API Cast Steel Check Valve 350 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

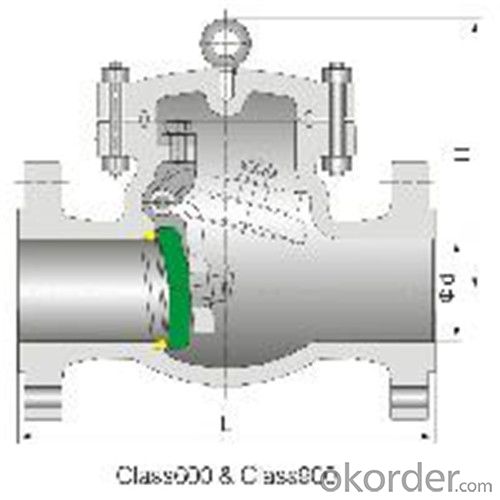

Body and Bonnet Connection

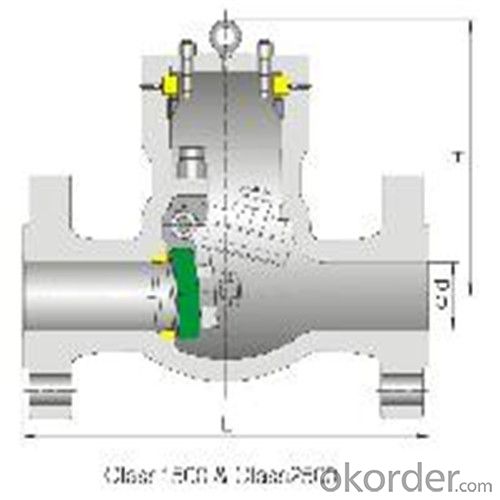

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Anyone know how to stop this from happening? I have gone through 4 since March.

- are you sure its the egr valves going bad or not the egr solenoids causing you to get the code,that will make it appear that an egr has gone bad when it really hasn't,good luck.

- Q: This happens when the sprinklers are ON and goes on for a minute after the sprinklers go off. Should I replace the whole valve or do I need to check the diaphram or solenoid head? In addition to leaking, I have noticed a more potential problem - water hammer. As soon as the sprinkler goes off, I hear this loud banging noise from the pipes underground. Water pressure is fine ~ 50. My guess is air inside the pipes is causing this. Is this because of faulty valve which is leaking?Also, any difference between the valves that are sold in Lowe's and Home Depot to that of commercial valve? My lawn guy says commercial valves last a long time.

- I have been given the equivalent line from our water application whilst the stress valve broke and blew up our water softener it rather is the 1st element on the line from their tension regulator. luckily, it has a life-time insurance yet their plumber instructed me that it extremely was once the accountability city on the grounds that of the stress regulator which they admitted to being at fault whilst they replaced it.

- Q: Does a diverter valve even make a sound at all?

- No. The only time a diverter valve makes a sound like a blow off valve is when it is torn. When this happens you will also notice a loss of power.

- Q: where can i get my Idle air control valve cleaned on a 84 celica supra

- There should be a VECI map under your hood that shows you where this valve is located. In a pinch, find a Haynes manual or a Robert Bentley manual that has pictures in it. If you can find the valve, you can clean it yourself with a can of spray Gum-out. While you're at it, clean the throttle body and PCV valve, too. Hopefully, you have had the good sense to have used only genuine Toyota coolant in this car, since Toyota heads require a special coolant formulation to prevent aluminum deterioration. More older Japanese engines are ruined with improper coolant than I can write about here. Sensor damage is caused as well! You might take your car to the Toyota dealer and ask them to clean out the valve for you. Since this is only a 2 minute job, they just might do it for free. If they do, at least offer to tip the technician under the table. Be sure to power wash your entire engine bay before you take the car in. They will LOVE you for this!!!

- Q: i believe it's to do something to the valve guide to make it the right clearance n not go straight to the valve seat right? or is valve seat next?

- Once the valve guide is installed, it has to be reamed to fit the valve stem. After it has been reamed to fit the valve stem, the new valve needs to be seated in. (The valve seat should have already been done by this point) This can be done with a machine tool, or it can be ground in by hand with valve grinding compound. Once this is accomplished, the valve is removed, everything is cleaned thoroughly, and the valve is reinstalled with the spring and keeper. Normally you would do all the operations to all the valves at the same time. (That is, you don't grind in one valve, then go back and ream another valve stem. You do all the operations required at one time. So you would install all the valve guides, then ream them all, then grind or face the valve seats, then check the valve contact area, then remove all the valves, clean the head and valves up, and then reasemble into a completed head unit.)

- Q: my dad is going to go under heart valve replacement what are the chances of him surviving he is 58 years old and has copd

- It depends a lot on which valve and why it's being replaced, but unless the COPD is very bad, the average chance that a 58yo man who does not have any other major medical problems will survive single-valve replacement surgery is better than 98% if the surgery is done by an experienced surgeon at a good hospital. The COPD will very likely mean that his post-operative recovery will be prolonged and difficult, but he should do fine.

- Q: do I need a new water heater or can this ne be fixed?

- It can be Fixed. Try as Follows 1) tighten it up 2) Put some Silicone around it 3) Buy a new one a replace it. Make sure that you cut the water OFF before you Change anything out. Pop Off Valves are Not Expensive and are Very Easy to Change out. You need a 10 or 12 inch Pipe Wrench and some Pipe Dope. That is all. You unscrew the old one, put Pipe Dope on the Threads of the New one, and Screw the new one in. Takes about Five Minutes and maybe $ 10.00.

- Q: Hi, I'm looking for asymmetrical two way valve needed in pipe line liquid product

- Valve company has been able to fulfill the requirements of its customers according to the highest standards, and always consider the customer satisfaction, so we would be grateful to receive their viewpoints and comments. So we also hope to contact us if they need further information, confirmation on any product. Please note that according to continually work on improving our products, all products materials, specification, dimensions, and etc. listed are subject to change without notice.

- Q: My car (RWD) has vacuum leak and has the code PO171/PO174. I find some engine oil at the bolt well of the valve cover on the bank 2 side. Can the vacuum leak come from the valve cover? What is the main function of the valve cover? Thanks.

- Valves and the cam or rocker arm assemblies on top of the cylinder heads are lubricated by engine oil that is pumped or splashes up from the crankcase. Valve covers just contain the oil and keep dirt out of the engine. Vacuum comes from the intake manifold, and is routed to various locations through small flexible rubber hoses. A vacuum leak is probably from one of those small rubber hoses that has cracked or come loose.

- Q: I have mitral valve prolapse. Just recently Ive been getting chest pains more often * few times a day* and the panic and anxiety have gotten worse. I had a pain last night that lasted about 10 minutes and it was very uncomfortable.I know mitral valve prolapse is a condition that usually not a threat. But can it get worse over time with some people?My doctor already knows I have it but should I go back to have more tests done?Im kinda scared because my symptoms are getting to be more than what they were.Any advice?

- Mitral valve prolapse does not usually cause the painful symptoms usually associated with a heart attack. Depending on the severity it can cause dizziness or fainting on rising from a seated position. If you press on the left carotid artery, reducing blood flow to the brain a mitral valve prolapse condition will not be able to overcome the extra resistance applied to the artery and may cause a blackout. This depends on your exact condition. It can be corrected by surgery with either an artificial or an organic valve replacement. The chest pains may be something else going on with your heart or just caused by anxiety and stress. I believe it would be best if you went back to the cardiologist and had him/her check you out thoroughly. If only to set your mind at ease and relieve some of your anxiety. Take care

Send your message to us

API Cast Steel Check Valve 350 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords