API Cast Steel Check Valve 300 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

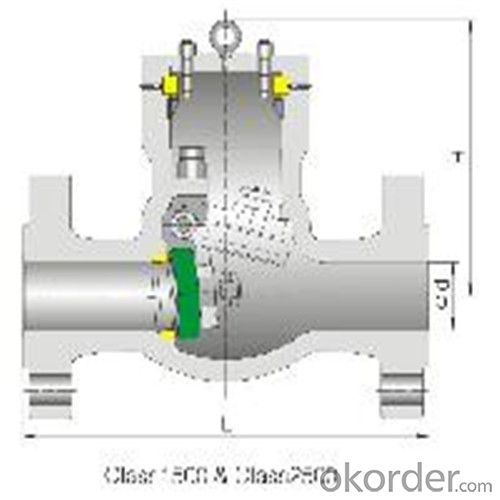

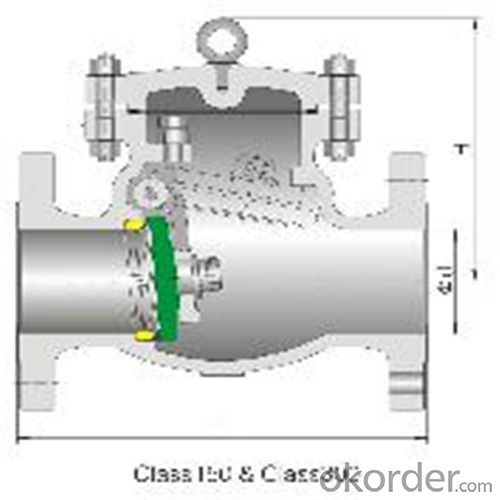

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: please i want theory of MOTORIZED VALVE ? COURSE TITLE : MEASUREMENT AND CONTROL EXP. TITLE : CALIBRATION AND CHARACTERISTICS OF MOTORIZED VALVE

- Limitorque Co. has been a leader in the valve motorization field for decades. Here (below) is one of several web sites where you can find their conventional and modern control techiques.

- Q: What are the types of control valves used in the oil industry and how are they applied.

- There are other manual control valves and on/off automatic valves that are used a various places for remote or emergency control. These can be globe, gate, ball, plug or butterfly valves. They can be actuated by pneumatics, hydraulics or electric power.

- Q: Situation: The males in my family have mitral valve prolapse, while I do not.If anyone could answer some of the following questions, it would be amazing! Thank you so much!1. Is this an X or Y chromosome disease? (I thought since it was just guys, it'd b Y)2. If so (or not), is there any reason why I don't have it?Thanks again! (:

- Dear Madam, I am a cardiologist sending this article for you. Hope it helps you. Mitral valve prolapse, sometimes called MVP, is a common heart valve disorder. The mitral valve is between the left atrium and the left ventricle of the heart. It has two leaflets (flaps) that control the blood flow. MVP occurs when one or both of the leaflets are enlarged or have extra tissue. MVP is usually harmless. However, major complications can occur, including a blood clot in the brain and an infection called infective endocarditis involving the mitral valve as well as other valves. MVP appears twice as often in women as in men. It is most commonly a hereditary disorder. Some people with MVP have no symptoms. However, most patients experience a rapid or irregular heartbeat, shortness of breath, light-headedness, and chronic fatigue. Many patients also suffer from migraines, eating and sleeping disorders, an overactive or inflamed thyroid gland, diarrhea, and cold hands and feet. Emotional stress often magnifies the symptoms. Doctors generally prescribe regular exams and aerobic exercise for people who have MVP. Patients also are advised to restrict their intake or use of high-carbohydrate foods, caffeine, and decongestants. Some patients may need beta-blockers and specific antiarrhythmic medication. More severe cases may require surgery to repair or replace the valve or to insert an electronic regulator, such as a pacemaker or defibrillator.

- Q: I have a 2000 Ford Explorer sport(2wd). I live in the Fort worth,Tx area. What would be a resonable price to have this valve changed out with a new one(valve labor)?

- Valve is about $100 at dealer, $40 at Autozone, give or take, and it should take about 30 minutes, so I would guess about $150 max. I have same problem with 2002, trouble is it's on the transmission, and not that easy for a DIY. As to changing it, mine has caused the check engine light to go on, but has in no way effected the car, so I haven't bothered to change it yet.

- Q: Is it supposed to go on or only in cases when the power goes out??? I bought this pump and the directions are horrible!!! There isn't room for both the air stone and the check valve!! How does this stupid thing work???

- Keep okorder /

- Q: i recently adjusted my valves on my 01 civic with a 1.7 sohc vtec motor and i did it to the specs under the hood and i didnt have them too tight or too loose on the feeler gauge and they are pretty loud are these motors just that noisy? has anyone else adjusted them to something different that works better?

- The dude above is physically powerful, yet incorrect on the fee. you may get an entire swifter equipment for about 1k, a reliable setup will fee a million.5k to 2k with injectors, gasoline pump, a turbine, and an intercooler. 01 are heavy and not super to do mods to, additionally d16 sucks inventory, so which you're able to additionally could desire to yet internals with expenses 900 for the aspects (pistons and rods). entire could be 2k to 3k for an extremely super setup for 250 to 300hp

- Q: I was diagnosed with Mitral Valve prolapse...I'm 21, 5.5 tall and 130lbs, I had a healthy lifestyle...my doctor said that my case isn't really sever..but i'm taking medications to keep it this way...something i cannot ask my doctor about, would intercourse be harmful to me? and how should I deal with it??? is it okay for me to have children in the future? and could my MVP be cured without surgery??

- You can lead a normal health life with MVP. What it is is the valve between the left atria and left ventricle doesn't close fully like it is suppost to and some blood seeps back into the atria when the blood is being pushed out of your heart. MVP is more common then you think. The doc even said to you that your case isn't really severe. MVP cannot be cured without surgery at this time. However you'll be fine. Just keep to your doctor visits as scheduled to keep tabs on it.

- Q: How do you know if you need a new EGR valve or if you just need to clean it?

- Usually it the car runs like crap at idle and beautifully any other time and you can't clean the EGR but cleaning the port in the intake sometimes helps for a check engine light with no running problems But as others said, the EGR is usually monitored with a sensor on or near the valve and the parts houses that do the free scans have a habit of convincing you the part they can sell you will fix it when usually it won't... Take it to a real mechanic shop, let them diag it for you

- Q: i need exhaust valves material dimensinons of any car.

- Most valves are made of forged steel. The dimensions depend on what car. You can get a factory manual for any car. Call a motor shop to order them. Don't try to make them yourself.

- Q: Where do I get a electric valve with a 120 VAC coil

- ASCO okorder is another vendor, though Grainger is good. If your budget is tight you could remove one from a dead dishwasher or washing machine.

Send your message to us

API Cast Steel Check Valve 300 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords