API Cast Steel Check Valve 750 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

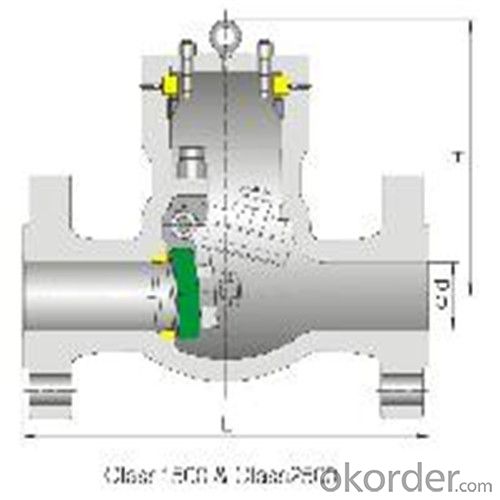

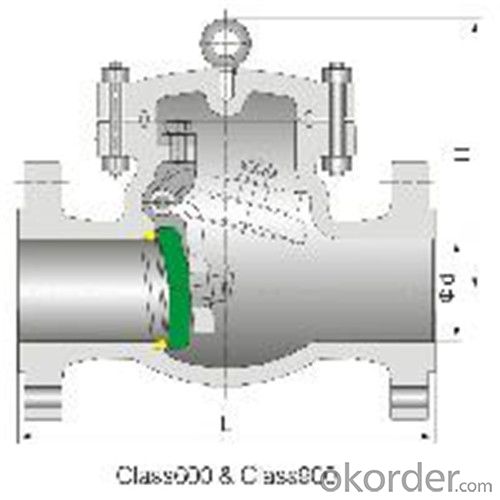

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: What are the names of the main arteries and valves?????????REALLY NEED ANSWERS TODAY!!!!!!!!!!!

- Main arteries: Aorta (oxygenated blood from heart to body), Pulmonary Artery (DEoxygenated blood from heart to lungs). Main Valves: Tricuspid valve (separated right atrium and ventricle to ensure correct flow of blood), Bicuspid Valve( separates left atrium and ventricle), Aortic Valve( ensures blood flow from left ventricle into aorta). hey sorry only saw ur question today:P hope it helps!

- Q: I have a 87 cbr600, consumes oil at a considerable rate. Took the engine out of the frame and disassembled cylinder head, block and pistons and found there is a thick layer of cooked-on oil over all sixteen valves. I figured the oil consumption was due to bad rings, but could it have been the valves?

- Do you remember when and how it smoked? If it smoked when you first started it but for the most part nothing else it would be the valve guide seals. If it smoked all the time it would be the rings. If it smoked during deceleration it would be the intake valves/valve guide. If it smoked during acceleration it would be the exhaust valves/valve guides. Hope this will get you looking in the right dirrection and good luck.

- Q: my check engine light just came on and i have some oil on the block of my engine, a friend told me that the valve cover gasket needs resealed. could that be why my check engine light is on?

- I assume you checked the oil level. You can go to Auto Zone and have engine codes checked for free to see if you have a problem. I can't see how a leaky valve cover would cause the check engine light to come on unless it fouled some sensor but then again I'm no mechanic.

- Q: After shutting off the hot and cold water lines to my washer to remove the unit from my laundry room i noticed a small leak coming from the hot water valve as if the valve is not completely closing. The valves themselves should be roughly 10 years old and were extremely tight when attempting to close them, my question is how big of a job is this to replace the water valve? Is it as simple as turning off the main water to the house and replacing the valve or are these typically soldered on? Currently i just ran the hose for the hot water to the drain line to prevent water from leaking onto the floor so is this something that is a fairly non issue once i hook the lines back up to the washer and turn them back on? Or is this something i should get addressed asap?

- Of course, the best solution is to replace the valve. Valves are either soldered on or attached to the pipe with compression fittings. If the pipe is copper and you see a silver band of metal between the pipe and the valve, that's probably solder. In this case, it would be best to let a plumber replace the valve. Otherwise, if your valve is attached with a compression fitting, you can get a new valve at your local home improvement store in the plumbing section. I recommend getting a 1/4 turn, steel ball valve. These are very simple and reliable valves. When you remove the old valve, be sure to also remove the compression washer and shoulder nut as well. You'll want to use the new ones that come with your valve. I also recommend using Teflon tape to wrap the threads of your new valve, at least two times in the direction of nut tightening. This will reduce the chance of leakage through the threads. Tighten the compression washer between the valve and the shoulder nut snugly. Make sure the valve is off. Turn the water on and check for leaks. If you see periodic drips, tighten the shoulder nut until the dripping stops. The other cheap and dirty alternative is to get a cap for your existing valve. These are also available in the plumbing section of your home improvement store. They run about $2-3, I believe, and are threaded onto the faucet where your hose attaches. That will keep your leaking valve from dripping all over the place.

- Q: I was wondering if the pressure relief valve can be vented right under the house or does it have to be ran to the outside of the house. Also is there another method such as a catch pan that I can employ? I live in Washington.

- Most codes state that it must be vented to the outside.Check with your city code enforcer or county office.

- Q: the air valve, how does it propel a paintball in a blowback operated paintball gun how does the size/shape/?? of the valve impact how fast the paintball shoots?

- The majority of blowback paintball guns use a pin valve, which is opened when struck by the hammer. The hammer is held in the back position, with the spring compressed, by a sear. When the trigger is pulled, the hammer is propelled forward by the spring, into the valve. These sorts of markers generally use a “stacked tube” design, in which the valve and hammer is contained in the lower tube, while the bolt, which is connected to the hammer, is in the upper tube. The gas released by the valve is then simultaneously channeled up to the bolt to fire the paintball, and back to push the hammer back into the ****** position (hence the name “blowback”). Poppet valves are usually easy to replace and require little, if any, maintenance. The downside to this design, however, is its high operating pressure, which leads to a larger recoil and arguably less accuracy. The valve is usually designed to accommodate a specific operating pressure. Low pressure valves provide quieter operation and increased gas efficiency when tuned properly. However, excessively low pressure can decrease gas efficiency as dramatically as excessively high pressure. The volume of gas released by the valve directly affects the paintball's velocity. The velocity adjuster alters the pretension on the hammer spring which controls how long the pin valve is held open for, or more correctly how much gas must be released to push it back into the ****** position. EDIT - Sorry but wouldn't even know where to start on designing a valve.

- Q: Do blow off valves serve any purpose besides making the hiss when you shift? how much does one cost?

- Blow-off valves only work on turbocharged or supercharged engines. It is an intake manifold pressure regulator. I've seen people put them on regular engines thinking they would hear that hiss, but there is no where near enough pressure for them to do anything.

- Q: I have a 78 honda hawkii 400 or cb400TII and I need to know what the valve gaping needs to be set to

- Try okorder or usually free down loads.

- Q: Hi guys, my parents had me install a new faucet in their kitchen sink. It works great and everything, but after the install the hot water pressure basically decreased greatly. The cold water pressure is fine, but I believe after I had turned off the hot water at the shutoff valve, something in the valve got messed up and is blocking the water supply.

- Kitchen Sink Pics

- Q: My third valve won't move at all. I haven't played my trumpet in a while and I tried to oil it to get it to unstick but it still won't move at all. People say to screw it off but I can only unscrew the little cap at the bottom of the valve where you push in, not the white button at the top. Help please! Thank you so much! =]

- on the top of the valve there is the screw that you turn to open the valve to oil it. if this screw wont turn gently tap the edges of it with the rim of your mouthpiece, and make sure that you get the entire screw cap. if this doesn't loosen it enough to remove the cap, then repeat while hitting it at an angle in the direction that it needs to turn. if this doesn't work take off the bottom cap and drip valve oil up though the bottom to drip up to the top cap and continue with the tapping process. if it still wont move, you need to take it to a shop. once the upper cap is loose, the valve still wont move, this is when you take off the bottom valve cap (if you haven't already) and fully remove a different valve that has already been oiled and push it up through the bottom of the stuck valve, this might be hard to do, and you might need to put in a lot of valve oil into the bottom to get it to move. once this valve is removed, thoroughly clean the valve casing and the valve itself, and oil both before replacing the valve. Hope this helps.

Send your message to us

API Cast Steel Check Valve 750 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords