API Cast Steel Check Valve 50 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

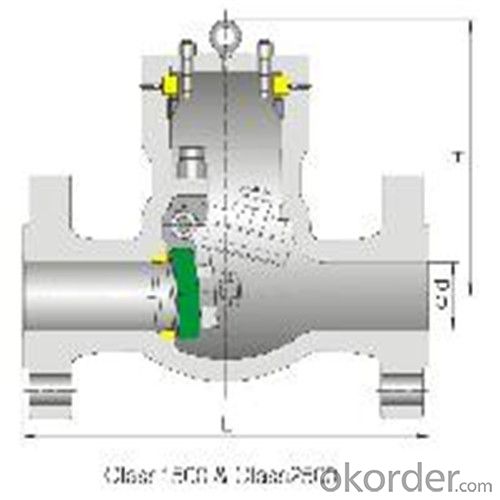

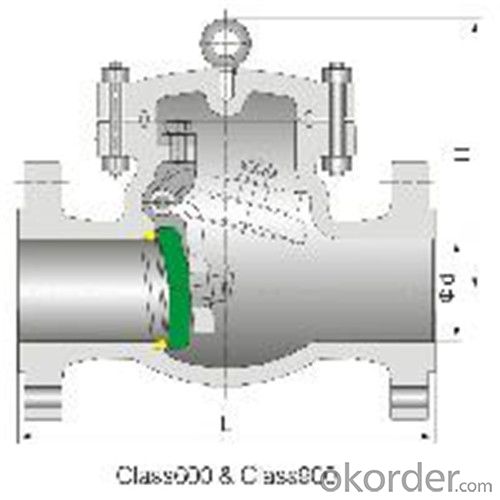

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check="" valves="" and="" welded="" on="" seat="" can="" be="" also="" optional="" if="" being="" requested="" by="" the="" customer.welded="" is="" used="" for="" nps="">12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Can you please explain to me what an atrial valve is and what it does??

- Only Veins have Valves that's in order to keep blood pumping inside, with the help of Skeletal muscles. About Atrial Valves, there's a valve in the Pulmonary artrey only.

- Q: I bought a plastic ball valve from Lowe's just a couple days ago and it is stuck, I haven't installed it in anything but it wont budge without a pair of channel locks. I tried wd-40 but still nothing, should I return it or keep working with it? and if I keep working what should I try?

- === take it back and get another valve .... if it doesn't work freely in your hand then the valve will be a problem if you install it ---- working with pvc you should use the purple glue that is waterproof and it is a good seal and no leaks when you have

- Q: I had the EGR valve and solenoid replaced and I'm not sure they needed to be replaced.

- The EGR valve diverts exhaust gas back into the intake manifold to take up space and prevent the formation of NOx, a polluting gas formed inside the cylinder at temperatures above 2500 degrees.

- Q: Ford Capri 2.8 injection. I need to adjust the valves, so need to know how to tell if the valves are tipping and at what exact time I need to adjust them.

- valve tapping what is valve tipping search yahoo answers for valve tapping i saw a resolved question about how to fix this problem

- Q: How come my boiler supply valve isnt letting water into my boiler, i have a cold water supply hooked up to it with the valve on i have tested the copper pipe goin into it and water flows into it, but when It reaches the valve it stops. I understand that it my have a backflow preventer in it and I am wondering if that could be malfunctioning. The hole you see on the front is where my expansion tank screws in. Also where could I get a new Valve. Thanks.http://img149.imageshack.us/i/boilerfillvalve.jpg/

- I work on antique steam boilers and engines for a hobby and if your supply valve isn't letting feedwater into the boiler, I'm going to tell you right now that you potentially have a VERY dangerous situation on your hands. Until you get this issue resolved, I would recommend that you not steam this boiler up under any circumstances, unless you have a backup feedwater delivery system that is working correctly. Many people don't know this, but a low water condition in a boiler under steam is essentially a ticking time bomb and can result in a fatal explosion. As to what may be causing it, I would say it's possibly one of two things: 1.) The check valve has been installed backwards and the flow of water is basically pushing it shut. 2.) The check valve is installed correctly, but is frozen shut due to corrosion and scale. Either way, I would have a certified boiler inspector come out and take a look at it; he can probably tell you more than I can.

- Q: here are pix's i want to no, if there is a easy fix or does it have 2 b machined thanksi think it use to have a bent valve in it

- hard to tell looking at your pic,s. your best bet is to find a trust worthy machine shop...they can tell you if they can be lapped or if they need replacing...newer heads have hardened valve,s seat,s..if damaged they should be replaced ...valve,s , seat,s , guide,s , valve seal,s , possible rocker assembly,s , lifter,s , push rod,s ,Etc......best of luck!

- Q: My car has been sputtering and hesitating when I hit the gas. My friend's boyfriend says it is a bad erg valve does that sound right?

- Its EGR vavle. it is an emissions administration gadget. It stands for exhaust gasoline recuculation. It sends countless the exhasut from the engine returned by using. it is going to reason your difficulty. it is user-friendly because of the fact they gets clogged with carbon over the years and stop working. i might replace it to save on gasoline and it isnt extraordinarily expenisve to do or have completed.

- Q: My third valve won't move at all. I haven't played my trumpet in a while and I tried to oil it to get it to unstick but it still won't move at all. People say to screw it off but I can only unscrew the little cap at the bottom of the valve where you push in, not the white button at the top. Help please! Thank you so much! =]

- i got here across that Dennis Wick valve oil is a procedures more advantageous ideal to any that I easily have used. you'll locate it on Amazon. If cleansing with dish cleansing soap and heat water would not artwork, alongside with the Dennis Wick oil, I recommend that you're taking it to a restoration shop. be careful at the same time as cleansing now to not get any cork or felt moist. only dip the truly valve section into the water.

- Q: Dr says I have a leake heart valve. Should I be concerned?? He doesn't think so but I am worried. Should I get a second opinion? I am 53 and a diabetic. Has any one ever had this problem?

- I was diagnosed with a leaky heart valve at age 18, they did regular tests but only once a year, they then found an aortic aneurysm (bulging in main heart pipe) after many years i had surgery at 47 ! i came out of hospital 10 days after op. i am fitter than ever or i will be when i have my hip replacement later this year. so don't worry IF you have to have surgery its not that bad !

- Q: I have just been diagnosed with a Mitral Valve disorder. The Doc's notes say Trace Center Regurgitation. Also Trivial Tricuspid Regurgitation. In simple terms, what do these things mean, what causes it, and how do you treat it?

- If there is regurgitation but it's minimal, you likely have little to worry about. Mitral Valve disorder is commonly known as a heart murmur. Many people have them. It's only when there's regurgitation involved that it becomes more complicated. Since yours is trace and trivial it definitely requires investigation. At some point they may want to do a repair of the valve or a replacment but that depends on the degree of regurgitation. Regurgitation simply means that the valve does not close properly when the heart pumps out blood. It is the abnormal leaking of blood from the left ventricle, through the mitral valve, and into the left atrium, when the left ventricle contracts, i.e. there is regurgitation of blood back into the left atrium. Treatment will depend on the severity of the regurgitation so it's something you'll need to discuss with your doctor/specialist.

Send your message to us

API Cast Steel Check Valve 50 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords