API Cast Steel Check Valve 200 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

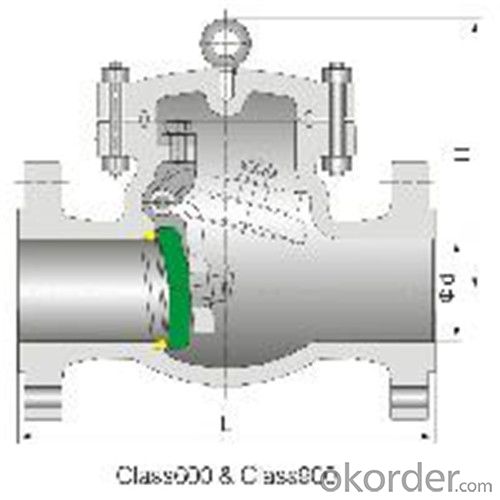

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

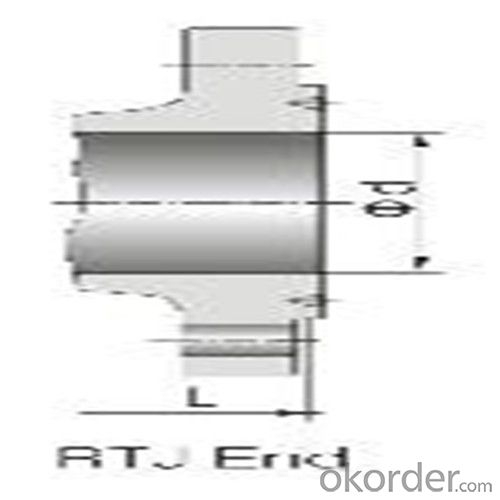

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I have checked this and ensured that the flow control is turned on. I have also found that:1. Valve works in manual mode2. Solenoid is getting electricity and water seems to be flowing in automatic mode but nothing is coming out of the sprinkler.I am not sure what could be broken as manual operation works and solenoid sems to be working. Any ideas?Thanks.

- Toro Irrigation Valves

- Q: There has been brake fluid leaking below where the Master Cylinder was and pinpointed that the leak was at the base where the steel lines and proportional valve intersect(kinda sprays out out like if a seal is bad or someone didn't tighten enough). Any way to fix this or replace? Vehicle is a 1988 Plymouth Reliant (2.2 liter) Auto, no ABS.

- no count number if it incredibly is a proportional valve a 24 volt supply won't supply proportional administration. to boot, controlling an inductive load with a persevering with voltage slows the reaction time.

- Q: my inflatable kayak has a self bailing drain valve. it says to close the valve in lakes and streams to stay completely dry and open it in oceans or mild whitewaters.whats the point of this valve? i WANT water to come in??

- If you're out in rough water, such as in whitewater, water is going to splash up over the sides of the boat. If the valve is closed, then the water that comes in has nowhere to drain. Soon the boat will fill with water and get sluggish and possibly unstable. So you leave the valve open. But the problem with having the valve open is you will have a little bit of water coming up through the valve and into the boat. You won't have a lot of water come in because the inflatable floor of the kayak keeps you somewhat above the level of the water. But on calm water where you won't have water splashing into the kayak, you can close the valve to keep that tiny bit of water out too.

- Q: Is there any treatment available for a leaky heart valve?

- This Patient Guide is written for the loved ones of heart patients who are dealing with the short-term stress that comes with a test, procedure or recent diagnosis of heart disease. It explains why support is so important to a loved one with heart disease. It also offers practical strategies on how to support a loved one while also taking care of yourself.

- Q: We have a 2005 GMC Sierra 1/2 ton truck that has a check engine light on. The dealer checked the code and he told us we need a new Evap Vent Valve and clamp. The cost is over 500.00 with labor being most of the cost. Is this diffcult to change out? Im a very mechanical person. Also he said it would be ok to drive for now but could cause problems down the road. ????like what?My wife is getting ready to take a trip in it, should it be ok for awhile? Dont have 500+ to spend on it now.

- the evap system is one of the main reasons why most cars ses light is on.......we repair lots of these for all car brands every month.....#1 yes it is labor intensive but it is possible to do yourself if u have the proper tools...u would be surprised how many techs in this industry have no understanding of evap systems what they do and how they work...we have not replaced many vent valves,but that could be whats wrong....just for grins buy yourself a real gm gas cap and try before you make any repairs.....7 out of 10 times they fail any tests.....let your wife drive it there will be no issues on her trip///but you have a very nice truck and this issue needs to be repaired....

- Q: people tell me i need to install new valves and valve guides

- Maybe you simply need to re-adjust your valves? Or buy a Lancer.

- Q: Hi, I just got my 20 gallon freshwater aquarium yesterday and set it up today with the filter,water, pump,etc... I bought an AquaCulture 20-60 gallon double outlet air pump and didnt realize it had two valves. I only need to use one though ...what should I do??p.s. The bubbler thing that lets the bubbles out is a rectangle and its long but it isnt working in the middle of it...? would that be because of the double valve?p.p.s. the pump came with two check valves.Thanks, Sarah

- If the pump doesn't come with any method to shut off one of the outlets, you can combine both outlets into one by using some tubing and a T-valve. You can also use an air valve and some tubing on the unneeded outlet to dead-end it, though that method may be a bit more stressful on the pump.

- Q: The hot water in my bathroom is leaking from the faucet. I've shut off the valve below the sink, but it continues to dribble out. Also, there appears to be some rust build-up. Could that account for a failing valve?

- It sounds like your shutoff valve is not working properly. You need to shut off the hot water at the main valve where it comes out of the water heater (this will shut off all hot water in the house); drain the line (there's a little knob on the main shutoff valve you can twist that will allow the water in the pipe to drip out), then replace the shutoff valve. The shutoff valve is probably threaded pipe and can be loosened using two wrenches (hold the pipe with one wrench and twist the nut with the other - you want to conteract the twisting motion on the pipe so the pipe does not weaken and burst, which is why the one wrench needs to hold the pipe). once the valve is removed, clean the pipe threads with a wire brush and cleaning solvent to remove the rust and install the new valve. Be sure to read the manufacturer's directions to see if you need to wrap the threads with teflon tape first. When the valve is replaced, you can turn on the main hot water valve at the water heater; then use the new shutoff valve when you prepare to repair or replace the faucet. I would expect the faucet is leaking due to worn out washers, you can take it apart and tell. I susupect the rust you see is a result of the leak and not the other way around.

- Q: The valve on my radiator has numbers on it to determine the amount of air/steam leaving the heating system. what number should i put it on and how would i determine it

- I would think the easiest way would be to put a thermometer on the radiator (with the bulb in the air flow), turn the heat on to one setting and record the temperatures each half hour for about 4 hours. Then, turn the adjustment to a higher (or lower) number and repeat that. That way, you'd know which way to turn to set it. Of course, the level at which you'd be comfortable would be found by trying different settings. Assuming the adustment is a valve, valves in the USA will open by turning counter-clockwise. Closing is, of course, clockwise. Hope that helps. EDIT: I received your email - I don't mind at all! OK, so you have only one valve for all the radiators. Without knowing anything else, I'd say you just removed the part called the bonnet (the upper half of a valve). It shouldn't matter which number it's set on if it's reinstalled correctly. When a valve is removed, the best way to put back is to open it slightly (turn counterclockwise to a low number), then reinstall the bonnet. Once it's back in, it should work like normal. If that doesn't work, perhaps you can get a plumber or a local handyman to check it. As to the upper ones being airlocked, it really sounds like there is a blockage in the supply line. I am assuming this is steam-heat radiator that is supplied by a boiler-type heating unit?

- Q: 1st valve: this valve used to never cause me trouble at all. THen, suddenly it would stick at the end of the press. I took it home, washed it, cleaned out the casing with the casing brush, cleaned out the holes with a mouthpiece brush, and wiped it clean. Then, i put a bit of oil and it worked fine. Then next morning, i took it out for a second and found it was sticking again. It worked fine afterthat, but why would a valve to that?2nd: this valve is very troublesome. It's sticky for no reason. i did the same thing as the first, but it stayed stuck3rd. Weird valve. One day, i dropped my trumpet (not like down the stairs or anything, just while sitting) and this valve just messed up. What happened, was that when the valve was screwed in all the way, it would be stuck. however, when i unscrewed halfwayor a little less it worked amazingly well. Can a slightly unscrewed valve affect your playing (aside from the clicking noise). Can a valve get dented, causing this?

- I think the reason why your valves are sticking is because they are building up sludge from being oiled too much, and yes, that does happen frequently. Remove the valves carefully, wipe them off thoroughly with a clean cloth, replace them correctly, and lightly oil them. Then try pushing the valves a bit before playing.

Send your message to us

API Cast Steel Check Valve 200 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords