Ball Valve For Heating SupplyDN 80 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

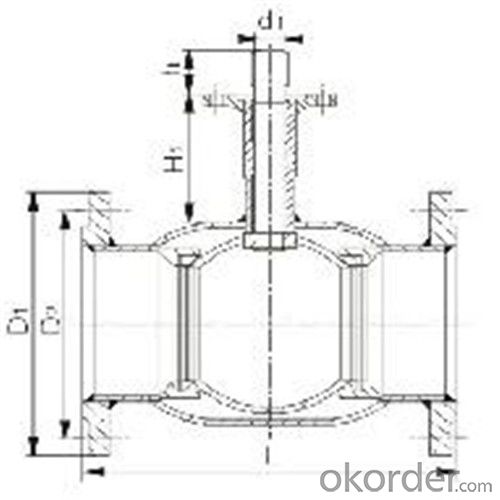

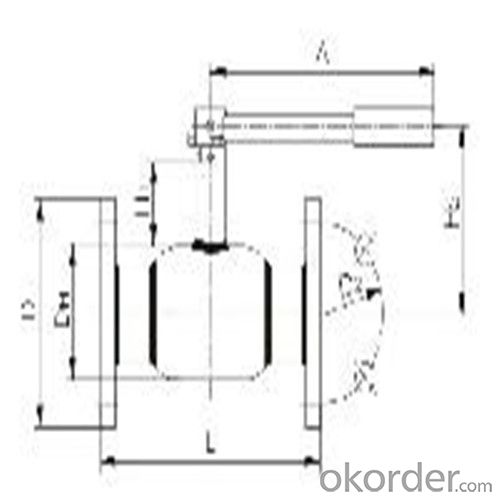

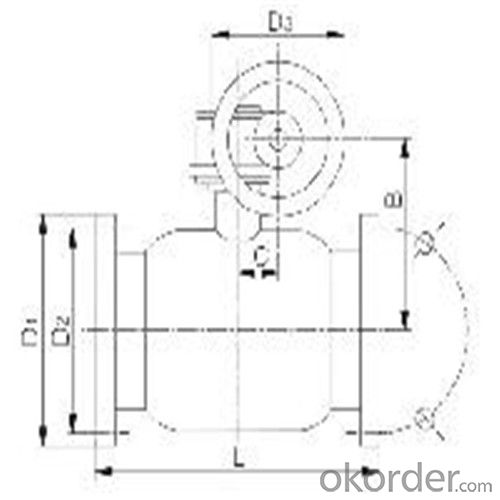

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

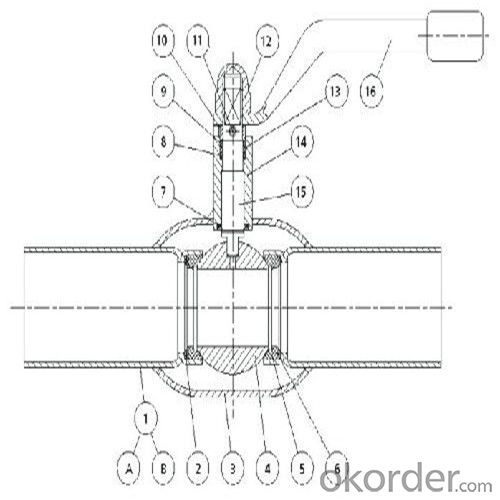

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Does a faulty pcv valve (Positive Crankcase Ventilation valve) cause excessive exhaust smoke ?

- Yes. This would definitely cause excess smoke, probably white in color. If the pcv valve is bad, it's probably leaking water into your oil, and oil into your cylinders, thus your engine is burning oil. This is an extremely cheap and easy fix. Make sure that when you change the pcv valve, you change the pvc valve grommet as well (the little black seal around the valve). Also, be extremely careful not to crack any plastic from the pcv valve or the grommet, because pieces of the plastic could fall into your intake manifold, and then you have to remove the intake manifold cover and that can become a pain in the a**.

- Q: Im looking for a new BBb tuba. i would like six valves at 4+2. but if not looking for 6 valve BBb tuba

- I don't know how long you've been playing tuba but 6 valve BBb tubas are virtually non-existent. No current brass instrument manufacturer will have that in their line-up. Tubas with 6 valves are already rare and are pretty much limited to F tubas. If you want a 6 valve BBb (I don't know why you even need/want that many valves) then your best option would be to buy a 5 valve BBb tuba and having it modified to include a 6th valve. Either way, expect to pay a minimum of $10000 (ten thousand) for the instrument.

- Q: We have an oil steam system. There are Dole valves - 1A on each of the radiators. We bought new ones. They don't seem to be working. They look like a bullet shape with a screw in (on the side of the bullet) to the radiator. On the top of the bullet is a slit with numbers 1-10 on a dial. A picture we saw on the web showed a plastic piece of tubing in the screw part which looks like it goes into the radiator. If we remove the valve, the radiator gets hot with steam coming out of the hole. With the new valve on, the radiator barely gets warm. We're in Piscataway, NJ 08854. H-E-L-P.

- First off these are vents , the valves are at the bottom of the radiator where the pipes come in. Sounds like the vents are either closed or broken. Try turning the adjustment screw if that doesn't work I recomend replacing the with vent from a company called ventrite the valve you are looking for is a vent rite #1. These are adjustable vents used to balance the heat throughout your unit the dial at the bottom is labeled 1-8 start with all of them on 8. Now when the radiators heat up if you find some are getting hotter faster turn those down a notch and check again in a day or so.

- Q: I live in Houston (where it hardly EVER freezes during the winter..) This winter it froze and the valve on the sprinkler system flew off and water started shooting straight up. Now that it's getting warmer and I'm going to need the sprinkler.. I have to repair it. Is this an easy fix that I can do myself? Or should I call someone.

- easy.. just dig around the valve a little bit.. unscrew the valve .. and screw new 1 in...removing the dirt is necessary so when the broken valve is removed dirt dont fall into the open pipe... it is probably only about 8 inches deep... and 7 dollars for a new valve

- Q: What are the requirements for valve automation?

- Some valves are controlled to maintain a fixed pressure on a system. Others control the level in a tank or vessel while still others actually control the flow rate in a pipe or line. The automatic control of flow through a valve requires a sensor to determine if flow is needed or what the flow rate is. You then need a controller to take this input and then adjust the valve to achieve the desired result. This is called a control loop. Some are all electric/electronic while others are all pneumatic. The valve itself is a specific valve designed to perform the function intended. It is not a good idea to take an existing on/off valve like a gate valve and try to control flow. These type of valves do not have a flow characteristic that is proportion to valve opening while a control valve does.

- Q: How do you repack an osy valve? Where do you get the packing from? Do you have to shut down the water to do it?

- where is i get the packing gland material

- Q: had a water heater put in after that i have low hot water pressure it get hot but goes to a low stream.when i try to adjust gate valve it keeps turning

- A gate valve is used as a shut-off, not a regulator. It is supposed to be either all on or all off, and the handle only has a total movement of 90 degrees. When the handle is aligned with the pipe, it's on, and when the handle is perpendicular to the pipe it's off. If the handle is turning more than that, it's broke and needs to be fixed or replaced.

- Q: I was getting something to burn and smoke up this empty 2 liter bottle for my friend's brother's science experiment. We didn't find any wood, so I took his trumpet valve oil, dripped some on a piece of wood that wouldn't burn and make it smoke up. Does burning valve oil have any negative side effects as opposed to say, regular oil? I shouldn't have been so lazy and just used vegetable oil or something haha....

- Valve oil is basically just mineral oil and various other ingredients. You can buy pure oil, and it's also the main ingredient in baby oil and other medicines. Nothing wrong with burning it.

- Q: What is the primary function of valve seals?

- Valve seals are placed over the intake valve guides so oil will not be drawn into the combustion chamber on intake stroke.

- Q: The water inlet valve on my Kenmore washer leaks. Is there an easy way to replace it? Last time it broke they charged me over $100 to fix it.

- YES okorder when you get there you will need your numerical model number that you will find by lifting the lid of the washer looking down and toward the back of the machine just under the lid where its hinged. Once you type in the model number do a word search by typing in valve. It will give you a numerical part number that you can call your local service company with and get a price. Or you can usually call any service dept local with your model and they can look it up for you and sell you the part. Good luck...

Send your message to us

Ball Valve For Heating SupplyDN 80 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords