Ball Valve For Heating SupplyDN 25 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

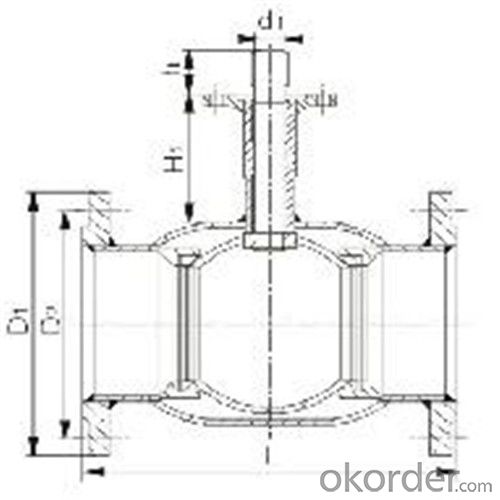

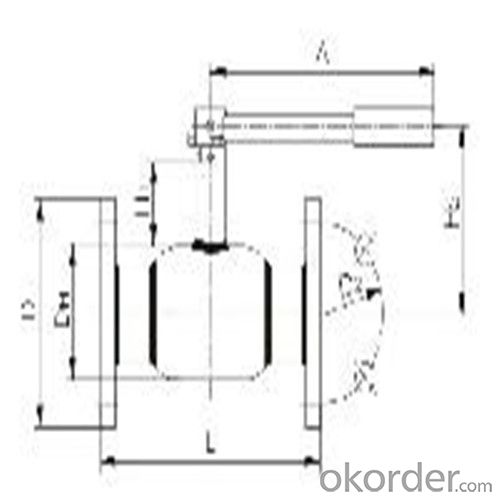

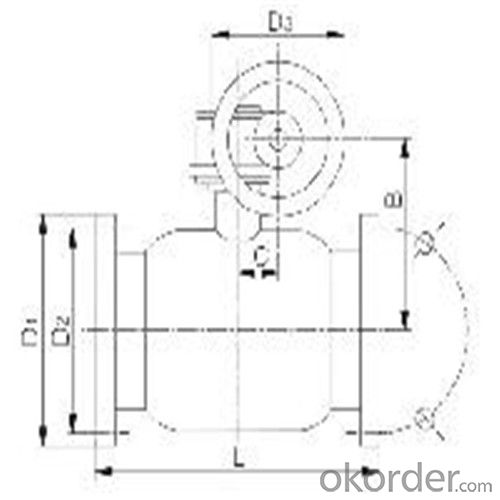

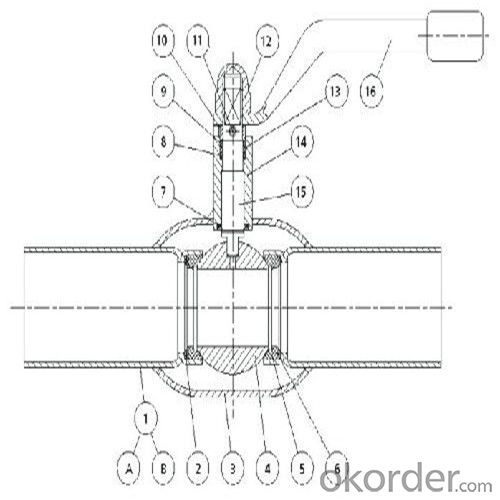

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: i have a 98 ford escort SE. oil spils out the dipstick. we think its the pressure release valve. sadly we dont know where that is. any imput would be great

- as they said, pcv valve. What you're describing is on a turbo- pressure exhaust valve.

- Q: Model 28 BS 12.5 HP engine intake valve sticks. Please advise.When under a full load like tall grass, it runs great, but when the load is not as heavy, the intake valve sticks open, spewing gas back through the carb and mis-firing.

- Are you sure that the valve is sticking or is the carburetor flooding?

- Q: I just bought a brand new rain bird sprinkler valve with flow control and when I turn the valve on automatically or manually it makes a loud sound that resembles a muted horn and when I close it, it makes the same sound but thumps at the end. Is this normal? Or do I need to get a new valve?

- Provided you are talking about the valve that controls flow from the constant on of water to the sprinklers, that also cuts it off, the turning on is a groaning of the built up pressure (normal) releasing into the sprinkler line. The thump only occurs at the end when you close it because it's slowly cutting off the pressure. Its more pronounced in the sprinkler valves because you are dealing with greater pressure than say when you turn on a sink or hose, in fact you can nearly mimic a more muffled version of the sound by using a hose, and kinking it or using a nozzle head. Having installed 20+ of these working with my Dad on his rental properties, I can guarantee they are not silent. Unless water is spraying all over the place, I'm 98% positive its a perfectly functioning valve.

- Q: I am trying to shut off the water valves under my sink to install a new kitchen faucet. The hand knobs appear to be damaged (thin soft metal). In addition, they seem to be seized up pretty well. So I can't shut them off by hand and not sure what I can use to close it off without damaging it further. My initial thought is to replace the valves. Any suggestions?

- You don't have to go through all that crap. Get a can of PB Blaster or Deep Creep. (penetrating oils) Both oils far away better than WD-40. Spray the stem of the valves and wait,..... about 20 minutes. if they are still stiff, apply again, wait another 20. Then if its not fine and ready to go, THEN go through the hassle...

- Q: i recently adjusted my valves on my 01 civic with a 1.7 sohc vtec motor and i did it to the specs under the hood and i didnt have them too tight or too loose on the feeler gauge and they are pretty loud are these motors just that noisy? has anyone else adjusted them to something different that works better?

- The dude above is physically powerful, yet incorrect on the fee. you may get an entire swifter equipment for about 1k, a reliable setup will fee a million.5k to 2k with injectors, gasoline pump, a turbine, and an intercooler. 01 are heavy and not super to do mods to, additionally d16 sucks inventory, so which you're able to additionally could desire to yet internals with expenses 900 for the aspects (pistons and rods). entire could be 2k to 3k for an extremely super setup for 250 to 300hp

- Q: Just wanted to know what the significance of the number of valves is?I know that theres valves for intake and exhaust if i'm correct.if there is four i'm guessing its 1 for air and 1 for fuel if its fuel injected. and 2 for exhaust?are there bikes with 3 valves or more than 4 valves and why?and a basic carburated 2 stroke just has an intake from the carb side and then an exhaust.please give me more info and let me know if i'm correct or not.

- It's two intake valves and two exhaust valves. The intake valves both have the same fuel/air mix going through them. It just gives the engine a bigger port to send the mixture through. Thus sending more fuel/air mix into the engine for more power. It's easier to fit four smaller valves than it is to fit two big valves into the combustion chamber. And the two exhaust valves give a bigger port to get the burned gas out of the combustion chamber faster.

- Q: The valves on our 2005 Pontiac Sunfire are bent and need fixing. Any idea of how much it might cost to have them fixed at a shop? Any estimates?

- Most mechanics will put on a rebuilt head -- if you were to buy it, they cost approx $350 for the head assembly.

- Q: 1st valve: this valve used to never cause me trouble at all. THen, suddenly it would stick at the end of the press. I took it home, washed it, cleaned out the casing with the casing brush, cleaned out the holes with a mouthpiece brush, and wiped it clean. Then, i put a bit of oil and it worked fine. Then next morning, i took it out for a second and found it was sticking again. It worked fine afterthat, but why would a valve to that?2nd: this valve is very troublesome. It's sticky for no reason. i did the same thing as the first, but it stayed stuck3rd. Weird valve. One day, i dropped my trumpet (not like down the stairs or anything, just while sitting) and this valve just messed up. What happened, was that when the valve was screwed in all the way, it would be stuck. however, when i unscrewed halfwayor a little less it worked amazingly well. Can a slightly unscrewed valve affect your playing (aside from the clicking noise). Can a valve get dented, causing this?

- I think the reason why your valves are sticking is because they are building up sludge from being oiled too much, and yes, that does happen frequently. Remove the valves carefully, wipe them off thoroughly with a clean cloth, replace them correctly, and lightly oil them. Then try pushing the valves a bit before playing.

- Q: As title.What's an easy way to remember: mitral valve leaflets are anterior and posterior leaflets; tricuspid leaflets are anterior, posterior, and septal (medial); aortic valve leaflets are left, right, posterior leaflets; pulmonary valve leaflets are left, right, anterior leaflets?It's easy to remember all but one valve (mitral) have three leaflets each. Physically aortic root sits behind pulmonary trunk, I guess that makes it easy to remember aortic valve has left, right, Posterior; and that pulmonary valve has left, right, anterior leaflets. Where I'm running out of ideas now is how to remember tricuspid has anterior, posterior and septal leaflets... Please help.Thanks.

- The tricuspid valve has three leaflets which are thin and membranous with commissures that appear more like indentations than true commissures. The TV apparatus is similar to the mitral valve but has greater variability and thinner leaflets. The three leaflets are the anterior, septal and posterior leaflets, with the anterior and septal being larger than the posterior leaflet. TV= tricuspid valve tri-cuspid=3(three leaflets) leaflets=3leaflets Tricuspid: Having three flaps or cusps. The valve that is called the tricuspid valve is situated between the right atrium and right ventricle and permits blood to flow only from the atrium into the ventricle. The aortic valve in the heart also has three cusps. Tricuspid valve (Anat.), the valve, consisting of three triangular membranous flaps, at the opening of the right auricle into the right ventricle in the heart of most mammals; -- sometimes called the tricuspid valves, each flap being regarded as a valve. Take care as always

Send your message to us

Ball Valve For Heating SupplyDN 25 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords