API Cast Steel Check Valve 80 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

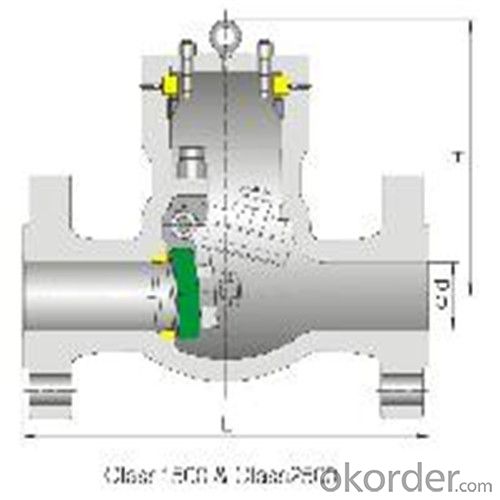

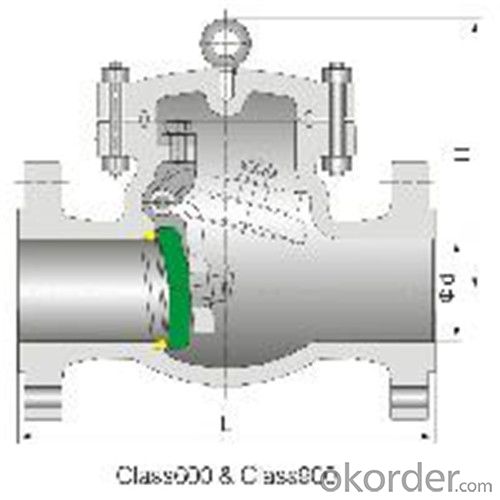

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: We live in a four story sixteen unity apartment building. There are two radiators in our apartment. The on in the living room is large and we can't turn it on with out water coming out of the little valve on the end, which I am assuming is there to release excess pressure. It doesn't matter if we leave it on for an hour or two days—water still comes out. It has warped the wood below it.How can I stop this? I would really like to have heat on both sides of my apartment.Thanks!

- Melvin S is correct. But check to see if the valve is closed first.

- Q: The pump is working fine on the presta valve on my back tire, but it is not working on the other presta valve. It seems like the the presta valve isn't sticking out far enough out of the tube for the pump to be able to lock in on it. What could be causing this?

- to apply the adapter, you need to first unscrew the presta valve, then placed the adapter on and pump up the tire, then take the adapter off and tighten the presta valve to close it. I consider the different answer that that's recommended to replace the tubes so as that the presta valve does not come aside. New tubes are inexpensive - approximately $6 or so. you need to purchase a spare, too, merely in case you flat. in case you do no longer understand the thank you to alter the tubes, your community motorbike save can do this for you and clarify the technique so as which you're able to do it your self interior the destiny and sell you the tire levers (and patch kit in case you want) you will ought to do it. reliable success!

- Q: My question mainly pertains to Electric Motor-driven Motor Operated Valve Actuators.

- The motor drives a gear operator on the valve and is limited in the degree to which it operates by a set of limit switches so it doesn't over run or over torqued the shaft. This arrangement typically also has another set of limit switches that indicate the open or closed position so the person controlling the valve will know its position. This type of operator is typically used on ball, butterfly or plug valves but can be used on gate valves.

- Q: We have a wall mounted shower head as well as a ceiling mounted shower head. Suddenly the turning valve for the wall mounted head does not work, only the ceiling one does. Is this stripped. Can it be repaired with a marble wall? I have a photo if needed. Thank you ahead of time. Patrick

- The mixing valve is in the handle that turns the water on. You don't need to take down the wall to get at it. The handle come off including any cover plate and the valve is right behind it. Be careful not drop/lose any screws or washers. They are small. The home center sells replacements for certain brands so get that information.

- Q: How do you repack an osy valve? Where do you get the packing from? Do you have to shut down the water to do it?

- where is i get the packing gland material

- Q: Are all the valve created games tied together somehow? Except for TF2 like in portal 2 glados says she might start a hobby of reanimating the dead so is that left 4 dead?

- no or i thinks GLADOS PRO PROPOSED

- Q: I am modelling the production of phthalic annhydride and my process has a lot of FIC, LIC, PIC notations in circles on the connections. Moreover there are what i think are temprature and pressure notations in a square and a triangle. But most primarily what does a pneumatic valve do?

- pneumatic valve is nothing but a valve which is operated with the help of high pressure compressed air. the can be thought of as an alternative of a metal spring... These could retract valves more quickly and reduce the possibility of piston-valve interference as long as pressure could be maintained. Additionally, the amount of seat tension required to keep a coil sprung valve under control results in greater peak lift loading, with added stress to the entire valvetrain as a result.

- Q: Is there a relationship?

- From personal experience yes it can. My mothers hemoglobin dropped down to 8.0. The Dr said it was because of her stenosis in her aortic valve causing her to bleed in her abdomen. She had her heart surgery and it came back up, just like the Dr said it would.

- Q: The pig heart is better than our heart but the valves can be used to help us.

- I have had heart surgery and they ruled out replacing my valve with a pig valve because they only last about 5 years. They replaced mine with a mechanical valve, and so far it's amazing! If they replace your valve I believe they basically cut out the defective one and sew in a new valve, animal or man made. If replaced with a pig valve you must be on anti-rejection medicine, and have it replaced every five years or so. With a mechanical one you have to be on blood thinners, but they assume (last I heard) they should last a minimum of 40 years, probably longer.

- Q: This trumpet has been in storage in its casing untouched for about 5 years. I took it out and tried to play it but only air comes out and no sound. The 2nd and 3rd valves are hard to push down. What do I do to fix it? Thanks!

- Dis is a pretty common problem. The valves are in the wrong valve case or they are turned aound in the case. Take each valve out and check the number...... most have a number stamped near the top, or on the part around the spring. Get them in the right place with the notch in the case matching the little peg on the side of the valve and all should be well. By the way, if you can't get a buzz on the mouthpiece the whole problem is you alone.

Send your message to us

API Cast Steel Check Valve 80 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords