API Cast Steel Check Valve 150 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

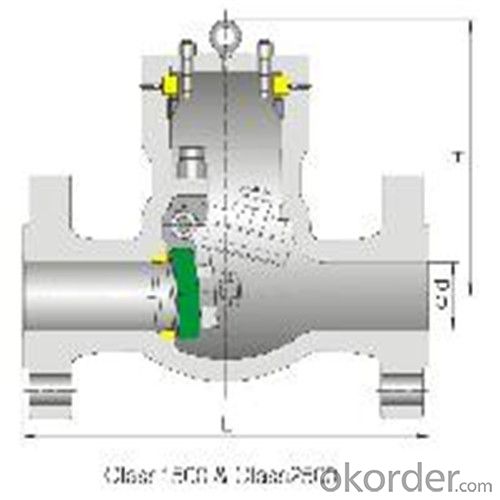

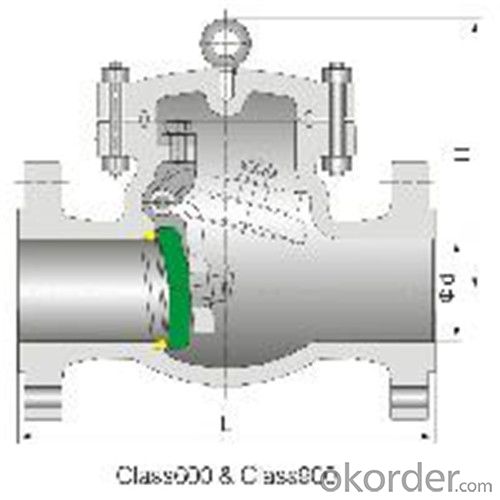

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Between these two Blow off valves around the same price, what would be the best choice for a pt cruiser.

- The Mopar Performance blow off valve is really going to be your best bet if the two are roughly the same price. The reason I say that is because the Mopar unit is designed to fit onto that car, therefore it is engineered to release excess pressure at a safe level for that engine. The Greddy unit is also going to typically require modification to make it fit and function properly. Unfortunately, what they don't tell you about universal units is the reason they are universal is because they don't fit anything until you make them to fit, you just have enough material and hardware to get creative with it. If you are looking to extensively modify your engine, then it may benefit you to go with the universal unit and just wait until you have your piping cut exactly the way you want it, this may give you better location or clearance using the aftermarket unit, but otherwise like I said, I would go with the factory performance BOV. If you have any further questions about your cruiser, please feel free to email me, I have had a cruiser for a couple of years now and have also done lots of customizing to cruisers for friends.

- Q: I just dropped my 3rd valve slide from my trumpet on the ground. It fell with the curved end first. I can't see any dents and it doesn't look bent, but I oiled it and everything and it's really hard to move. Could it be bent? How can I fix it?

- Be sure that it is aligned correctly when you place it back in the valve casing. When you are putting it back in, it has to turn until you hear a click, indicating that the valve guide has fallen in the right space. This aligns the valve with all the ports. (The valve guide is a small plastic piece located under the valve spring. This valve guide must snap into a little notch inside the casing. When it does, the valve will be perfectly aligned. You will know when the valve guide is in the right place because you will feel and hear a click and the valve will not rotate any longer.) After thorough cleaning, oiling, and correct valve placement, if you still notice it sticking, take it to a repair shop to have it chemically cleaned. They are typically very good and will ensure your trumpet is in proper playing condition.

- Q: I am doing a big project on Valve and it's games. I am currently doing some research on the company and wanted to see if anyone had any interesting facts or information about Valve that may be useful when doing research, thank you. :)

- Google can help

- Q: i believe it's to do something to the valve guide to make it the right clearance n not go straight to the valve seat right? or is valve seat next?

- Once the valve guide is installed, it has to be reamed to fit the valve stem. After it has been reamed to fit the valve stem, the new valve needs to be seated in. (The valve seat should have already been done by this point) This can be done with a machine tool, or it can be ground in by hand with valve grinding compound. Once this is accomplished, the valve is removed, everything is cleaned thoroughly, and the valve is reinstalled with the spring and keeper. Normally you would do all the operations to all the valves at the same time. (That is, you don't grind in one valve, then go back and ream another valve stem. You do all the operations required at one time. So you would install all the valve guides, then ream them all, then grind or face the valve seats, then check the valve contact area, then remove all the valves, clean the head and valves up, and then reasemble into a completed head unit.)

- Q: my dad is going to go under heart valve replacement what are the chances of him surviving he is 58 years old and has copd

- It depends a lot on which valve and why it's being replaced, but unless the COPD is very bad, the average chance that a 58yo man who does not have any other major medical problems will survive single-valve replacement surgery is better than 98% if the surgery is done by an experienced surgeon at a good hospital. The COPD will very likely mean that his post-operative recovery will be prolonged and difficult, but he should do fine.

- Q: I started out playing trombone in middle school, then switched to euphonium as my main instrument. (I still play trombone for marching and jazz band, but I'm a little better at euphonium.) That being said, should I get rotary valve trombone or the one with axial flow? I only have a student trombone right now... And I have a professional Besson euphonium.

- Rotary Valve Trombone

- Q: I need to make a one way valve that would allow water or other fluid one way but if there is too much pressure on the opposite side the valve will close and stop water from flowing backward. Can anyone help?

- You are looking for whats called an RP or back flow device. These may be sold at home depot. However, I know your local plumbing supply house would carry them.

- Q: And' the valve leaks......Can the valve be unscrewed from the tank for replacement? Or can the valve be serviced with a new gasket perhaps?

- Go to the following site and enter the Model of your water heater in the box provided Click on the Magnifying glass. This should give you a list of all the parts for your water heater.

- Q: primary function of a valve position?

- ...to control flow.

- Q: I am a 55-year-old female going in for mitral valve replacement surgery, and I need to decide on which valve to get: bovine or mechanical. If you have any experiences or know anyone who's had either of these types of valves placed in their bodies, please elaborate on the experience. I want to know the pros and cons of each.Thank you.

- I had open heart surgery, repairs to my mitrial and tricuspid valves. On the mitrial valve, an Edwards Lifescience ring was placed to tighten valve and the tricuspid was just tightened. That was five yrs ago. Have more energy and feeling better, still. My surgeon did mention placing a porcine valve but once they got inside my heart, the DRs. choose the lifescience ring. I do take an anticoagulant but for other reasons for over 8 yrs now.

Send your message to us

API Cast Steel Check Valve 150 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords