API Cast Steel Check Valve 400 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

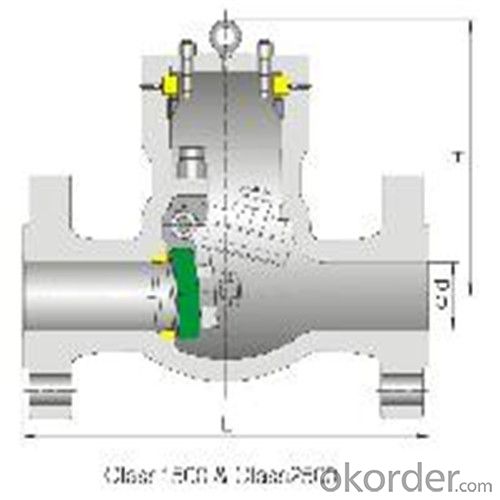

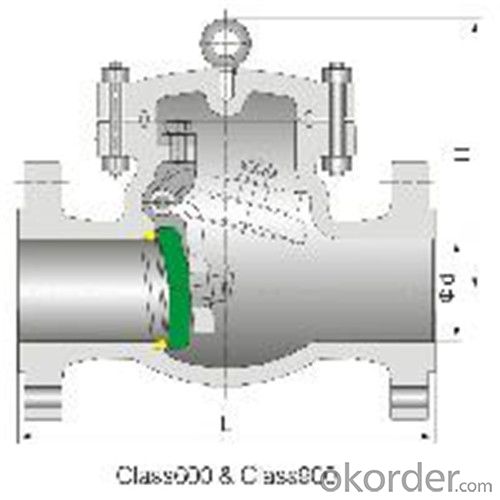

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check="" valves="" and="" welded="" on="" seat="" can="" be="" also="" optional="" if="" being="" requested="" by="" the="" customer.welded="" is="" used="" for="" nps="">12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I accidentally pushed the pressure release valve on my hot water heater last night. It ran for a while, and did not stop. I turned the water off, the valve on the cold water piper above the water heater, and it stopped running. Will this stop running at some point? The overflow tray fills too quickly for me to drain it. When I turn the water back on it starts pouring out again. HELP!!!

- After long periods of inactivity, mineral deposits will form on the pressure side of the valve. When you pushed the valve some of the deposits likely lodged in the valve preventing it from closing all of the way. The good news is that you need not replace your water heater. The bad news is you will likely need a new valve. It is important to replace the valve in these situations because the same mineral deposits that prevent it from closing now can also prevent it from opening when it is needed to relieve excess pressure.

- Q: So i finaly got my check valve and my airstone. The airstone is actually a flat round airstone and is 5 inches in diameter to be in my 10gallon. Is it to big? though i have a tetra whisper air pump for 10-30g.And how do i place the check valve? Do i put it closer to the tank or closer to the pump? (just to make sure since i heard so many different ways people put it). Or does it even matter?And lastly, do i put the OUT side of the check valve facing towards the tank or the pump?Thanks! after this im ready to install it!

- The airstone is not too big, unless it causes the water to bubble right out of the tank. Then you will need a valve to divert the excess air to an unused air line. If the airline is already cut, just put the check valve wherever the airline ends. If it's not cut you can put it anywhere. The arrow on the check valve should point toward the aquarium. If it says IN and OUT, then the OUT is on the aquarium side. If you want to test it to be sure, blow in one end of the valve. You can't blow air into the side that connects to the aquarium. Be sure there is a drip loop in the air pump electrical cord. If water were to somehow get in the air pump or drip on it, water might follow down the outside of the electrical cord and go into the the wall outlet. To make sure that doesn't happen be sure the cord is looped down lower than the outlet and then loops back up before it's plugged in. Get a second airstone any time in the next few weeks. About once a month, trade airstones, putting the recently used one into a jar with white vinegar. A week or so of soaking will unclog the airstone so that it can be used again several times before needing to be discarded. If you do have excess air, I find that running a piece of airline tubing to a spot away from sight and putting a short piece of pipe cleaner in the far end will muffle the hissing sound of the excess air.

- Q: I have a 3406b motor. It has blow by. This happened when I hired a mechenic to do a top end. I belive that he did not ajust the valves correctly or something happen to the motor. I want to gap the valves to see if this helps out. How would I go on doing this.

- try using this link here to help you out. Dont know if you have engine brake or not. but u should be able to still adjust the valves correctly if you follow along with the process.

- Q: I would like to know about the signal pneumatic valves are drivesn (PWM,PCM?) and about their bandwidth and bit rate. Where can i find info?Thanx!!

- Norgren okorder . You will be able to use the valve island configurator, view and download 2D and 3D CAD drawings and receive a list price for complete valve islands. The VM10 is suitable for packaging and textile machinery, electronics manufacturing and many additional applications.

- Q: I need a ball valve that when you shut it off it sends a signal to a light that indicates that it is off.

- Shouldn't be a problem. all that's needed is a valve with elect contacts on valve stem. should be able to get one with two sets of contacts for on and off...

- Q: Hi, I was wondering if it takes a minute or two for the water to actually turn on after turning the valve? I've turned it as far as I can counter-clockwise but there's still no water. Is there something else that needs to be done to get the water back?

- It might take a few seconds (not minutes) to get water to a faucet in the house if your house valve has a drain back feature (house water flows backward to empty the pipes so they don't freeze in winter if you leave (for Arizona or Florida!) and turn the water off.) I turned my water off this way once and called the water company in a panic fearing I had broken a pipe when water started bubbling up through the ground. { Hey, it's funny now. } [Was advised to only use main shutoff at the road in the future.] My house valve under the front water faucet is seen by a 1/2 (or so) square metal stick barely sticking out of the ground. Use vise grips or correct size wrench to grip and turn. Good luck.

- Q: What exactly are valves and cylinders when talking about car engines? Say a car has 3 cylinders or 8 valves for example.

- There are intake valves and exhaust valves. On the intake side, the intake valve opens which lets the fuel/air mixture into the combusion chamber. At some point (measured in degrees of crank rotation) the intake valve closes, the air/fuel mixture is compressed and ignited by the spark plug. Then the spent mixture exits the cylinder when the exhaust valve opens. Valve configuration varies somewhat, but regardless of how many valves there are there will always be at least one intake and one exhaust valve. Some cylinder heads have 2 intake and 2 exhaust valves which is what is described as the 4-valve per cylinder setup. Regarding Car Cylinders, the answerer says Cylinders in a car engine are pretty much like rowers in a boat. But they are not. Rowers always row in synch with each other. Cylinders are made to be out-of-sync for smoother operation. The more cylinders you have, the smoother the engine runs. Compare a 1-cylinder minibike with a 4-cylinder motorcycle (both air-cooled), or a 4-cylinder to an eight... big difference in smoothness.

- Q: according to my study only indurial gate valves have both rising and non rising stem through handwheel and it seems that it doesnot apply to golbe valve and globe valves are only non rising stem. i wanted to know if this is right

- The valve in the upper left quadrant of the picture on this web page is a rising stem globe valve. This type of globe valve is common in cast steel and forged steel valves like those used in the oil and gas industry. They can be as small as 3/4 up to about 8 sizes.

- Q: I have a rainbird Sprinkler system. One of the zones the sprinklers do not pop up. Someone said maybe the valve is stuck closed from the winter. How do you open and close the valve manually to loosen it back up. and where would this valve be located in the little green junction box near where the zone starts????

- they dont really stick from the winter. i would say if the valve has a problem the diaphram needs replacing on the inside of it. ( all you have to do is find the same kind of valve and take the old parts out of the valve and replace them, the top, and the solenoid with the new valve's parts. they can be anywhere in your yard. ive even found the valve boxes buried under bushes. some installers don't put them in boxes, they just bury the valves. if you know where any of the green boxes are open the lids and see what's inside. sometimes more than one valve will be in a box. turn the solenoid on the valve. ( this will be the peice that the wire are connected to on the valve. dont turn the solenoid too much or it will come out. just a 1/4 to 1/2 a turn or so maybe a little more or less. and when you find the valve that turns on the zone 8 that is not working that is the valve for that section. you may even be able to hear the valve trying to come on when the timer shows it is running. if not, then check for power at the valve. if no power. there is a short, bad connection, or bad module in the timer. if power- replace just the solenoid first. if that doesnt work rebuild the valve. if you have no luck finding the box with zone 8 in it then try a few tips. get a screwdriver and poke around where some other valve boxes are. they may be close together. use a wire locator or hire a professional to locate the valve and show you how to repair it. to manually open and close the valve- open upthe solenoid like i said. or use the bleeder if the valve has one.

- Q: I am looking at buying a 2001 Pontiac Bonneville and the guy said the car's check engine light says it had a problem with the EGR valve and so he bipassed it somehow. He said a EGR valve isn't needed. Is this valve very important or needed? What does it do? Thanks

- I have a 1996 Firebird with the same 3.8L V6 motor. I recently had to have the EGR valve replaced, as well. I am not sure- but I think that the EGR valve has to do with the emissions. It may not pass an emissions test if the EGR valve has been bypassed. If you have to have it replaced, it probably won't be that expensive. Good luck. EDIT: here is an explanation of what an EGR valve is, and what its function is, thank you to this gentleman named Shovelkicker for providing an answer elsewhere in 'answers.' This was not my own post- this mechanic whose name is Shovelkicker wrote this explanation, which was written about one year ago in response to another individual's question regarding what an EGR valve is. (The) EGR valve is the Exhaust Gas Recycling valve. This is for when a motor is cold and needs extra fuel to keep running. Back in the days of chokes you would restrict the air going into the carburator to make the car run richer. With fuel injection cars more fuel is added to the engine to richen the mixture. This richer mixture causes the exhaust to have unburnt hydrocarbons, meaning not good for the environment. The EGR opens and allows some of the exhaust to be added back into the intake to be reburned. Once the engine warms up to operating tempurature the EGR closes. The EGR should be a UFO looking item about the diameter of a big coffee cup. Should be brownish metal, lightly rusted from the heat. A a steel pipe, around 1/2 to 1 inch in diameter, will run from the EGR to the exhaust at the back of the engine. Some EGR valves are on the front of the engine, some at the rear. Most frontwheel drive cars with will be right above the exhaust manifold on the front of the engine.

Send your message to us

API Cast Steel Check Valve 400 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords