right.

- Q: What is the purpose of the LNG Vs Propane Valve that has to be installed on Gas Stoves/Ovens before use ? How can I set it myself for Propane ? What negligible effects would I experience if I hook a stove up to Propane while the valve is set-up for LNG ?Thank You !

- LP gas and natural gas work off of two different pressures. Usually there will be a inner spring that need to be changed out inside the valve, and the orifice will need to be changed as well. If you don't convert your valve, it can prove to be very dangerous! Most likely it will only have an erratic flame, and burn very dirty. The flame will burn out of control and have orange color to it. However, it could result in not burning off all of the gases as they are released, and could cause an explosion. Most of the time in the owners manual it will have step by step instructions on converting LP to Nat, or vise versa. Remember, gas is a safe alternative to electricity, but if not handled correctly it can be very dangerous. Please proceed with care, or if you are uncertain with yourself, call a qualified technician. It shouldn't take em more than an hour, and most techs charge around 60 bucks an hour. A cheap price for a job done safely.

- Q: Hey guys Itook my car to mechanic because my engine light was on and the code showd that it was unsufficient egr lift or something like that....they had changed the egr valve before so this time they said there was carbon build up and they cleaned it and my car runs great now. i don't have problem with accelaration and the engine doesn't stall when i stop, BUT the light came on again and still shows the same code. I am sick of it!!! anybody knows what else could it be? It's 94 honda accord with 140 000 miles on it.

- The hose may puncture some where,their could lose tappet cover you could have blown inlet gasket.Regards Martin.

- Q: I have a 1987 Chevy Blazer with a 5.7 liter 350 engine. Where is the PCV valve located on it?

- PCV has been in one of the valve covers for Many years.

- Q: 1990 Pontiac Sunbird, I took a piece of hose going to the egr valve to try and see if it is working properly, but with car off, I can suck through, and blow out into hose going to egr valve, and it doesn't seem like there's any seal stopping air flow either way...is it supposed to, or what is this supposed to do?

- What is it that you are trying to do? Your question is sort of vague.

- Q: Why would oil be leaking from a blow off valve?i own a 05' gti 1.8t, i have had the blow off valve for about a year now, its a HKS SSQV, but i just revently noticed that when it blows off, there is a spray of oil that comes out..... why would it be leaking oil through the blow off valve? i know VW dont really go well with blow off valves, but it hasnt given me any problems until recently....

- vw has a pcv system it recirculates the crankcase air into the intake, your car if fairly new, but this is most likely the problem. at least its the most simple to check / fix. i dought the turbo is gone if its the stock ko3s, they can take a beating. the pcv valve is the black saucer shaped peice (kinda looks like the stock diverter valve) , its in the TIP by your N75 valve. these get filled with oil and start to dump in into the intake. did you switch the set up to run the BOV on the cold side? like off the throtal body hose? if so, this could STILL be the problem. if you take off your lower inercooler pipe and look inside for oil build up. and pull the n75 valve out and check it for oil. id think aboout replacing the pcv valve with a catch can. your real problem is yet to be noticed if your dumping the air out and not recirculating it into the intake, the car WILL RUN RICH, as it reads the air it adds fuel, but with a BOV your loosing some air BUT keeping the fuel. so id expect to see some bad cats and o2 sensors good luck

Send your message to us

API Cast Steel Check Valve 700 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords