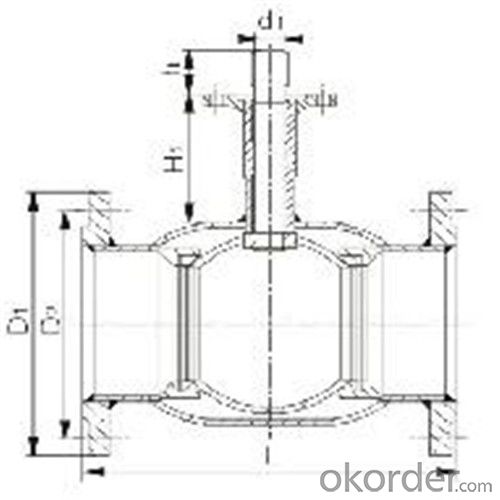

Ball Valve For Heating SupplyDN 100 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

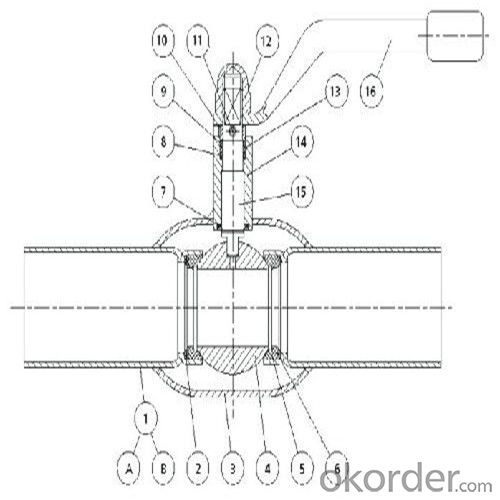

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

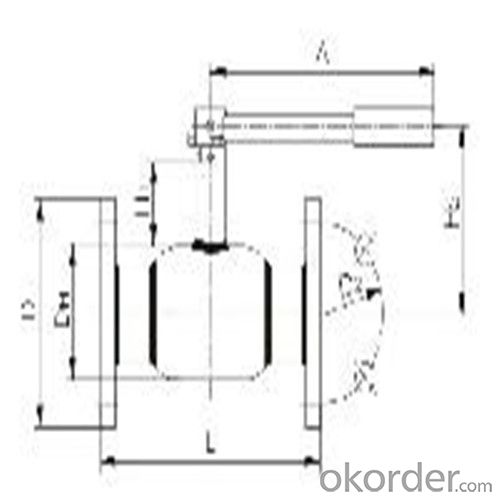

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

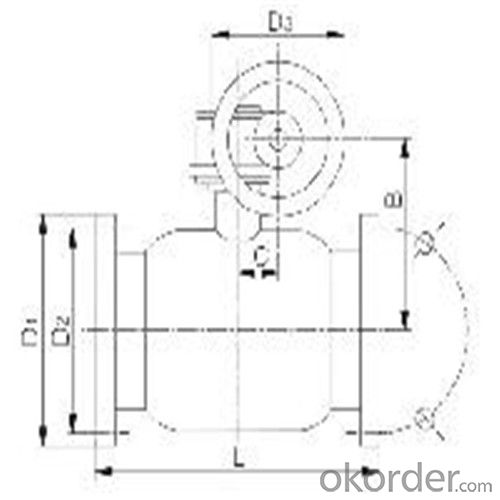

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: what are the best aorta heart valves. mech. or animal.

- Depending on the valve, the original valve may be able to be repaired. This procedure has only been widely used 8-10 years probably. Originally it was believed that these like animal (pig or cow) would probably only last around 10 years but it is constantly being adapted so longer may be possible. Animal valves do not require blood thinners, although many people I know have ended up on thinners because of other problems. The other advantage is that they are quiet. Mechanical valves, often called metal aren't always truly metal. Older valves were thus a scan using an MRI was not possible. Mine was put in during 1995 and is called metal but does not cause any problem with an MRI and I know others from that time frame also with no problem. I expect it to last my whole lifetime and I never needed any anti-reject meds and few people I know have. I do tick like an old watch especially when I get winded or tired, but over the 13 years I've had it only one person outside of medical professionals examining me have ever noticed. It doesn't keep me awake but I do know some people who notice theirs, but the newer the quieter. I do have to take blood thinners, but for me and most of those I know don't have major problems maintaining a therapeutic level. You have to have a blood test routinely to know but they now have a finger prick machine so it is quick and easy. I only know of one person whose body rejected valves and had to have it removed and animal placed in. From those I know usually children they will do tissue just because a child won't be as careful and watchful of bleeding. Otherwise it is choice based on years wanted from the valve and lifestyle if meds fit and eating habits.

- Q: The timing belt in my 93 honda accord went out going about 45mph,i then paid someone 150 dollars to put in the new timing belt and it began to shake and he told me that the valves were bent.....i went to a local mechanic and he told me that the valves in honda accords dont bend...is this true?and how much is an average cost to repair the valves and pay someone to do all this?can i do it myself?

- hey, the same thing happened to my car ok, you can fix it but it will take you a lot of time first, you will need to remove all the components such as alternator, exhaust headers , intake and head cover since you paid to get the belt put on, go ahead and mark it with a white out pen so you know where each tick mark goes and you dont have to pay again now you will need a deep 14 inch socket and a torque wrench ( can be borrowed from autozone ) now remove the 14 bolts carefully and lift the head straight up now that you have the head out, it is a good time to replace the head gasket as well take the head to a local machine shop and have it rectified now in a closed area remove the valves and valve covers and put in new ones then its just a matter of putting everything back together I wish I could help you cuz I know it sucks when this happens But go ahead and buy the Chilton book at your local Autozone and it has step by step instructions I took me about a week the first time I did this, and i was just a novice trying to avoid big charges :)

- Q: Situation: The males in my family have mitral valve prolapse, while I do not.If anyone could answer some of the following questions, it would be amazing! Thank you so much!1. Is this an X or Y chromosome disease? (I thought since it was just guys, it'd b Y)2. If so (or not), is there any reason why I don't have it?Thanks again! (:

- Dear Madam, I am a cardiologist sending this article for you. Hope it helps you. Mitral valve prolapse, sometimes called MVP, is a common heart valve disorder. The mitral valve is between the left atrium and the left ventricle of the heart. It has two leaflets (flaps) that control the blood flow. MVP occurs when one or both of the leaflets are enlarged or have extra tissue. MVP is usually harmless. However, major complications can occur, including a blood clot in the brain and an infection called infective endocarditis involving the mitral valve as well as other valves. MVP appears twice as often in women as in men. It is most commonly a hereditary disorder. Some people with MVP have no symptoms. However, most patients experience a rapid or irregular heartbeat, shortness of breath, light-headedness, and chronic fatigue. Many patients also suffer from migraines, eating and sleeping disorders, an overactive or inflamed thyroid gland, diarrhea, and cold hands and feet. Emotional stress often magnifies the symptoms. Doctors generally prescribe regular exams and aerobic exercise for people who have MVP. Patients also are advised to restrict their intake or use of high-carbohydrate foods, caffeine, and decongestants. Some patients may need beta-blockers and specific antiarrhythmic medication. More severe cases may require surgery to repair or replace the valve or to insert an electronic regulator, such as a pacemaker or defibrillator.

- Q: My husband went to the doctor today, then called to say he won't be coming home because he has infective endocarditis. They sent him to another, larger, hospital in the region. Hours later he called and said that he needs surgery on the valve and they are moving him to another part of the country. I've been trying to read about it but I'm not sure I understand. What I've read says that they have to treat the infection with penicillin first, the he can have surgery. However, he's telling me he might have surgery when he get to the other hospital. He needs a new valve. Does this mean that his condition is worse than those I've read about or that they are simply doing things differently? Also, if you know. Does other illnesses make the risks much higher? He's got aspergillus in his lungs and have had 2/3 of the lungs removed. He has an immune deficiency (HIES) and he is physically weak from being sick. I know it's not good, but how bad is it?

- Infectious endocarditis. Of course, any endocarditis is an infection. Rather like saying an 'infectious cold.' You will need to discuss this with his doctor to get good information. That means you go where he is. If you need to you make an appointment with the doctor at his office to find out. No way to know what kind of heart value issue he has or what other kind of heart condition he has.

- Q: I was wondering if the pressure relief valve can be vented right under the house or does it have to be ran to the outside of the house. Also is there another method such as a catch pan that I can employ? I live in Washington.

- Most codes state that it must be vented to the outside.Check with your city code enforcer or county office.

- Q: One of the zone control valves in my heating system does not appear to be working. The thermostat is calling for heat, but no water is flowing. If the other thermostats call for heat, the valves seem to open as the pipes above the valve get hot from the water flowing through. The one that appears busted gets luke warm at best. All 4 valves in the system are fed from the same pipe, and the failed valve is the third in the series of 4 along the pipe (and #4 flows fine) so it doesn't appear to be something in the feeder pipe.Is there anything I can do to try and fix the existing valve, can I replace the valve myself? Would replacing the valve top of the valve (the green/gold portion) possible fix the issue (maybe a problem with the operation of the piston? Is there anything I ahve to do before removing the valve top aside from removing power to the valve?

- By your description it sounds like you have a Taco zone valve, if so, you can twist the top, (head) and it disconnects from the valve body, you could swap it with one of the others to prove good or bad before you buy one, there not cheap.

- Q: I went to turn the water off with the shut-off valve so that I could do some work on the toilet tank (replacing old and leaky fill valve) but the water won't shut off. I'm assuming that I'll need to replace the shut-off valve itself but could anything else be causing the problem? The funny thing is, the leaky fill valve that I wanted to replace has now stopped hissing and leaking and the tank seemingly fills fine. But of course the water can't be turned off completely.Just wanted to check make sure that there aren't anything else I should do or consider before I went off to replace the shut-off valve.Thanks

- No. Very simply if the toilet shut-off valve doesn't stop the water flow, it is faulty and should be replaced. However, the shut-off valve is only used to service the toilet, and if your toilet is operating okay, don't mess with it. If you're not that ambitious, the next time you need to service the toilet would be an opportune time to change the valve. Good luck and God Bless!! Steve

- Q: I took my 2nd valve out to wash it (i couldn't find my oil, but it worked fine) and I've tried making the number face the mouthpiece, yet it still is messed up and won't let me play a lot of notes.

- 1) Try this first and if this doesn't work, go to #2. Oil the valve's body and gently put it back into the cylinder without screwing it in yet. Then, turn the valve until it clicks, and make sure it is really seated correct. Some trumpets have two clicks, and one is not the right one. So, you have to get the right click - which tells you that your valve is seated right. When your valve is seated right, then screw it in. 2) If you don't get a click when you spin your valve - look at the tubing on your trumpet and line up the holes in your valve with the tubing. When the valve is up, it will line up with 2 holes of the tubing, and when it is down it will line up with 2 other holes in the tuning. So, you can determine the correct positioning of the valve by looking at the tubing on your trumpet. But this is a last resort. I've never seen a trumpet where the valves don't click when you turn them.

- Q: I have a trumpet, but unintentionally dropped it. When I started playing, I noticed that the first valve was very sticky. Therefore, I decided to put some oil on it. Despite the oil helping a lot, the valves are still sticking a bit when I push them down, as the key still stays in the valve for a few second before coming up again. It could possibly have a slight dent, but when I opened the valve, I did not see any damage at all. Are there any suggestions? And if it is dented how much would it cost to repair it?

- My valves have had many issues over the past few years. Your problem is either 1. horn is dirty 2. there is a tiny dent (even 1/2mm is enough to stop the valve, happened to me last month). If your horn is dirty, there are plenty of youtube videos on how; it generally involves using water and rising all the gunk out. You could also have too much oil buildup. If there is a dent, don't even try to repair it yourself--it is waaaaay to hard, and you'll ruin the instrument even more. Take it to the store; it should only cost $20-30. I suggest you clean the trumpet first and then try to get it fixed if it is not good.

- Q: I am looking for a full valve guitar amp for around ?300.It needs to be loud enough to play with a quietish drum kit.Currently i have looked at an epiphone valve senior in both and combo and cab and head form. i have also looked at some smaller amps such as the vox ac4 but am a bit worried about its small size. any advice would be greatly welcome. many thanks in advance.

- Well I have the Valve Jr. and the AC4. The AC4 is a good sounding amp, but even though it is only 1 watt less, the Valve Jr. is much louder. The AC4 is a great practice amp but not enough to jam with a drummer unless he is pretty quiet and you really crank the amp. Never heard one of the new Valve Sr. models but with all of the goodies they added it should sound really good. I had my Jr. modified but it still doesn't have all the cool stuff the Senior has. I think you would really like the Epiphone and at 20 watts you will be more than loud enough. My 5 watt Jr. will get very loud. All I own are low watt class A valve amps, it's the only way to fly!! The Marshall Class 5 might be worth looking at also.

Send your message to us

Ball Valve For Heating SupplyDN 100 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords