Fixed choke valve with API 6A Standard for Oil Field Usage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

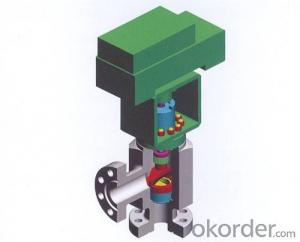

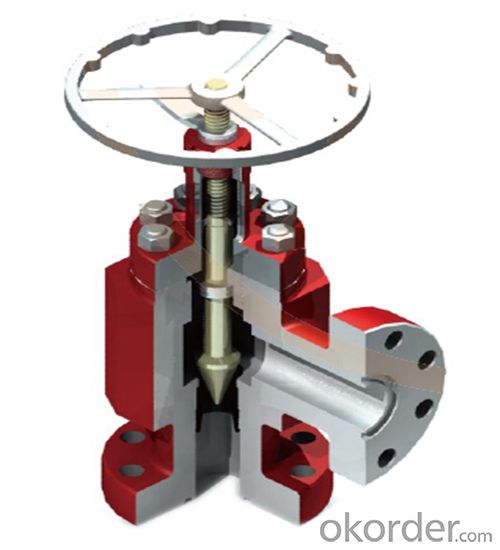

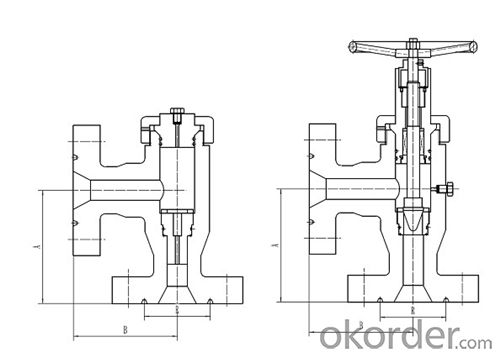

1. Structure of Fixed choke valve Description

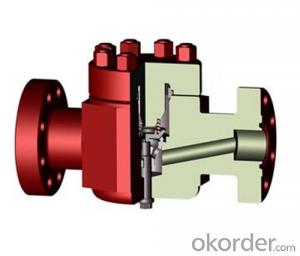

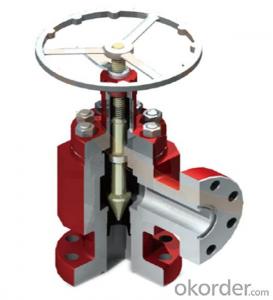

Choke valve as the main parts of christmas tree and manifold, it is mainly used for controlling the wellhead flow and its level of work pressure can be up to 15000 psi. Choke valve can be divided into adjustable choke valve and fixed choke valve.

Fixed choke valve is the main parts of the wellhead and christmas tree equipment, through special tools to replace the size of the oil nozzle, and transform the throttling area of the liquid to control crude oil production of the wellhead

2. Main Features of Fixed choke valve

1) With competitive price and high quality.

2) Meet API standard.

3) Meet your special requirements.

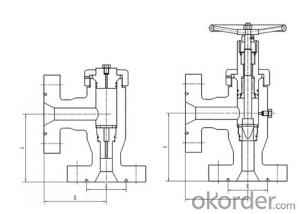

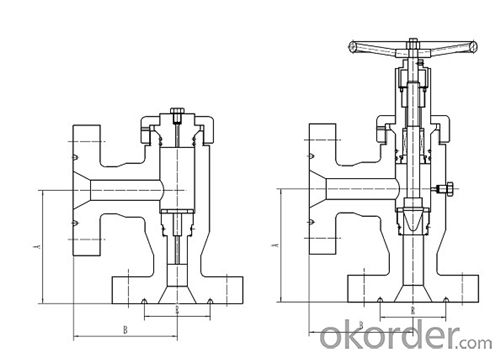

3. Fixed choke valve Images

4. Fixed choke valve Specification

Working Pressure:2,000Psi ~15,000Psi

Nominal Diameter:2-1/16″~4-1/16"

PR Class:PR1~2

PSL Class:PSL1~4

Working Temp.:KU (-60℃~121℃)

Working Medium:oil、gas、mud

Material Class :AA~HH

End Connection :connecting with ANSI and API standards

Nozzle aperture :Φ3, Φ4, Φ5, Φ6, Φ7, Φ8, Φ9, Φ10, Φ11, Φ12, Φ13, Φ14, Φ15, Φ16

5. FAQ of Fixed choke valve

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in values products in China, can offer series of values to around the world.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: after my hot water tank shuts off about 1/4 cup of water comes out therelief valve. i changed the relief valve. the tank is 6 months old

- Do you mean the heating (burner or heating coils) shuts off. If that is the case then you may need an expansion tank. If there is a reverse flow valve at your meter (most locations now require this feature to prevent back flow of water to the main line.) the pressure in your system can build up higher than normal when the hot water tank is heating. Most systems have a small expansion tank installed near the hot water heater to deal with this problem.

- Q: I know what a blow off valve is but where does it blow out the air out off does the air blow out threw the exhaust or what?

- It blows out in to the air.

- Q: Is it posible there is underground valves? I looked all over my yard and can only find2 valves.???

- Factor is, we weren't there, and nothing is recorded about it, rather then what you're quoting. As for evidence - the earth sure has shifted around rather a lot because the opening. If there was once a first-class flood, when the waters gushed up from the deep as in a nice catastophe, tossing things about into layers far and wide the earth, the evidence won't appear like what you are watching for. What are you looking to disprove or show by way of this question?

- Q: will adding a bypass valve onto an air filter effect gas milage or horsepower?

- bypass valves are for cars with forced induction IEturbocharger,supercharger it allows the air that would normally be expelled into the atmosphere blow off valve and instead putting it back into the intake which helps with less lag in building boost again. If your car is not turboed or supercharged then forget it.

- Q: How can I tell if my 2004 Ford Taurus a 12 or 24 valve?

- 12 Ford Taurus

- Q: Is a Head gasket the same thing as the valve cover gasket, on my honda civic si?

- Head gasket is between the head and block. It's primary job is to cushion between the two, dealing with high temperature and pressures of combustion process. So it helps in maintaining combustion chamber pressure, sealing coolant, sealing oil passages between the two parts (head block). Requires major disassembly to replace if needed, and may only be part of a larger looming problem in the motor. Valve cover gasket is between top of head and valve cover. For your Honda, it involves a large rubber/neoprene o-ring that fits in a groove channel in the valve cover, specially formed for the shape of it. Also with it, should change out the other smaller seals that go around the spark plug tuges, and valve cover hold-down studs. If you have oil leaking around the outside edge of the valve cover and in the spark plug wire tubes, you can buy the set and have it easily replaced or do yourself if have the tools skill.

- Q: I want to change a stuck pcv valve on my 86 toyota pickup 22RE. I've used tons of lube and picked away at the grommet but i still can't get it out. Any advice?

- the grommet is being replaced so do what you have to to get the valve out. id grab a hold with a pair of pliers and go that route.

- Q: I had some great answers to my question yesterday... I have decided to have the valve job done... Since I have decide to go this route... I need some reassurance, the few people I have suggessed this option to have now told me that typically after a valve job other problems will start showing up. They have said that the car isn't worth putting money into and to get ride of it.

- Getting a vlave job done isnt going to hurt your car at all, nor your motor. Make sure you have a reputable machine shop do this (most garages dont have the tools for it). If a 3 angle valve job is done correctly and new valve stem seals, retainers, and spring are all carefully installed to manufacturer spec then there should be no problem at all. Many shops will do a sloppy job grinding the valve face (which is a hard thing to get the knack for) and will install to valves without another thought. When new valves or old valves with resurfaced faces are installed the spring rate of the valve springs needs to be checked to ensure are srpings are the same strength. Also once installed, the height of each installed valve/spring needs to be checked to make sure its in the specified allowance. If valve seats and surfaces are all done correctly along with a profesional installation I wouldn't worry!

- Q: What are Atrial valves??

- I've heard the term sometimes (though rarely) used instead of atrioventricular valves, the tricuspid (right) and bicuspid valves.

- Q: Hi all,My buddys ford 460 has stuck valves. Where do I start? Could I notice anything by removing the valve covers, or do I have to remove the heads? Is it possible to unstick them without removing the heads? Assuming they stuck from sitting. What's the chance it bent the pushrods if it was running when they stuck? Can I check this without removing the heads? I'm not too familiar with this engine.

- a valve stuck in the open position when cranked by a starter motor can put a hole in the piston it depends on which 460 7.5L you have some are flat top some are popups where centers are raised ive seen both in stock motors motorhead is right you can free them but you'll wanna soak them down constantly for a week or so remember they didnt get like that over night DO NOT crank over with starter use bolt on balancer as you'll feel resistance should you encounter a stuck open valve its so much easier with heads off but you can see the guides by removing valve covers if your valves are stuck your guide seal are junk trust me

Send your message to us

Fixed choke valve with API 6A Standard for Oil Field Usage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords