API Cast Steel Check Valve 65 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

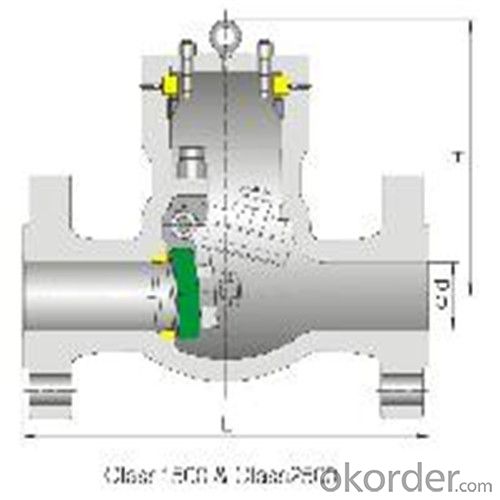

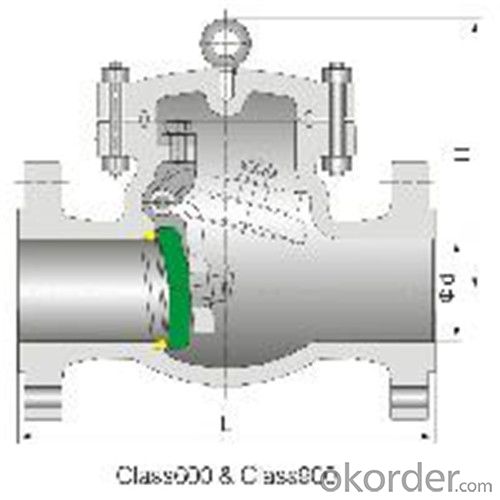

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: my check engine light just came on and i have some oil on the block of my engine, a friend told me that the valve cover gasket needs resealed. could that be why my check engine light is on?

- I assume you checked the oil level. You can go to Auto Zone and have engine codes checked for free to see if you have a problem. I can't see how a leaky valve cover would cause the check engine light to come on unless it fouled some sensor but then again I'm no mechanic.

- Q: IT USUALLY TAKES 2 SECONDS TO START THE MOTOR. NOW, IT TAKES OVER 40 SECONDS AT 7 AM. IT ALMOST KILL THE BATTERY. IF YOU PARK FOR 1 HOUR, 2ND START TAKES 10 SECONDS. IS THIS HAPPENING BECAUSE THE VALVES NEEDS ADJUSTING? HOW AND WHAT IS THE EASY WAY OF VALVES TUNE-UP?

- Dear god I wouldn't touch the valves lol. Start with spark plugs. It should have 1-3 plugs. After plugs, check distributor. After that check carburetor. Plugs/dist are common problems with running/starting issues.

- Q: We have an oil steam system. There are Dole valves - 1A on each of the radiators. We bought new ones. They don't seem to be working. They look like a bullet shape with a screw in (on the side of the bullet) to the radiator. On the top of the bullet is a slit with numbers 1-10 on a dial. A picture we saw on the web showed a plastic piece of tubing in the screw part which looks like it goes into the radiator. If we remove the valve, the radiator gets hot with steam coming out of the hole. With the new valve on, the radiator barely gets warm. We're in Piscataway, NJ 08854. H-E-L-P.

- Seems to me that a steam valve would need to hold a lot more pressure than a hot water valve. Steam is a high pressure gas and water is a liquid irregardless how hot it is (below boiling point) I am not a qualified plumber or boiler tech but personally I wouldn't use a steam valve for water or vise versa.

- Q: I recently broke the valve cap on my tuba and i was wondering if any of you guys knew where to buy a new one or how much it would be.

- you okorder has alot of things but i don't know if they sell separate pieces. Best thing to do is to go to your local music store and tell them and let them find you one,

- Q: I need a bit of help. I am trying to find the location of the EGR Valve on a 1992 Chevy Cavalier 2.2L. If anyone can help me out by posting back a picture or diagram that would be great. I found all the text directions, but did not find that to be helpful.Thanks,

- Ok here we go First raise the hood the engine sits side ways. now on the Passenger side of the Engine compartment is the engine. (i'm serious here) the end with the belt and the pulleys wil /and is Called the front even thou it sits sideways. now the thing on top of the engine is called a valve cover start looking from the front and follow it to the back (that's toward the Drivers side) when you get to the end of the valve cover look down you will see a Valve about 2 inches below the valve cover it has a black Vacuam line that runs to it this is the EGR valve. now Why in the world do you want to make it open on a 1992 Cavalier. most of the time we replaced them because they stuck open and caused idle problems. if your trying to just keep the light out Good luck

- Q: Is there a product that can fit over a foot valve to give it further protection in muddy water? I am looking for something for forest firefighting in mind. Something like a screen box something else that can give it further protection. It would be nice if it was small, and compact. Pictures would definitely be an asset. Thanks to everyone that answers. Greatly appreciated.

- most foot valves i have bought come with a strainer attached perhaps you should look for that type. if your valve has a strainer you may consider making a further coarse strainer out of a ball of chicken wire and place this over the foot valve assembly(thats what i do for the cold water supply to my house) don't compress the chicken wire very small as it will block up i tie the wire filter on with galvanized wire then i can easily replace it if necessary ps i tried stainless steel pot scourers but they were to fine and blocked easily

- Q: 1st valve: this valve used to never cause me trouble at all. THen, suddenly it would stick at the end of the press. I took it home, washed it, cleaned out the casing with the casing brush, cleaned out the holes with a mouthpiece brush, and wiped it clean. Then, i put a bit of oil and it worked fine. Then next morning, i took it out for a second and found it was sticking again. It worked fine afterthat, but why would a valve to that?2nd: this valve is very troublesome. It's sticky for no reason. i did the same thing as the first, but it stayed stuck3rd. Weird valve. One day, i dropped my trumpet (not like down the stairs or anything, just while sitting) and this valve just messed up. What happened, was that when the valve was screwed in all the way, it would be stuck. however, when i unscrewed halfwayor a little less it worked amazingly well. Can a slightly unscrewed valve affect your playing (aside from the clicking noise). Can a valve get dented, causing this?

- I think the reason why your valves are sticking is because they are building up sludge from being oiled too much, and yes, that does happen frequently. Remove the valves carefully, wipe them off thoroughly with a clean cloth, replace them correctly, and lightly oil them. Then try pushing the valves a bit before playing.

- Q: First off I'm a girl. :) My 2.0 non turbo engine has a bent valve. I have been asked to pick up the valve. But I need to know if its for the intake or the exhaust. I know the guy how is going to fix it said he will have to sand down the cylender that it goes in it. The car sounds like it knocking when driving or sitting still. The guy who is going to fix it is at work right now and I'm suppose to order this part right now. Is it an intake or an exhaust valve?

- no way to tell ...and he doesn't sand down the valve ...it's called seating or lapping. and it's not done to the cylinder... knocking could aslo be a hung lifter.

- Q: hi i just found out i have micro valve i and have allmost 30 years with willam sydrome any doctors know more what can happen what dose walking or others got to do with the valve will i stand for a longtime walk jump will one side get weeker then the other what about my hands and eyes my knees what will happend over the years when i get older ?

- I think you mean mitral valve prolapse. I have this. When I was younger I had a heart murmur and did several testing and nothing else became of it. Until recently when I was working out, I had pain in chest that didn't quite go away and went to the dr. and did some testing and diagnosed with MVP. Do not drink decaffeinated drinks b/c it will increase your heart palpitations. You can also be prescribe a medication to help with your palpitation. It's a beta blocker medication. It helps with your heart palpitations, but you should definitely go see another dr. if the dr. you're seeing is not very helpful or see a cardiologist. I was told to just go about doing normal activities.

- Q: i got a filler neck for my dodge dakota and was wondering how to put it on. can anyone send me a link or help me. and also what does my EGR valve look like and i cant seem to find a new one not even at the dealer. i was told to clean it how do i do this. can someone send me a link or pic what it look like. thanks

- The VECI decal map under your hodd will show you EXACTLY where your EGR valve is. You may need a magnifying glass. The valve can be removed and cleaned with Gum-out or foaming cleaner (amsoil). When you are done, re-install the valve. While you are getting ambitious, clean your throttle body and plate, and the IDLE AIR CONTROL VALVE. A dirty IAC is the most prominant reason for the EGR valve to clog up. Running Gum-out through your intake system will clean out your O2 sensors, as well. Good luck!!

Send your message to us

API Cast Steel Check Valve 65 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords