API Cast Steel Check Valve 300 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

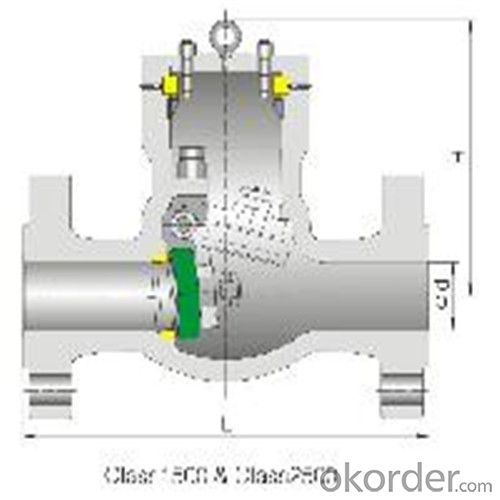

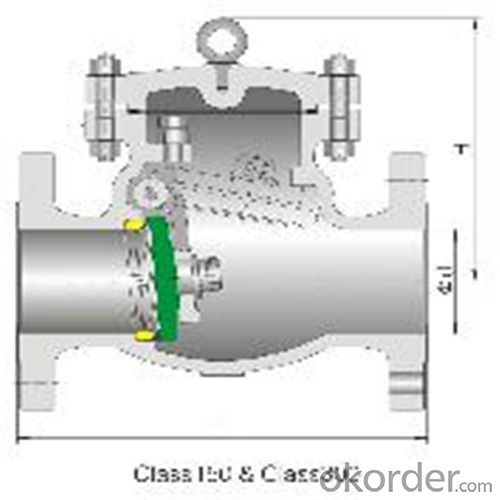

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: i would like to hear from anyone who has actually had the work done. i also would like to know if the valve worked.

- I have never heard of a backwater valve. What kind of car is this? We need Year, Make and Model Can you be more specific.

- Q: My AC leaks and mechanic says it is shrader valve. Is it expensive?

- A Schrader valve is a simple push valve used to keep pressure inside a container or system, while making it easy to add more pressure when required. The valve stems on your car's tires are Schrader valves. The PARTS to replace a valve are fairly cheap, but labor and materials to repair an AC system may run the bill up.

- Q: Surly Pilots don't just switch the fuel selector valve of mid flight

- It is standard procedure if you are going to crash to reduce risk of fire. Also, with the type of fuel system the Piper Saratoga has, the engine will run for six minutes with the selector in the off position and cannot be selected to off accidentally.

- Q: The valve on my mountain bike tire has a leak, so I want to go buy a new valve (and maybe a couple spares)... how much is the average cost?Thanks!

- Pump the tire up to max and then release the air that may clear any dirt out. If it's leaking around the base it needs patched or replaced.

- Q: Is there a product that can fit over a foot valve to give it further protection in muddy water? I am looking for something for forest firefighting in mind. Something like a screen box something else that can give it further protection. It would be nice if it was small, and compact. Pictures would definitely be an asset. Thanks to everyone that answers. Greatly appreciated.

- most foot valves i have bought come with a strainer attached perhaps you should look for that type. if your valve has a strainer you may consider making a further coarse strainer out of a ball of chicken wire and place this over the foot valve assembly(thats what i do for the cold water supply to my house) don't compress the chicken wire very small as it will block up i tie the wire filter on with galvanized wire then i can easily replace it if necessary ps i tried stainless steel pot scourers but they were to fine and blocked easily

- Q: Why is the atrioventricular valve in the right ventricle called the tricupsid valve and the atrioventricular valve on the left ventricle called the bicupsid valve?

- Bicuspid has to flaps and the tricuspid has 3 flaps

- Q: I took my 2nd valve out to wash it (i couldn't find my oil, but it worked fine) and I've tried making the number face the mouthpiece, yet it still is messed up and won't let me play a lot of notes.

- see if there is a slight protrusion on the valve. probably on a piece of plastic near or above the spring of the valve? that should fit in a notch in the trumpet valve tube. Just insert your valve partly in until the protrusion is resting on a ledge-like part. Then turn your valve around the tube gently until you hear a click when the notch goes in. You are right, the number on the valve usually faces the side where the mouthpiece is. Make sure your other valves are also placed in there correctly. If all else fails, ask the person who's teaching or taught you to play trumpet. or go to a trumpet store. Enjoy practicing!

- Q: i know its going to drop some oil, im just wondering to what extent? how much oil is going to spill out?

- If the car gets to sit for several hours that should not be a problem. Otherwise give the other paint 72 hours to dry hard before removing the valve cover. You may have to rag it a bit. Use hi-heat paint on the covers.(follow directions on the can)

- Q: I'm a 68 year old male. i've had mitral valve regurgitation all my life . recently an echocardiogram listed it as 3 plus. I'm in otherwise good health and continue to jog 3 miles three times a week at about a 9 minute mile rate. Is surgery advised.

- Have you asked your Cardiologist this question as well as your Primary? I do not know what the reading indicates...sorry!

- Q: how long do people usually live after mitral valve repair?

- depends on luck and how you deal with life?

Send your message to us

API Cast Steel Check Valve 300 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords