Solar Silicon Wafer Price - 6 inch 3bb Monocrystalline Best Solar Cell 18.0%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | China (Mainland) | Brand Name: | xrsolar | Model Number: | ERC-156M-3BB |

Material: | Monocrystalline Silicon | Size: | 6 inch | Number of Cells: | 1 |

Max. Power: | 4.3W | Material:: | monocrystalline Silicon | Size:: | 156mmx156mm or 6 inch |

Max. Power:: | 4.3 watts | efficiency:: | 16%-17.8% | busbar:: | 3 |

Color: | Dark Blue | Voltage:: | 0.508V-0.53V | Thickness:: | 190um±20um |

Packaging & Delivery

Packaging Details: | 100pcs in one box,1000pcs per carton, standard export carton |

Delivery Detail: | 5-7 days after received the payment |

Specifications

3BB Monocrystallin Best Solar Cell Price

1.Size: 6*6 solar cell

2. Efficiency:4.3WMonocrystallin Best Solar Cell Price

6 Inch 3BB Monocrystallin Best Solar Cell Price

Dimension: 156mm x 156mm

Diagonal: 200mm (round chamfers)

Front: Anisotropically texturized surface and dark silicon nitride

anti-reflection coating

1.9mm silver busbars

Back: Full-surface aluminum back-surface field

4.0mm (silver / aluminum) continuous soldering pads

Features

1.High conversion efficiencies resulting in superior power output performance.

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.Low breakage rate

6.Color uniformaity

Packaging & Shipping

1. Item are only shipped after PAYMENT is received.

2. Originally our solar cells are 100 pieces per box, 10 boxes per carton.

2. Please check out your ADDRESS carefully when processing order.

3. Please CONTACT us ASAP if you haven't received the parcel.

Shipping will be made via EMS, DHL, Fedex, UPS , TNT etc

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

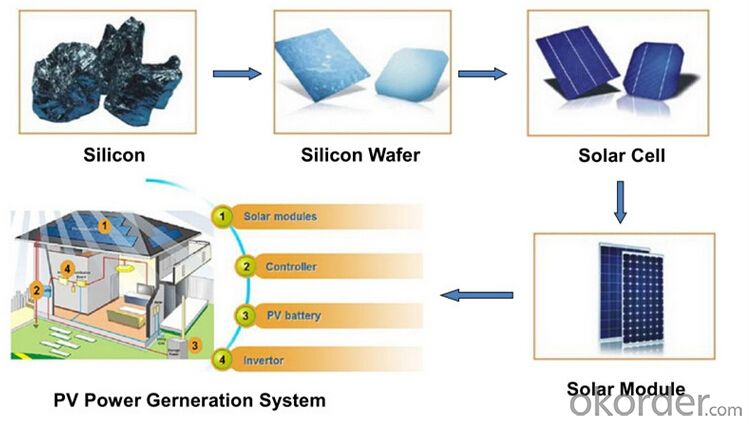

- Q: Can solar silicon wafers be used in solar-powered electric vehicle charging stations?

- Yes, solar silicon wafers can be used in solar-powered electric vehicle charging stations. These wafers, which are made from high-purity silicon, are commonly used in the production of solar cells and panels. By incorporating solar silicon wafers into the design of charging stations, it is possible to harness solar energy and convert it into electricity to charge electric vehicles. This not only promotes renewable energy usage but also reduces the environmental impact of charging electric vehicles.

- Q: What is a good solar wafer testing equipment?

- QCROBOT has been the solar energy as the focus of their products to promote the industry, and has a variety of measurement and control products, for the field of solar energy has launched a variety of measurement and control programs. For example, photovoltaic semiconductor production process control, solar power plant power monitoring system, as well as photovoltaic solar cell volt ampere characteristics test. QCROBOT machine vision system can be used to monitor the shape and size of silicon particles at high temperature. Machine vision can also be used to monitor the quality defects, size measurement, and so on of crystal rods, wafers, panels and components. At present, the QCROBOT vision system and the measurement and control software and hardware platform have been successfully applied to the production and installation process of the solar panel.

- Q: Can solar silicon wafers be used in solar-powered military applications?

- Yes, solar silicon wafers can be used in solar-powered military applications. Solar silicon wafers are a key component in solar panels, which can be utilized to power a variety of military equipment, such as remote surveillance systems, communications equipment, and even portable power sources for soldiers in the field. The use of solar power in military applications offers numerous benefits, including reduced reliance on traditional fuel sources, increased energy efficiency, and enhanced operational sustainability.

- Q: What is the role of a power optimizer in a solar silicon wafer?

- A power optimizer in a solar silicon wafer plays a crucial role in maximizing the energy output from each individual solar panel. It optimizes the performance of the panels by ensuring that each panel operates at its maximum power point, even in cases where panels are affected by shading or mismatched conditions. This helps to increase overall system efficiency, improve energy production, and reduce the impact of factors that may hinder the performance of the solar panels.

- Q: How are solar silicon wafers connected in a solar array?

- Solar silicon wafers are typically connected in a solar array using soldering or conductive adhesive materials. The wafers are electrically interconnected by soldering or attaching metal ribbons or busbars to their contacts, creating a series of parallel connections. This series of interconnected wafers forms a solar cell module, which is then further connected to other modules to create a larger solar array.

- Q: Are there any environmental concerns associated with solar silicon wafers?

- Yes, there are some environmental concerns associated with solar silicon wafers. The primary concern is the energy-intensive manufacturing process of silicon wafers, which requires a significant amount of electricity and raw materials. The production of silicon wafers also generates hazardous waste, including toxic chemicals and greenhouse gas emissions. Additionally, the mining of raw materials like quartz and silicon for the production of wafers can have negative environmental impacts, such as habitat destruction and water pollution. However, it is important to note that compared to other forms of energy generation, solar silicon wafers have relatively minimal environmental impacts over their lifecycle.

- Q: Are all solar silicon wafers the same color?

- No, solar silicon wafers can come in different colors. The color variations can be due to different manufacturing processes or the presence of impurities in the silicon material.

- Q: How do solar silicon wafers perform in high-salt environments?

- Solar silicon wafers generally perform well in high-salt environments due to their durable and corrosion-resistant properties. The silicon material used in solar panels is typically resistant to saltwater, making them suitable for coastal areas or regions with high salt content in the air. However, it is essential to regularly clean and maintain the panels to prevent any buildup of salt deposits, which could potentially reduce their efficiency over time.

- Q: How does the efficiency of a solar silicon wafer change with shade?

- The efficiency of a solar silicon wafer decreases significantly with shade. Shade obstructs the direct sunlight that is necessary for the wafer to generate electricity. When even a small portion of the wafer is shaded, it can cause a drop in overall efficiency. This is because shade reduces the amount of light reaching the wafer's surface, leading to reduced power output. Therefore, minimizing shade and ensuring maximum exposure to sunlight is essential for optimizing the efficiency of a solar silicon wafer.

- Q: How does the efficiency of a solar silicon wafer change with time of day?

- The efficiency of a solar silicon wafer generally increases as the time of day progresses. This is because the intensity of sunlight is highest during the midday period, resulting in optimal conditions for the wafer to convert solar energy into electricity. However, it is worth noting that the efficiency can vary depending on various factors such as cloud cover, temperature, and angle of incidence.

Send your message to us

Solar Silicon Wafer Price - 6 inch 3bb Monocrystalline Best Solar Cell 18.0%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords