API Cast Steel Check Valve 125 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

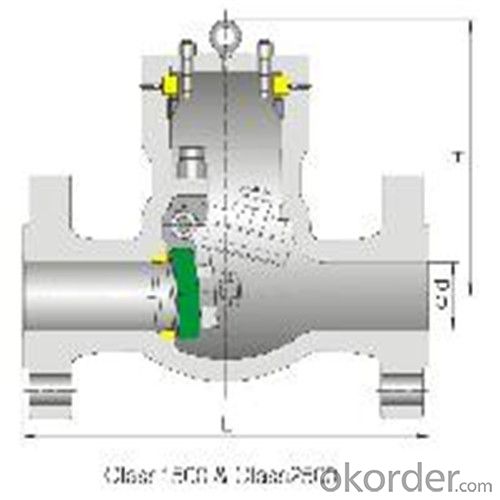

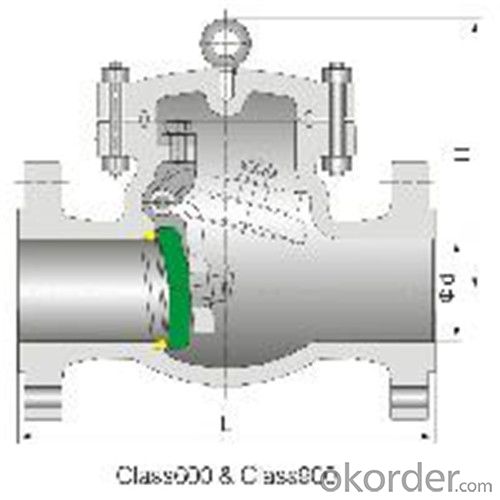

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: anyone know where this switch or whatever you want to call it is located. the car was in accident. so it wont start but cranks. so i wanted to know where the shut off valve is located for the fuel. thanks.

- 2007 does not have a shut off valve. Sounds as if some one has used a non programed key Nissan Imobilizer has detected the aftermarket non programed or key with chip embedded in the key has failed. After 4 attempts the car turns on lock mode and it is tow truck time. Gather up all the keys you have they all have to be reprogramed. And it is a good time to have two complete sets of keys and remotes money allowing of course. Only computerized lock smiths and Nissan dealerships can introduce keys. Is there a red light that looks like a car with a key lighting up when you attempt to start the car?

- Q: Model 28 BS 12.5 HP engine intake valve sticks. Please advise.When under a full load like tall grass, it runs great, but when the load is not as heavy, the intake valve sticks open, spewing gas back through the carb and mis-firing.

- Weird that it runs better under load. Try spraying carb cleaner into the carb while it's running to see if it can remove some carbon build-up or whatever might be causing the lifter to stick. Be careful about how much you spray..too much and the engine will shut off. Spray it until it sputters, let it recover, then spray some more. Check the spark plug. A badly fouled, improperly gapped plug can cause similar problems. Of course clean/replace the air filter.

- Q: A reading from my 2002 ford explorer said insufficient flow from the EGR valve. Would it be possible to clean the valve or fix it or would I need to buy a whole new valve?

- It probably has nothing to do with the actual EGR valve itself, there is a sensor called the PDFE, it monitors the flow of the egr valve, the flow is probably fine and the sensor that monitors it has gone bad, It is a VERY common issue on fords. I would start there. Good luck PS ford has an updated part number for the sensor so get it from the dealer

- Q: i bought thie air connector kit and it has y-valves, suction cups and air control valves, what are the air control valves for?

- The air control valve is for doing exactly what the name implies: controlling the air flow. IT allows you to reduce and regulate the flow of air as needed. They are super handy on multi-tank systems where tanks with shorter air lines get more air and need to be turned down to equalize all the tanks. They are also handy if you are running multiple air stones or air driven decorations off the same pump as it allows you to adjust flow to each device so one it not overpowered and other lacking in flow. The air check valve is the one that prevents water from heading back down the line in a power failure. A air control valve could do this, but you would have to manually turn it to off so the water didn't flow back, where a check valve is automatic and needs no human intervention.

- Q: I was just informed that my 4 year old daughter has been diagnosed with mild mitral valve regurgitation. I have been researching, but only find the information to apply to adults, not children.What general course is taken when dealing with children with this condition and what should I expect? Her pediatrician was treating her symtoms as asthma with breathing treatments, but, I was not comfortable and took her to my family physician, who sent her for the echo, which discovered this.I'm more or less just looking at our options...

- Find yourself, or your daughter, a good cardiologist and follow his advice. I do think that this can be handled with medications in kids as well as adults. Good luck.

- Q: Hey I'm high rite now and i have a checkup for mitro-valve prolapse tomrow, i was wondering if they will take my blood and see THC in me....

- Mitral okorder

- Q: hello!I'm designing a floor cleaner and for a water release system i was thinking of using a ball valve, connected to an actuator,however i'm not fully sure what to look for, and although I can buy the actuator and ball valve together, I'm not sure how to connect it to a motor and battery?If anyone can help my with this I'd really appreciate it!!Thank You!!

- An actuator for a ball valve can use either compressed air or an eectric power source to drive a motor. Air actuated valves can operate very quickly and are a little cheaper but they require a compressed air source and pneumatic controls to operate. An electric operator uses a geared motor to operate the valve and are slower. Electric operators are more expensive but only require power and some switches to operate. See link for hook up details.... The motor is built into the actuator so its just a matter of mating the actuator up with the valve. It would be best to buy a complete unit with the actuator and valve already attached. These will cost at a minimum several hundred dollars. Using a ball valve may not operate fast enough nor give you fine control if your considering using it to control the cleaning fluid applied to the floor. Instead consider using a solenoid valve instead. These are smaller valves and operate very quickly by just adding or removing power. Not to mention these are much cheaper $25 to $100 on average.

- Q: how hard is it to clean the egr valve on my 2002 Chevy Malibu? if you can give step by step or possibly a website/YouTube video link. thanks

- Cleaning it could make it worse then your experiencing now, but if you want to here's the steps. There are two bolts holding the EGR val;ve down. Remove them, and use a can of carb cleaner to clean the carbon out of the two ports that are in the valve. Reinstall with a new gasket and run the car. If the check engine light comes on replace it. I recently got a EGR valve (not recommended but they work) from a local wrecking yard for my folks '99 Venture 3.4 ltr motor, replaced the one on the van because it was throwing the EGR code and it worked fine. No more check engine light.

- Q: How would you change the Heater control valve on a 1997 honda civic hx?its my first car, so i dont know much about cars.

- the heater control valve is in the heater hose under the hood. on the passenger side of the car there will be two heater hoses going into the engine wall. one of them will have a heater valve in the line with a cable attached to it. drain the coolant from the radiator before removing the heater hose or you'll get coolant all over the place and coolant is toxic to animals. after you drain the coolant you can remove the clamps that secure the hose to the valve. have a drain pan under the car as some coolant will still be in the lines. once you remove both clamps you can take the hoses off the valve then disconnect the heater cable. install the cable on the new valve and install in the reverse order. fill the radiator back up will the removed coolant. you'll need to run the engine until the thermostat opens and the coolant level in the radiator drops. then top off the coolant and put the radiator cap on. hope that that helps

- Q: I have a intake valve leakage in both my car and truck. If there some sort of quick fix i could use to stop the leakage for about 1 month.

- what is leaking in to where? assuming that your talking about the intake and exhaust valves,then here goes. if the car and truck are old enough to have a carb on them then if you have gas leaking past the valves then you will need to clean the intake valves, if it's oil leaking into the cylinder then you will need to change out the valve seals-those are located under the valve springs. to do that job you will need an air compressor.if it's compression blowing past the exhaust valves then you will need to pull the heads and have them serviced, same with intake cleaning. sorry no quick fix. either fixed or malfunctioning,those are the choices

Send your message to us

API Cast Steel Check Valve 125 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords