Swing Check Valve Wafer Type Double PN 10 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

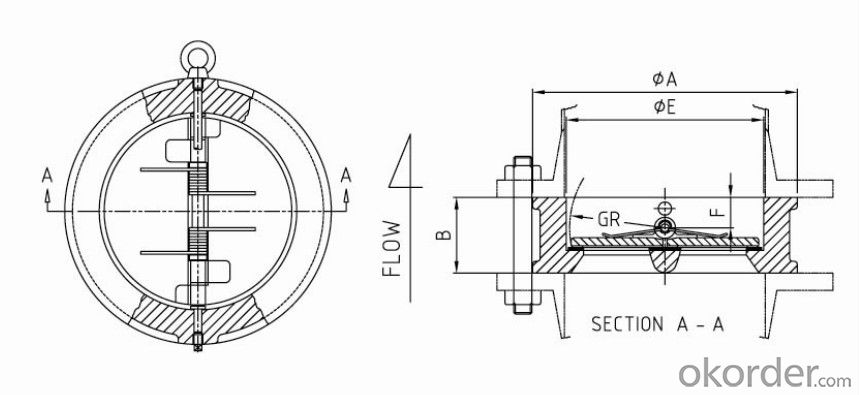

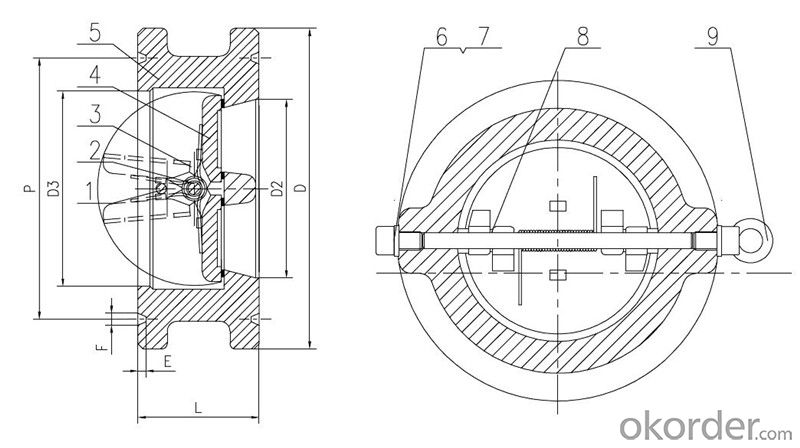

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Chev 350 in marine use. Made horiffic exhaust noise, especially with increasing throttle. Cam seems fine still, but the rocker on #5 exhaust was somewhat off to the side but still touching the side of the valve stem...but stem bent. What would cause this and is this the cause of the loud combustion sound (like a spark plug out of it's hole?

- make sure you dont have any of the spark plug wires crossed (like 5 7). If you do, you'll get a backfire out of the exhaust or carb.

- Q: I have a 87 cbr600, consumes oil at a considerable rate. Took the engine out of the frame and disassembled cylinder head, block and pistons and found there is a thick layer of cooked-on oil over all sixteen valves. I figured the oil consumption was due to bad rings, but could it have been the valves?

- I'm guessing the motor was running some blue smoke out the exhaust especially at start up. And I'm guessing it was probably a combination of rings and valves. She's twenty years old. Worn rings allow oil to escape into the combustion chamber from the underside of the piston and worn valve guides/seals allow oil to be burnt away from the top. When the guides/seals become worn or dry from age they allow the oil to leak down the valve stem. That's why you will notice them being worn especially at start up. While the bike sits it gives the oil a chance to pool at the edge of the valve to head surface so when the valve is first opened a accumulated amount of oil to enter the cumbustion chamber.

- Q: i have a 98 ford escort SE. oil spils out the dipstick. we think its the pressure release valve. sadly we dont know where that is. any imput would be great

- Yep...pcv valve. Couldn't really tell you where it is on a zetec but there should definitely be a haynes for your car (check your local library). Otherwise, other things (NOT RECOMMENDED!) you can do is release the crank/head pressure by drilling a hole through your oil cap threading a fitting on there and attaching a breather filter. It won't look good but it will work if you can't get to the valve. But you'll have to replace the oil cap once you actually fix the problem.

- Q: My Rodeo 96 has a P0440 code (Evaporative Emissions Control System problem). I have visually inspected the hoses on the engine; double-checked the gas cap is tight; but have not looked at the fuel tank sensors and connections. I've noticed that the EVAP canister purge valve solenoid is switching non-stop (click-click-click noise without stopping). Is it the expected behavior?

- P0440 Isuzu Rodeo

- Q: I replaced the valve cover seal and I wanted to know the torque specs for the valve cover bolts and the sequence it should go

- I have a Hayne's Manual that's for 2001 through 2003. It says to tighten all the valeve cover bolts to 40 inch pounds, initially. Then--when all are at that setting, tighten all of them to 80 inch pounds. Then when all are that tight, do the final tightening to 105 inch pounds. Sounds like a weird way to do it, but I bet it won't leak if you follow these directions .... Before doing this, apply a light coating of RTV sealant onto the corners of number 1 and number 6 camshaft bearing caps (I guess some oil will leak if this isn't done). In other words, the back corners as you're facing the engine from the front of the car. Tightening sequence: Do all the middle ones first, starting with the bolt in the middle of the valve cover, then the one just above it, then the one just below it. Then do the same sequence for the left three bolts. Then do the same sequence for the right three bolts. Then get a Hayne's manual, because it may not be perfect, but it shows a lot of torque settings and other stuff you will need in the future. I don't wrench all that often anymore, so I use a torque wrench. My bad!

- Q: 1990 5.7l with a .470 lift cam , is there going to be a clearance issue between the valve guide and the valve. Is the rocker going to bottom out on the guides and bust my heads.. If so what should i do.

- Get yourself a degree wheel and check. A valve stem usually has about 1-1/2 thousandths of an inch of clearance between it and the guide to allow movement and lubrication. Your camshaft has no bearing on this clearance. If you want a wild guess as to whether or not you might get coil bind in the springs, rocker bind against the rocker stud or even valve spring retainer smashing into the top of the valve seal then my guess is not, not with just .470 lift. Probably would take more like .500 for any of that to happen.

- Q: i have seen the wrting M/T on some valve covers and was wondering what that meant

- Yep those are the old Mickey Thompson valve covers. He was a great drag racer and tire maker. M/T slicks are one of the most used tires in drag racing today. He was murdered (shot IIRC) around 30 years ago by a hired gunman that his biz partern hired to gun Mickey down

- Q: I am a junior piping engineer. I want to know what is the meaning of term Triple Eccentric in Triple Eccentric Butterfly ValveButterfly Valve. So kindly enlighten me.

- Good question but I think I found your answer. Hope this helps. Triple eccentric means:- 1)First eccentric is the offset between the shaft centre line and the disc trunnion centre line. 2)Second eccentric is the offset between the body centre line and the disc centre line. 3)The third and the most important is the eccentric in the sealing(multiple) itself such that if you draw a imaginary contour line between the sealing shape vs the body centre,It becomes a cone with one side flat on surface.(I hope my words are clear enough to make you understand). The reason for this shape is because it gives better sealing ability for the valve.eg:- Fire safe valves are triple eccentric valves which are also called pyrogenic valves.The sealings are multiple in nos. and together they form a pyrogenic shape therefore this sealing is also called pyrogenic sealing.

- Q: where is the heater control valve on a 1996 volkswagen passat

- i'm no Ford fan, yet a Mondeo resources of a similar fee might want to be my determination. Neither Passat or A4 are fairly good, and service prices for VAG diesels are astronomical. once you're insistent on an A4 or a Passat, ?a million,00 is going to get you a finished smash till you're prepared to spend a lot of time being dissatisfied by utilising the final public of autos on the marketplace.

- Q: Hi everybody,I need some information about the operation of a double solenoid valve and how to control it using a PLC

- A double solenoid has two solenoids, and when voltage is supplied to one (and not the other) the valve shifts. Note that if voltage is supplied to both solenoids at the same time, the valve will stay in the position is was in (i.e. it won't shift since the solenoids will be working against each other). This is typically not desired, so make sure you remove voltage from one side when supplying it to the other. If no voltage is supplied to either solenoid, the result will be the same as if voltage is supplied to both, in that the valve will stay in the position is was in. What this means is that the cylinder has no home position, so when power is cut, the valve will stay where it was at that time, and the cylinder will continue to do work in the direction is was working in. Again, depending upon what the cylinder was doing, this may or may not be desired. For Conrolling with PLC you may need to wire two discrete outputs of PLC to those two solenoids using relay. And the ON/OFF those two outputs as required.

Send your message to us

Swing Check Valve Wafer Type Double PN 10 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords