Pneumatic Safety Valve with API 6A Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 200 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

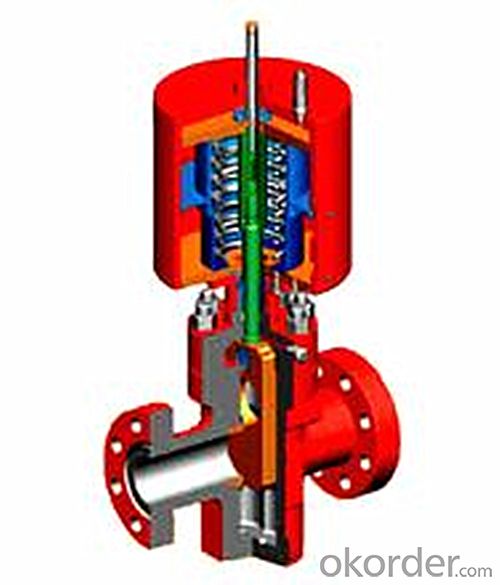

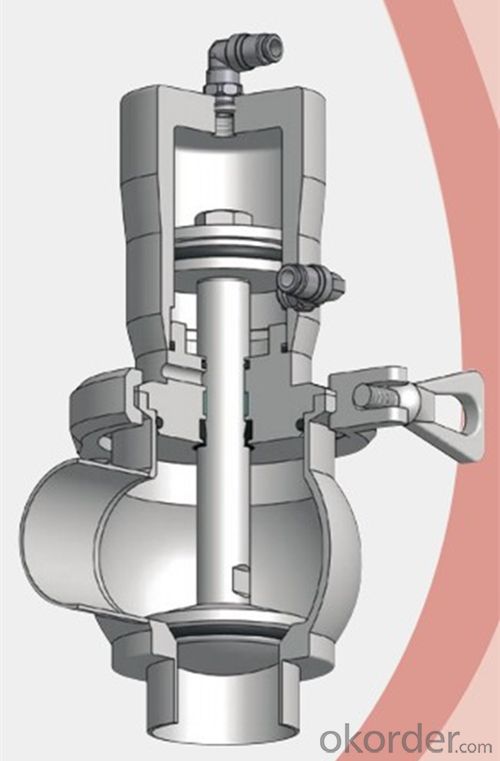

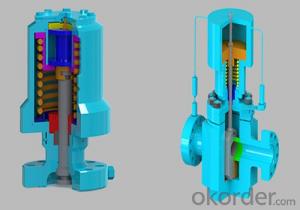

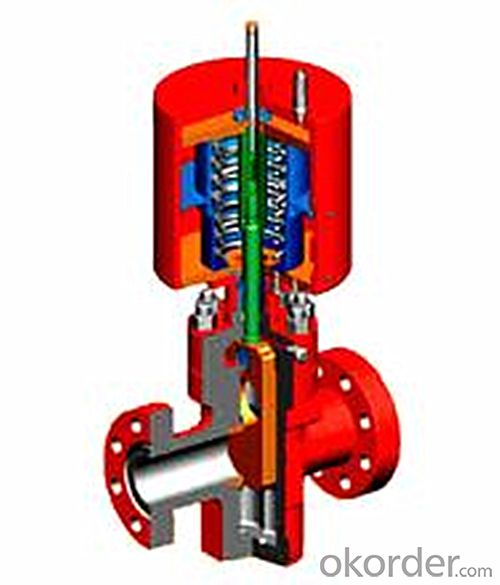

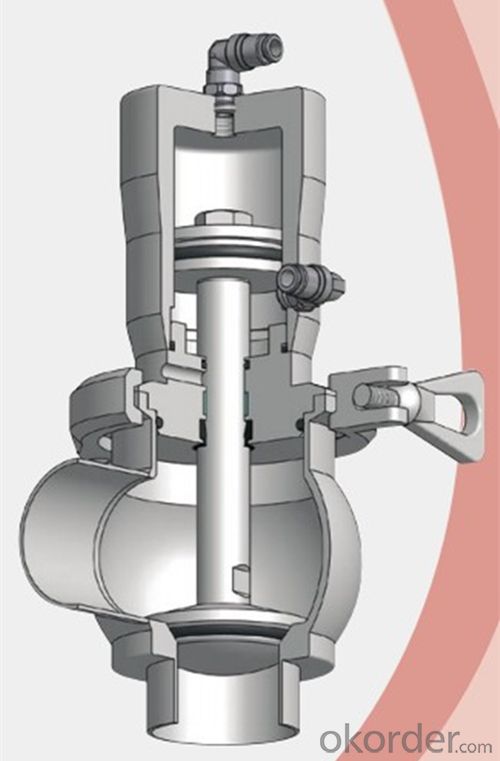

1. Structure of Pneumatic Safety Valve Description

The Pneumatic safety valve is mainly used on the wellhead X-mas tree of ocean, offshore platform or onshore, whose function is when fire hazard or abnormal high or low pressure happened, it can close the safety valves automatically according to set procedure to ensure the wellhead safety.

2. Main Features of Pneumatic Safety Valve

1) API Standard

2) High quality and fast delivery

3) Best price and service

3. Pneumatic Safety Valve Images

4. Pneumatic Safety Valve Specification

Nominal Diameter:2-1/16"~4-1/16"

Nominal Pressure: 2,000Psi~10,000Psi

Material class:AA~HH

PSL class:PSL1~4

PR class:PR 2

Medium:Petroleum oil, natural gas, water, mud

End connection:API standard connection

5. FAQ of Pneumatic Safety Valve

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in values products in China, can supply series of values to around the world.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put

an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I have a Jupiter double horn. The thumb valve will randomly stick down and not want to come back up. It however only does this when I play a scale or am in the middle of a song, so when I ask the director or an instrument repair person to help, they think I'm crazy and see nothing wrong with it. Also, the first valve is slightly bent sideways towards the second valve. I got it used and it came like this. It is not horrible, but that makes it significantly slower than the other valves and sticks a LOT. All repair shops do is take my money and claim they've fixed it when they have done nothing. It is so frustrating. What should I do? And the oil doesn't help with either of these things, which is even MORE frustrating.

- thats easily particularly straightforward for brand spanking new horns, somewhat hand-crafted ones. The valves are nevertheless very tight and there would be steel debris nevertheless interior the tubing/valves from manufacture, it in basic terms desires to be taken to a competent restoration save and wiped clean thoroughly. previously you do this in basic terms attempt putting oil on the lower back and desirable (decrease than valve cap) bearings, and take out each and all the valve slides and positioned some mild oil (Al Cass works constructive) oil into the valve itself. in the event that they nevertheless draw close then take it to be wiped clean. and FYI concert activities on incredibly new horns isn't a competent concept, apart from mechanical subject concerns, you're able to desire to take time to get used to the device and its pitch dispositions. in view that probably is unquestionably no longer your final horn, in basic terms evaluate that next time.

- Q: It's filling up a 5 gallon bucket roughly ever 9-10 hours. It was leaking with an old valve and has been replaced, and after being replaced it didn't stop. The temperature has not been adjusted higher or lower, it's exactly where it was for the year before the leak started. Any ideas?

- You might want to check the water pressure in your home. If it is too high, when the water is heated it expands and may exceed the pressure setting of the TP valve. You may need to lower the incoming pressure or install an expansion tank. Good Luck

- Q: i need to know the setting of the valve and a little advice on the up and down of the valves

- Intake and exhaust valves have different clearances.Which one?To check the clearance- the cam must be in the proper position.Then you take a feeler gauge and measure the distance-you have to do this to each valve before you can remove the cam to make an adjustment.Under the cam lobe-on top of the valve there is a can that rides up against the cam lobe.Between the inside of the can and the top of the valve there is a little round pocket that has a shim that looks like a watch battery.These shims come in different sizes--replacing them with a different size is how you make the adjustment.This is not anything that I would try to do without a manual--things can go bad real quick in the adjustment stage.Not a job for a 1'st timer but you can learn if you watch someone doing it.

- Q: compare the structure of the tricuspid valve with that of the pulmonary valve??please help me

- Pulmonary Valve Structure

- Q: where can i get my Idle air control valve cleaned on a 84 celica supra

- There should be a VECI map under your hood that shows you where this valve is located. In a pinch, find a Haynes manual or a Robert Bentley manual that has pictures in it. If you can find the valve, you can clean it yourself with a can of spray Gum-out. While you're at it, clean the throttle body and PCV valve, too. Hopefully, you have had the good sense to have used only genuine Toyota coolant in this car, since Toyota heads require a special coolant formulation to prevent aluminum deterioration. More older Japanese engines are ruined with improper coolant than I can write about here. Sensor damage is caused as well! You might take your car to the Toyota dealer and ask them to clean out the valve for you. Since this is only a 2 minute job, they just might do it for free. If they do, at least offer to tip the technician under the table. Be sure to power wash your entire engine bay before you take the car in. They will LOVE you for this!!!

- Q: my friend needs a flap valve replacement. does anyone no how serious this is, i dnt wanna lose my best friend?!!!

- pricey Vongirl, Congratulations on the lengthy lasting heart valve. frequently mechanical valves do not very last somewhat that lengthy. Mechanical, bovine, porcine and donor valves all positioned on out. It in basic terms relies upon on the timing. i'd say two decades with an same valve is somewhat magnificent. i wish, once you get your replace it lasts two decades besides!!!

- Q: My Dr placed me in the care of a cardiologist who ran some test and an echo scan reports i have a leaking valve but she failed to tell me which one and i failed to even think to ask. What are the results of leaking heart valves? I asked my mother and she says each one has a different result. What are they? Any help would be great. thanks.

- All of them equal greater stress on the heart, because if blood leaks in, then the heart fills somewhat beyond capacity and causes it to become stressed in the process of contraction.

- Q: Please suggest some design or sketch giving details of its operation. I need to operate valves on a natural gas pipeline with actuators to sense and operate the valve after recieving the signals from level switch in the system. Please help me understand the mechanism and operation philosophy.Please also suggest your email address as I may have to revert for subsequent questions on the same. Your addresses will be safe here and won't be passed on to any undesired sites. Be rest assured.

- Valve actuators are of various types namely electrically operated , pneumatically operated. Pneumatically operated actuators can be diaphragm operated for globe , gate valves. Pneumatic actuators can be quarter turn type for ball or butterfly valves. Pneumatic actuators can be cylinder operated for say Knife gate valves. Actuators are again single acting spring return type or double acting. Again actuators can be classified as on-off type or control ( modulating type). On- off pneumatic actuators can be operated with solenoid valves . As you mention the fluid to be natural gas, you have to select solenoid valves which are intrisically safe at the same time these valves may be placed at a safe distance from the valves and piping. These valves are again actuated by controllers( on -off , PID) connected to the level switches, pressure sensors or temp sensors as the case may be. To control flow rates, you need to use a pneumatic control valve with a pneumatic positioner operating on (0.2-1 kg/cm2) with current to pressure convertor or an electroneumatic positioner ( 4-20mA control signal). These can be used to control flow rate or downstream pressure. Other elements required are pressure or flow sensors, PID controllers. The control again depends on how the plant is operated ie DCS or PLC controlled. If it a simple requirement then the actuatar can be made to operate on a system of limit switches. While selecting an actuator the fail safe mode ( in case of power, signal or air failure) should also be taken into consideration , which is specified by words like normally open or normally closed etc. Avoid electric actuators as the gas is inflammable as a particular case.

- Q: Does the heater control valve anything to do with the A/C ?My heater control valve needs replacing, as it leaks when I put my truck's heat on. No heat, no leak. I have to periodically re-add Prestone every once in awhile after using the heat . I've checked the valve and it only leaks when I have my heat on, if I don't use my heat, I don't lose fluid. But now I'm wondering if I use my truck's A/C, does the heater control valve have anything to do with the radiator fluid, or just the freon? Thanks in advanceCar Mechanic in training

- What you may really want to check is if the heater core is leaking. I have never heard of a valve actually leaking. And no the AC and Heater are 2 different systems on a car. The fan that circulates the air is the same except air flows across the heater core or the air conditioning coil. AC air is usually just recirculated in the car air where heated air is usually outdoor air combined with in the car air.

- Q: One day i was cleaning my trumpet's third valve. when i tried pressing the key it was goig inok but near the end it gets stuck and gets unstuck like a second later.how can i fix this problem with out spending too much money?

- clean the valve and the tube the valve fits in. You will need to take the bottom cap off and with valve oil on a soft cloth (t shirt) wipe out the inside completely wipe down the valve with the cloth also. Clean the spring that pushes the valve back up. Use a tiny bit of vaseline and a liberal amount of valve oil on the valve. Replace everything. If this doesn't do it, take it to the repair shop.

Send your message to us

Pneumatic Safety Valve with API 6A Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 200 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords