API Cast Steel Check Valve 600 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

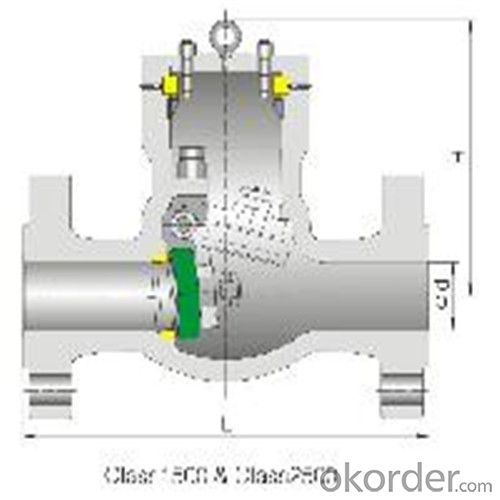

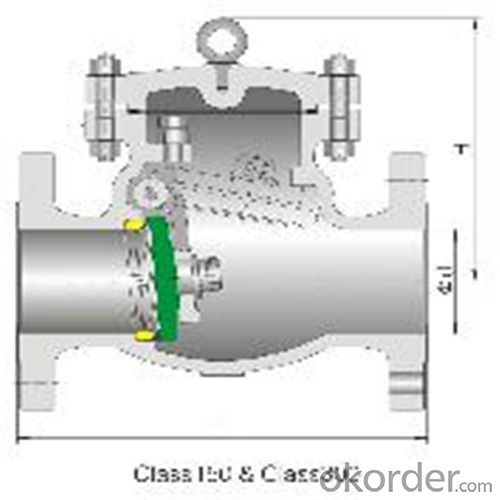

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: i bought thie air connector kit and it has y-valves, suction cups and air control valves, what are the air control valves for?

- air control valves are use for any sort of tubing or air pumps/air stones. air control valves are used to control the amount of oxygen/carbon dioxide allowed into your aquarium from the source. usually air pumps come with a air control valve but if not i suggest using one. also when using any sort of air line tubing connecting from the aquarium and out of the aquarium use a check valve! check valves are so important because it prevent water back flow out of your aquarium and into your cabinet,air pump, and of course you floor/carpet!

- Q: I have a 1993 Jeep Grand Cherokee 5.2L V8 I posted a question on here before and many thanks, What I had was a bent rod well I took off the head and removed all the valve springs and found that where the bent rod was the valve stems are bent too. What else do I need to do? or can I clean the head up make sure no valve holes are bent, replace the rods and valves and be good to go. I want my jeep running again!!! Thanks

- Valve stems don't usually bend unless the valve hits a piston. I am assuming the rod that was bent was a push rod. The 5.2 engine is not an interference engine, so a cam timing problem would not cause the piston to hit the valve. I suppose that if you way over reved the engine a lifter could have pumped up and at a very high RPM the valves may have floated causing one or more to strike a piston. Push rods do bend for a variety of reasons, but to have a bent push rod AND a bent valve stem I would need more information to give you even an educated guess. You have the head off so look at the top of the piston and see if it looks like it was hit by the valves. Take the head to a machinist and have him check it for cracks and damaged guides. Have him check the valve spring tension also.

- Q: Is there a devise to reverse the flow to a cylinder. Not the pump. But a inline flow deverter that would shift the flow from one side of the cylinder to the other at the end of the stroke automatically without a person interjecting.ie it extends fully then the flow reverses retracting it fully. Then the flow reverses, and it extends fully and so on.Preferably, with as little lag as possible during the transition.I want the pump to run constantly(not reversing) and the cylinder to run constantly. Do not worry about the heat generated.Would love something that ran off the main cylinder(like a secondary piston or valve that would opendivert flow at the end of the stroke) through linkage. But, I am open to electronics if need be. Further more want the return to be metered so that the push and pull forces will be the same(metered through a smaller opening to adjust for the rod).Thankyou

- Electrically operated hydraulic changeover valve would be simplest. Then all you need is switches to operate first 1 solenoid, then the other, reversing flow. These could be as simple as microswitches operating latching relays to control the valve. An accumulator should be fitted to reduce hydraulic shock from a sudden direction change.

- Q: Specify eight technical requirements that you would consider important, when deciding upon a particular control valve?

- 1] I assume that by control valve you mean a variable orifice valve, not an on/off valve. 2] An answerer to your other question listed Metallurgy, temperature, pressure and shutoff requirement To which I note that if you need a tight shutoff you should not trust a control valve to do that, but should add an on/off valve in series. Also, metallurgy covers corrosion requirements but not obviously so 3] To which I add: flow rate [or Cv] and pressure drop fail open or fail closed response time signal input [3-15 psi, 4-20 mA, 1-5V, etc] connections [ie, fitting type] packed vs sealed might need to look at hard seat materials and/or replaceable seats, to control erosion reliability, ease of maintenance, availability of spares, timing on that vendor permanence [ie, are they entering bankruptcy ?] Cost

- Q: Can a dirty or faulty EGR valve cause overheating. My 2001 PT Cruiser is overheating but only on very hot days and when the air conditioning is on. Back flushed and pressure tested the radiator, changed the thermometer, fluid was low but doesn't seem to be loosing fluid since refilled. Check engine light came on and indicated poor air flow through the EGR valve. Is it worth replacing prior to pulling the radiator to check that for the problem with overheating? Mechanic I trust doesn't think the EGR can cause overheating.

- No it won't. A attempt to work out if the egr is working outcomes interior the different. while the egr is activated (at idle) the rpm's will drop extensively by way of an over wealthy blend. The overheat is being led to by ability of a few thing else. For the over warmth- verify your coolant point - verify belt tensions - radiator blockage (inner and exterior) - water pump impeller may be loose. may be time for a timing belt besides.

- Q: have a 86 flhtc had new cylinders 10-1 pistons supposed to be 86 cubic inches when i run it up to 90-95 bending valves what can i do to stop bending valves-------HARLEY DAVIDSON

- The other answers are on the right track, but are failing to include the other possibilities. You say you have had the heads done...WHO did the headwork? Were oversized valves installed? What valve springs are you running and were they packed for proper and even seat pressures for the cam lift? Were the valve seats cuts for new valves and if so, was proper valve stem height set? What cam are you running?...What is the TDC lift on that cam? Were ALL clearances checked when the engine was assembled?...Meaning valve-to-valve clearance during valve overlap, not enough clearance and the valves will hit each other...valve-to-piston clearance, this is where the cam's TDC lift specs come into play, if you don't have the proper clearance, the valves will hit the piston........MINIMUM of .060 clearance on both of these checks. What lifters and pushrods are you running?...stock lifters can pump-up at high rpm and lift the valve too much causing it to contact the piston or the other valve. Are you 100% postive you are adjusting the pushrods to their manufacturer's specs...different pushrods manufacturers use different thread pitches that require different adjustment lengths. As you can see, if the engine wasn't PROPERLY built and all clearances checked, you have a MAJOR job ahead of you, this require extensive knowledge and tooling. If you assembled the engine, take it to a reputable performance shop and let them check it out, if a shop did the work, FIND ANOTHER ONE!!! Building performance engines is not easy work and not for the novice.

- Q: 1991 Buick Spirit smokes early for five minutes in morning, from exhaust. Tried every carburator and gas cleanative fluid. Mechanic says Valve job'.

- Probably just the valve stem seals need replacing. NOT a entire 'valve job'. The seals help scrape oil off of valve stem to lower the amount of oil weeping into cylinder when engine is running or turned off. As the rubber ages, it cracks and loses its elasticity and doesn't wipe the stem properly. This is a lot cheaper versus a full 3-angle valve job which requires removal of the heads.. Get a second opinion.

- Q: I heard there are really fine valves, does someone possesses thoughts where to buy these goods? I heard about them on TV. Anybody alive?

- Any plumbing supply shop should have them as well as most home stores, but they are generally for a specific purpose such as at the bottom of a well pick up pipe. Basically a check valve to prevent water from draining back to the well when the pump is off, thus eliminating the need to prime the pump for every on cycle. Al

- Q: I am making a vacuum chamber and need to suck the air out by a tube. What valve do I use? Pin valve, ball, or ? What are they typically called? Compression valves? What if they are designed for water?

- Any valve rated WOG (water, oil, gas) is OK for vacuum. Maximum vacuum pressure differential is atmospheric pressure (14.7psi, 101.3kPa, 1 bar). For convenience, you might use a barbed valve which is sized for tubing (See Yahoo! Images: barbed conical gas valve). Any plumbing and heating supply, or commercial cooking equipment supply will have a variety of miniature bronze gas valves to choose from.

- Q: emission control valve toyota camry

- and the question is ?????????

Send your message to us

API Cast Steel Check Valve 600 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords