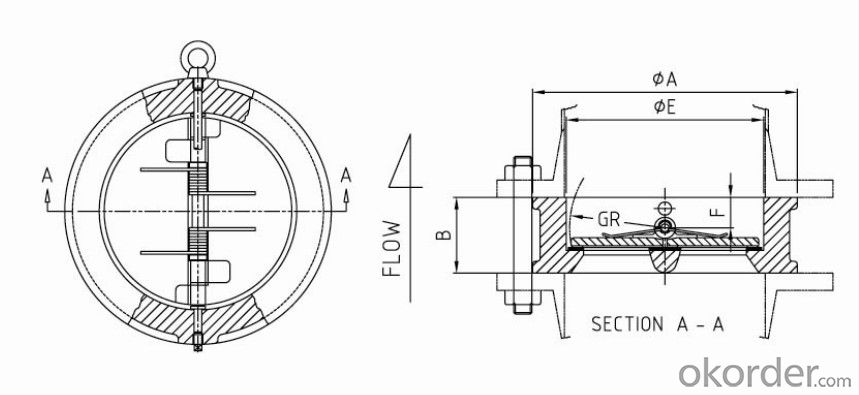

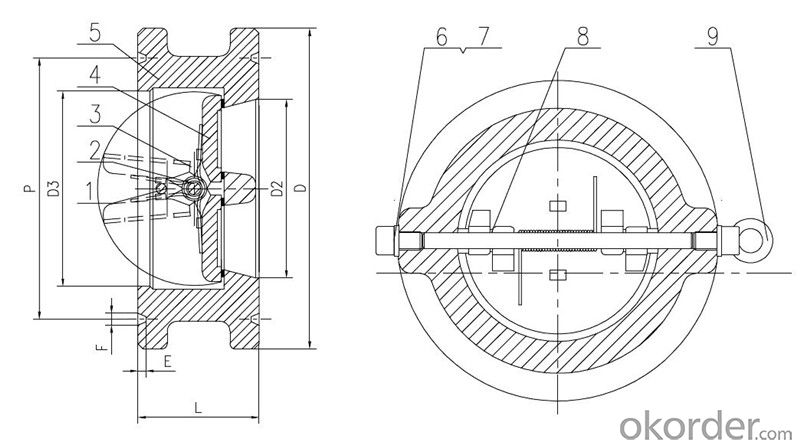

Swing Check Valve Wafer Type Double Disc DN 100 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: what is the average cost to replace a valve core on a car? also can any car shop do it or do i have to go to a conrads etc.

- You can do it yourself very cheaply. All you need to do is go to Walmart or a Auto parts store and get four valve cores and a valve core remover, then go to a gas station the has a air compressor. Remove the valve cores and put the new ones in, you don't have to let all the air out Just put the new valve core in and air the tire back up. I would check the old valve cores before I changed them or have them changed by mixing water and soap together and put in on the top of the valve core, if it bubbles then you need to replace them, if it doesn't bubble someone is just try to scam you.

- Q: How much would it cost to get a new valve cover gasket on a 1993 Nissan Quest van?? I know of a van for sale, but they said it might need a gasket soon. How much plus labor, average, do you think it'll cost? Thanks!!

- www.okorder /

- Q: Our water heater (bought in 2007 so still fairly new still under warranty luckily) seems to release water from the pressure release valve quite frequently. Everyone seems to say that it shouldn't do it often and ours probably does it a couple times per day. 2 main questions - 1. Is there really a risk of too much pressure building up and the water heater exploding (that's what the sales guy at Lowe's said) and 2. Any idea what the problem might be/what we should check out?

- I doubt that there is any chance of the water heater exploding since the safety valve is leaking. Have you checked the water temperature settings? After no hot water has been used for a while, run some hot water and check the temperature. If it is near boiling, the you need to check the settings. It could be just a faulty relief valve which leaks when the water surges. When there is high water flow that stops suddenly the water pressure will surge for a very short time. Try opening the bath tub faucets fully and then shut them off quickly while some one watched the heater to see if it leaks. I hope this helps.

- Q: also are those air flow limiting valves safe for the air pump to reduce the flow of air, I have one because the air bubbles are just way too many without one and it scares the fish away

- a check valve is to prevent back siphoning of water into the pump if you have a power outage or unplug the pump by accident. I'd suggest checking it by blowing through it the wrong way; if air does pass through get a new check valve (check new ones to be sure they don't limit airflow too much, and that the close in the wrong direction, many are cheap crap and don't work the day you buy them, so check them before you leave the store with it...note: same with thermometers, compare them with each other so you don't get the one that's crap) what you want is a normal air valve, they come in various configurations, one or more valves so as to run multiple airstones and to balance the airflow to each stone or ornament. You should not however just use the valve to limit airflow, as this damages the pump eventually. You can just let one of two valves bleed off a little air; however make sure another check valve is in the line from the tank to the valves or else you risk water coming out of that valve if it's lower than the tank water level.....You may want a smaller air pump or an adjustable one instead.

- Q: I see a valve that says FNW on it with ( on, off ) but I'm not sure it's the main valve to the water supply. It does go to the water heater so I'm guessing that it's it. Does anyone know anything about the main water supply valve and how to find it?

- Main Water Supply Valve

- Q: Anyone know what causes a heart valve to leak? I had surgery to repair mine (mitral) a few months ago, and now I have a very mild leak.

- I would say that it would be because of thin tissue.

- Q: I just want to ask do i turn clockwise or counterclockwise in the pipe main shutoff valve to turn on the water supply?

- You turn the valve counterclockwise to open or turn on the water. You would turn it clockwise to shut the water off. Think of it as you would as if you were turning a screw. Right is tight. Be sure you open the valve all the way so the packing in the valve is tight, some valves leak a little, especially old ones, if the valve is only opened partially.It pays to work a valve occasionally to keep it supple, otherwise the packing or rubber washers dry out and start to leak. When you are operating a ball valve, one with a flat handle that only turns 1/4 turn or 90 degrees, when the handle is going in the direction of the pipe, the water is on. When the handle is going across the pipe, the water is off.

- Q: like they say on 4 strokes you gotta go get valve jobs, and they cost bout 300 they say? well what does the mechanic do? can it be done at home and your just adjusting them?

- Take the head to a machine shop you have to grind the valves or replace then,Same with the seats Then replace the guides and adjust the valves Not a driveway Job

- Q: i have been told that a bad EGR valve (exhaust gas recirculation valve) could cause a car to buck or hesitate in mid range speed at low rpms, thats what my car is doing. i work at autozone and i used our code reader and there was a code that stated EGR flow malfunction anyone else have this problem ever? please help me! i dont wanna spend the $120 if i dont need to!

- i had one go bad on my 95 saturn, it sometimes ran rough at a steady speed and stalled at stoplights

- Q: My third valve won't move at all. I haven't played my trumpet in a while and I tried to oil it to get it to unstick but it still won't move at all. People say to screw it off but I can only unscrew the little cap at the bottom of the valve where you push in, not the white button at the top. Help please! Thank you so much! =]

- on the top of the valve there is the screw that you turn to open the valve to oil it. if this screw wont turn gently tap the edges of it with the rim of your mouthpiece, and make sure that you get the entire screw cap. if this doesn't loosen it enough to remove the cap, then repeat while hitting it at an angle in the direction that it needs to turn. if this doesn't work take off the bottom cap and drip valve oil up though the bottom to drip up to the top cap and continue with the tapping process. if it still wont move, you need to take it to a shop. once the upper cap is loose, the valve still wont move, this is when you take off the bottom valve cap (if you haven't already) and fully remove a different valve that has already been oiled and push it up through the bottom of the stuck valve, this might be hard to do, and you might need to put in a lot of valve oil into the bottom to get it to move. once this valve is removed, thoroughly clean the valve casing and the valve itself, and oil both before replacing the valve. Hope this helps.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 100 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords