API Cast Steel Check Valve 450 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

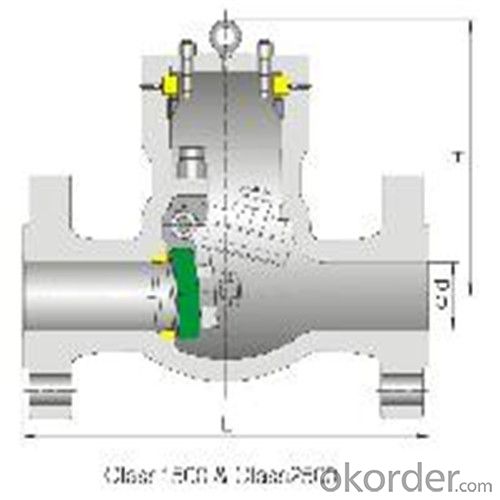

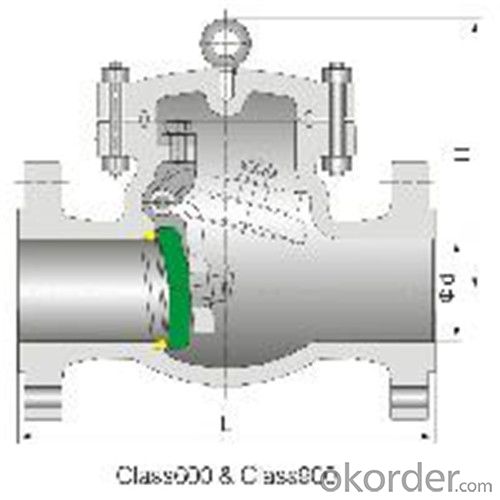

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: The timing belt in my 93 honda accord went out going about 45mph,i then paid someone 150 dollars to put in the new timing belt and it began to shake and he told me that the valves were bent.....i went to a local mechanic and he told me that the valves in honda accords dont bend...is this true?and how much is an average cost to repair the valves and pay someone to do all this?can i do it myself?

- Cooks has it right. Just get a compression test first. If your compression is abnormally low for a car of your age, then you can assume in your case that you have bent valves. Bending them isn't hard - I did it in a '93 Mitsu Eclipse. I missed a gear change and over-revved the engine a little. That's all it took.

- Q: I don't have one single water shutoff valve in my house that will shut anything off completely. It looks fairly easy to repack them, and I have the tools, and there are instructions all over the internet. The question I have for the experienced among you is what packing material do I use? I have heard graphite thread and teflon tape and even joint compound.Is one better than the other? Easier to use?Also, if there are any pitfalls I should know about before I undertake this, please advise.Thanks in advance!

- For stopping leeks use teflon tape to lub your valves use plumbers grease it s good idea to have a tube around not expencive

- Q: Okay so my boyfriend's father is getting a heart valve replacement....he's so nervous he cried last night when he heard it will be in 2 weeks....and he's usually one of those tough guys has anyone or know anyone who has had this type of surgery. They are leaning towards a animal (cow or pig) valve...because with mechanical you have to take blood thinners for the rest of your life...anyways if anyone knows information on this or knows the pro's and cons of the two diff. types of valves please give me info. Thanks

- I worked in ICU for 16 years, 8 of them with open heart patients. My dad also had 3 bypasses and 2 valves replaced at age 80. He will celebrate his 89th birthday in May. My dad had the mechanical because being 80, it should last the rest of his life. He does take blood thinners, as do millions of other people in the world. It's really not that big a deal, and if it prevents strokes and other problems related to clots, people accept that. You got a lot of good information in the Answer before mine, so I won't repeat. Just understand that it's perfectly normal to be petrified and tearful and scared about such a major surgery. Even the big macho men feel that way, and many of them had fears long after they had the valve done. It's normal. Attitude is a very big factor in uneventful recovery, those with more positive attitudes got better more quickly. So after the initial shock wears off, be sure that all of you encourage him, listen to his fears but help him understand it's a new lease on life for him and that all of you will be there to help him get back on his feet as quickly as possible. When I first started nursing, people would be in ICU for 4-5 days, then in the hospital another 2 weeks after having heart surgery. My dad was home in 5 days, and that was 9 years ago! Heart surgery has come a long way, and he has every right to be hopeful about the outcome. Good luck to him and all of you!

- Q: Where can I get a trigger valve like a one you use on a propane tank.

- Its okorder

- Q: The check engine warning light came on in my car, i went to pump gas and try to start but it wouldn't start. I went to the dealership to let them check up, and they said the problem was the purge valve, it leaked. What is a purge valve and what does it do? Is it common for purge valve to go bad?

- Regardless of vehicle make/model,a purge valve is within the fuel system of your vehicle.It's job is to vacuum off fuel vapors from the fuel tank,to be used when the vehicle is running.It works along with your fuel tank cap,to stop vapors/fumes from venting to the atmosphere.On older cars,with carburetors,it work's on vacuum,when the engine is running. On newer cars, say, 1985 and up [approx.] with computers,it works/ is controled by the computer and at least one sensor.

- Q: Also please tell me why globe valves are preffered for Landing valves in wet risers in firefighting and gate valves in dryrisers..

- A okorder /) You are right it is different from a ball valve. I don't know the details of firefighting systems but a gate valve is normally used for shutoff applications and a globe valve for throttling or flow control.

- Q: Hey there in new england wth a blizzard on the way :(. I noticed a few weeks ago that my radiator in my bedroom was always cold. I have lived in this house for 11 years don't know why I am just noticing now. Anyway I discovered that the radiator valve in my room was closed. I shoudl have know it was closed for a reason. I turned it on Wednesday night. everything was fine until this morning. It started leaking thru the celing. my husband tightened it turned it back off and it was fine for a while until it started leaking again! I have since turned the heat off. What can I do now? Did I mention we are bunkered down for a blizzard here? I won't get a plumber out here for days and I fear with the blizzard winds if I keep the heat off the pipes will freeze! Help any suggestions? why didn't it stop leaking after we turned the valve off again??? I am so freaking out right now!

- daniel treasure was correct, but if it is still leaking then it is the packing gland that has worn. make sure that both rad valves are closed, keep hold of the spindle on the leaking rad valve with a appropiate tool so it does not turn, then loosen the packing nut clear of the valve so it rides up the spindle, where the packing nut left the valve you will see the threads where it was attached to, now, get some fine string and a small eletrical screwdriver/ pointed knife, with the string wrap it round the spindle and push into the packing nut theads, but leave some threads showing so you can get the packing gland nut start to bite, tighten the nut up, open the valve slowly and hopefully the string will have compressed enough to stem the leak. good luck.

- Q: I have a 99 Yamaha Warrior 350 and i am needing to take it and get the valves adjusted. I know prices will range from state to state but what would be the average price to take and get them adjusted?? Just the valves not including if they had to change the seals or anything.. Thanks(PS im a girl so put it in simple words!)

- The link below shows what the valves are. The adjustment to them requires loosening #13, and then turning #12 such that the valves #1 2 are within the proper specification. To do this requires disassembly, then measurement and adjustment, and finally reassembly. This can range from 1.5 to 3 hours depending on various reasons. So, estimate 3 x [Labor Rate], whereas [Labor Rate]s vary from shop to shop, and I've seen from $65 to $120.

- Q: I'm going to replace a valve guide and wondering how I should do it.Should I drill into the existing valve guide to the point it's small enough to pinch with some pliers and pull it out?When I put the new one in, should I use a wooden dowel and an air nailer to pound the guide into place?The more info. the better. It's my first time doing this.Thanks!

- Ohhhh man. NO DRILLS. I assume you are referring to an Aluminum Cylinder head. To do it correctly you need a drift punch that has a pilot size of the valve stem, and an outside diameter that is just a few thousands smaller than the guide. Disassemble the head completely, put in Moms oven at the highest setting it will go to ( 5-6 hundred degrees ) Pound old guide out from the combustion camber side. ( have every thing ready to go this FFer will be hot ). Coat new guide with something like STP, put in freezer, carefully align it, then slam it home from the valve train side, don't pussy around, get it in before it attracts the heat of the head, if you stop or it stops you will have to repeat the entire process. If you gall the Aluminum ( say O-**** ) Since you have to hit this thing fairly hard you will need to refinish the inside of the guide with the appropriate reamer. Then refinsh Valve seat ( they never, NEVER line up perfectly )

- Q: I have varicocele and varicose veins. Both conditions are caused by vein valves becoming damaged or defective. My question is, is this a sign of more serious problems?Thank You

- No it seems to be genetic. The valves just aren't doing thier job and allows some blood to flow backwards . They are unslightly.The place varicose veins is deadly serious is the back of your throat. They are caused by scaring of the liver generally by alcholism

Send your message to us

API Cast Steel Check Valve 450 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords