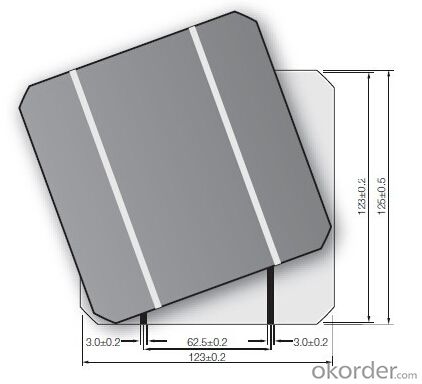

156x156 A Grade B Grade PV Silicon Solar Cell for Solar Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

156x156 A Grade B Grade PV Silicon Solar Cell for Solar Panel

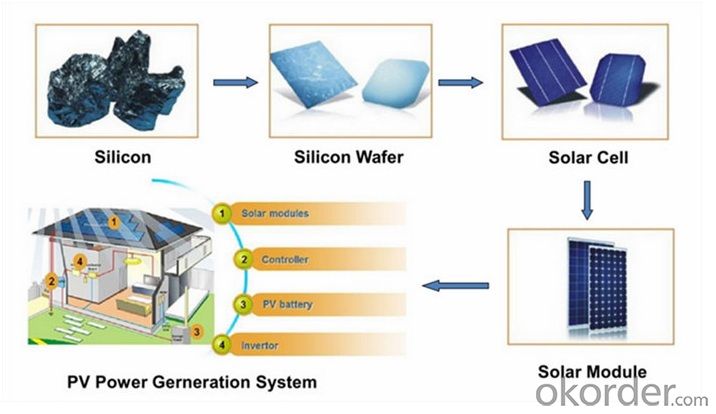

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Main Characteristic

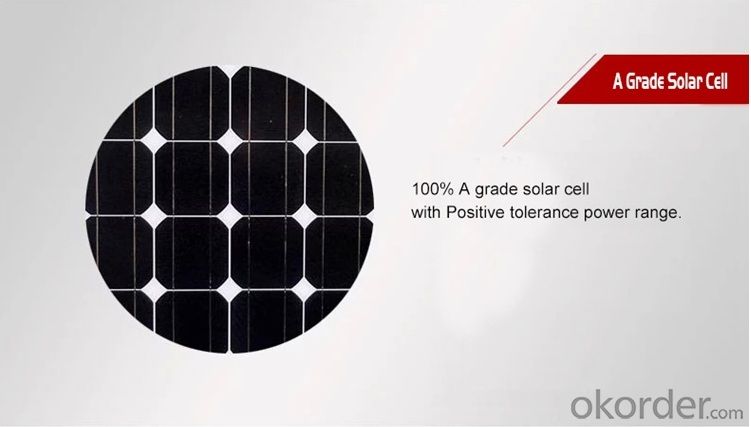

our cells special features

1. High conversion efficiencies resulting in superior power output performance

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.For 156P poly cells with high efficiency in photovoltaic conversion 16.3%-17.5%.

6.Low inverse current, high shunt resistance and high dependability.

7. Our poly cells efficiency include: 17%-18%.

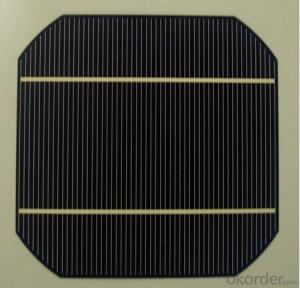

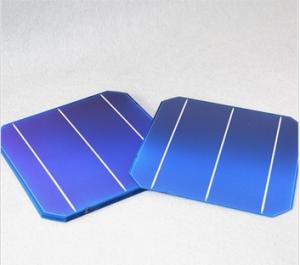

Product Pictures

- Q: How do solar silicon wafers contribute to job creation in the solar industry?

- Solar silicon wafers contribute to job creation in the solar industry by serving as a fundamental component in the production of solar cells and modules. As demand for solar energy continues to rise, the manufacturing of silicon wafers expands, leading to the establishment and growth of solar panel manufacturing plants. This expansion creates job opportunities not only in the production and assembly of solar panels but also in related areas such as research and development, quality control, logistics, and sales. Additionally, the deployment of solar panels stimulates the installation and maintenance sector, further contributing to job creation within the solar industry.

- Q: How does a solar silicon wafer convert sunlight into electricity?

- A solar silicon wafer converts sunlight into electricity through a process called the photovoltaic effect. When sunlight hits the surface of the wafer, it creates an electric field that allows the electrons in the silicon atoms to move freely. These energized electrons are then captured by metal conductors on the wafer, creating a flow of electric current. This generated electrical energy can be used to power various devices and systems.

- Q: How is the purity of a solar silicon wafer measured?

- The purity of a solar silicon wafer is typically measured by evaluating its resistivity. High-purity silicon wafers have lower resistivity levels, indicating fewer impurities present in the material. This measurement is crucial as impurities can negatively impact the efficiency and performance of solar cells.

- Q: What is the purpose of a junction box in a solar silicon wafer?

- The purpose of a junction box in a solar silicon wafer is to provide a secure and protected enclosure for the electrical connections of the solar cells. It helps to connect the individual solar cells together and allows for the efficient transfer of generated electricity from the cells to the external circuitry, such as inverters or batteries. Additionally, the junction box also serves as a safety feature by offering protection against environmental elements and potential electrical hazards.

- Q: How are solar silicon wafers protected from extreme temperatures?

- Solar silicon wafers are protected from extreme temperatures through the use of various techniques such as thermal annealing, passivation layers, and encapsulation with protective materials. These measures help to ensure that the wafers can withstand and operate efficiently under both high and low temperature conditions.

- Q: How thick are solar silicon wafers?

- Solar silicon wafers typically have a thickness of around 200 to 300 micrometers (0.2 to 0.3 millimeters).

- Q: How is a junction box sealant applied to a solar silicon wafer?

- A junction box sealant is typically applied to a solar silicon wafer by dispensing a precise amount of the sealant material onto the designated area of the junction box. The sealant is then spread evenly and smoothly using a tool or applicator. The application process ensures that the sealant effectively protects the junction box from moisture and other environmental factors, ensuring the durability and longevity of the solar wafer.

- Q: Can solar silicon wafers be used in solar-powered electric vehicles?

- Yes, solar silicon wafers can be used in solar-powered electric vehicles. These wafers are commonly used in the production of solar cells, which convert sunlight into electricity. By integrating solar silicon wafers into the design of electric vehicles, it is possible to harness solar energy and supplement the vehicle's battery power, increasing its overall efficiency and reducing reliance on traditional charging methods.

- Q: How are solar silicon wafers protected from hailstorms?

- Solar silicon wafers are typically protected from hailstorms through the use of tempered glass or specialized coatings on the surface of the solar panels. These protective layers are designed to provide an extra layer of durability and resistance to hail impact, minimizing potential damage to the solar cells and ensuring the long-term efficiency of the panels.

- Q: What is the maximum temperature that a solar silicon wafer can withstand?

- The maximum temperature that a solar silicon wafer can withstand is typically around 200-300 degrees Celsius.

Send your message to us

156x156 A Grade B Grade PV Silicon Solar Cell for Solar Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords