API Cast Steel Check Valve 500 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

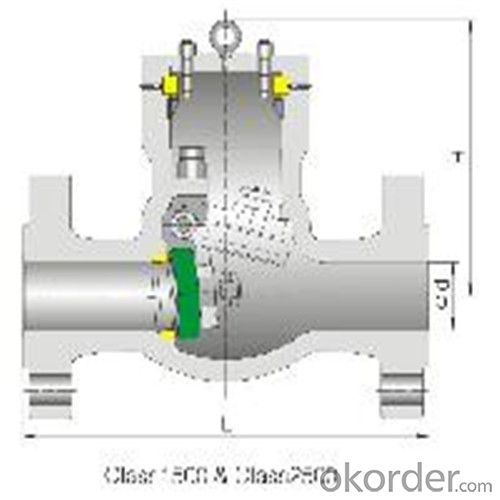

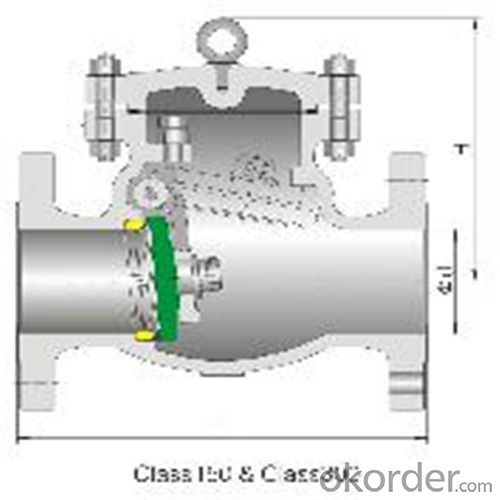

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I know what a valve is, but I would like to know what an actuator does?

- Actuator is acting part of the device, it control the valve open or close, how to open or close, when to open and close and the acting time.

- Q: It's filling up a 5 gallon bucket roughly ever 9-10 hours. It was leaking with an old valve and has been replaced, and after being replaced it didn't stop. The temperature has not been adjusted higher or lower, it's exactly where it was for the year before the leak started. Any ideas?

- Mike, Since you haven't raised the Temperature setting on the heater which could cause this problem, you either got a bad replacement p/t valve OR maybe it was a cheepo. If that's the case, I would replace it with a good brand return the other one after you find the new on works right.

- Q: I have 1998 Husqvarna WR250 2-stroke and the torque valve isnt connected and i am wondering if its worth it4 me to track down the part that ismissing to get it working. does the torque valve increase power much? please help cos im wondering whether i should sell bike and get motocross bike instead.

- The torque valve (it's called the power valve, by most manufacturers) changes the exhaust port timing, depending on the RPMs of the engine. The valve blocks part of the top of the exhaust port. As the engine RPMs increase, the valve lifts up. The distance between the top of the exhaust port's opening and the top of the cylinder is changed. When the piston is moving down on it's power stroke, the opening of the exhaust port is exposed sooner (due to the valve lifting up) and the ignited fuel exits the cylinder faster. This process of changing the exhaust port's timing, creates more explosive power for the engine. So of course if it was hooked up, the engine's performance would increase.

- Q: Also what prevents this from occuring? I have a lab due tomorrow for my biology class this is one of the questions. the answer is no where in my book, and we haven't discussed this in class. im also having a hard time finding the answer online. i would assume it would have something to do with the elasticity of the valves, and i know that when valves are weak sometimes blood can flow back into the artium when the ventricle contracts causing a heart murmur and other problems, but i haven't came across any information that talks about the valve being pushed backwards. if you can help me out that would be awesome! thanks =]

- Valves, because they open when your heart pumps and close, not allowing blood to flow backwards after the pump.

- Q: 1990 5.7l with a .470 lift cam , is there going to be a clearance issue between the valve guide and the valve. Is the rocker going to bottom out on the guides and bust my heads.. If so what should i do.

- I don't think you know what you're asking. Clearance between the valve and the guide is necessary for lube and alignment of the valve. Not too much though or there becomes an oil burning issue. Are you asking if the cam is going to move so far as to make the rocker tip down and hit the top of the guide? If so, do the math.

- Q: I have an old trumpet valve stem that will not screw in the valve cap. I ordered a new one but I'm not sure how to remove the old one and put the new one on without doing anything that would influence the look and playing. HELP!!! Professionals are welcome and others. I don't have any professional technicians near by .Summer band is starting up so I need this FAST.

- I hope you have a Bach trumpet, because each valve stem is specific to a particular maker and even to specific models. So, if you don't have a Bach trumpet it is very likely that the stem won't fit. If you cannot remove the valve stem with your hands you can try soaking the joint with oil and/or warm water and dishwasher detergent. You should give yourself a couple of days to see if you can loosen them up. Do not use tools--no screwdrivers, no pliers, no vices, no strap wrenches--if you don't know what you're doing you stand to damage the very fragile valve. You may need to take it to a tech--remember you're trying to avoid a $100+ dollar bill for repairing a damaged valve.

- Q: I'm installing a shut off valve under my sink. can you tell me all the materials that i need to install it by myself because to hire some body else is very expensive where i live. i need to change the old ones because they are leaking very bad when i want to use the sink.thanks a lot

- It sounds to me like they are leaking from the handle when you turn them on to use your sink? If this is the case all you need to do is shut iff the main take the screw out of the handle and remove handle. Then take off the packing nut and replace the packing material. There are only two types of packing either an O ring or rops packing. Talk to the guy at your local hardware store he can tell you what you have. You may not have to replace the actual shut off valve.

- Q: I jsut got my valve cover replaced on my car what does that do?

- it keeps the oil from flying out and also keeps dirt out of your engine.

- Q: hi i just found out i have micro valve i and have allmost 30 years with willam sydrome any doctors know more what can happen what dose walking or others got to do with the valve will i stand for a longtime walk jump will one side get weeker then the other what about my hands and eyes my knees what will happend over the years when i get older ?

- I have a mitral valve prolapse. Don't know if this is what you meant or not, but it can lie dormant for a long time. I thought I was hvaing a heart attack!!

- Q: My furnace cut out about a year ago. The hvac guy i used told me the gas valve was no good and that the flu was partially blocked. I cleaned out the flu, he replaced the gas valve ($700+) and it worked great for a year. Today the furnace does not fire up. Pilot is working. I cleaned out the flu (there was definitely quite a bit of debris, so that was probably the cause for the shut off) .... The flu is now clear, but when i turn the system back on the thermostat calls for heat, but there is no gas flow to the burner... could the valve have failed that quick, or should i be looking at something else like the CO sensor or something... just looking for some direction before shelling out another 700 bucks... Thanks in advance for any ideas or assistance....

- There are a few possibilities. The valve runs on a low voltage line. The low voltage is provided by a transformer. It it possible the transformer is bad. Be sure the power switch to the furnace is on. (should be on the side of the furnace. Easy way to check is (on the thermostat) turn the fan switch from auto to run. The blower fan should come on. Check that the gas valve is in the ON position.(if you have had to light the pilot it may still be in pilot position.) Another possibility is a clogged gas line. If you have an older home rust can accumulate inside the iron gas lines. Where the gas line attaches to the furnace there should be a drip leg. This is a short length of pipe that points down with a cap on it from the TEE that goes into the furnace. This short piece of pipe is to catch any moisture or rust that comes thru the line. First TURN OFF the gas at the shut off in the pipe it's self. This is a quarter turn valve. When the handle is in line with the pipe the gas is on. When it is opposite the pipe (pointing out to the side) the gas is off. After turning the gas off, remove the cap from the bottom of the drip leg to remove any accumulation.USE PIPE DOPE not teflon tape when putting the cap back on.Turn the gas valve back on and check for leaks.

Send your message to us

API Cast Steel Check Valve 500 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords