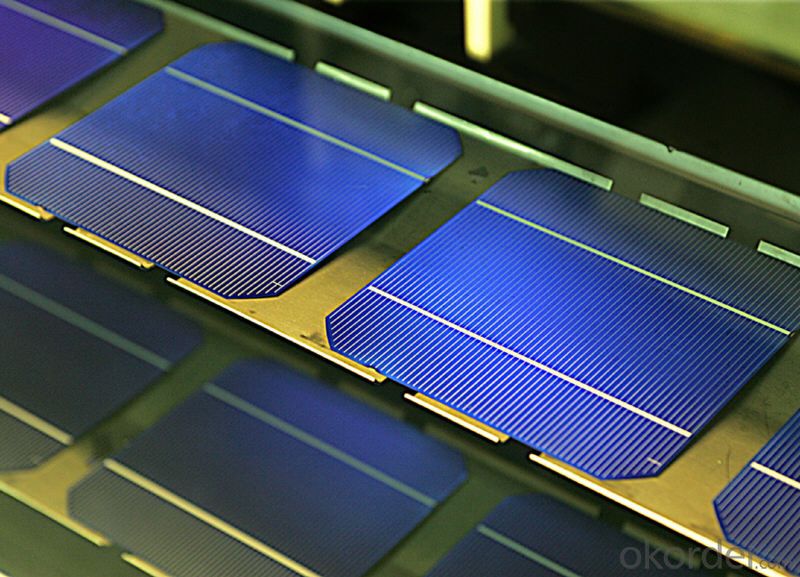

Monocrystalline Solar Grade Silicon Wafer - Mono Solar Cells 156mm*156mm in Bulk Quantity Low Price Stock 18.2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

- Up to 20.0% efficiency, one of the highest performing mono crystalline cells on the market

- Three bus bars boosts current collection over the entire cell area, leading to higher fill factors

- Blue anti-reflecting coating allows more sunlight be captured and converted to electricity

- Finer, closer fingers improves charge collections for improved energy yield

- Lower light-induced degradation leads to greater power output over the entire module lifetime

- All solar cells are tightly classified to optimize output of module

- Maximum yield and longevity due to hotspot prevention

- Premium appearance results in a highly uniform and aesthetically appealing module

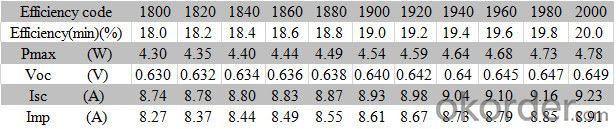

Specification

- Product Mono-crystalline silicon solar cell

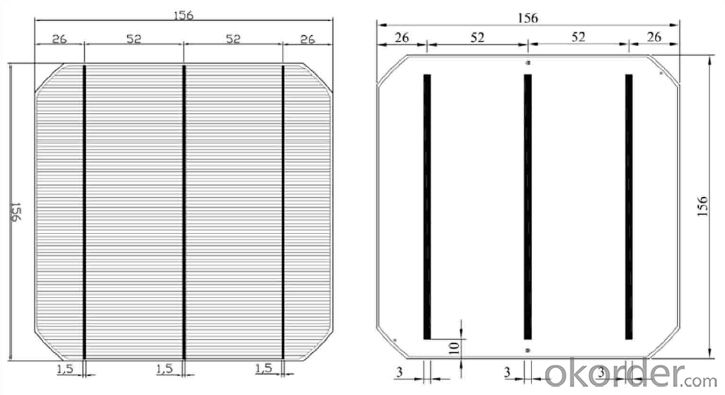

- Dimension 156 mm x 156 mm ± 0.5 mm

- Thickness 200 μm ± 30 μm

- Front 1.5 ± 0.1 mm busbar (silver)

- Silicon nitride antireflection coating

- Back 3.0 mm continuous soldering pads (silver)

- Back surface field (aluminum)

Electric performance parameters

- Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

- Imin : at 0.5 V

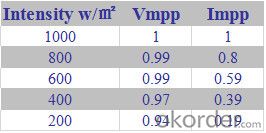

Light Intensity Dependence

Soldering Ability

- Peel Strength: > 1.0 N/mm (Pull soldered ribbon from busbar in 5 mm/s of 180°)

Dimension Figure

Quick Response

- Any time and anywhere, reply clients' email and solve all problems happen in the work at the first time.

- Remove clients doubts and offer the best solution at the first time.

- Give our clients the lastest news of the photovoltaic, update the newest stock informtion.

Production and Quality Control

- Precision cell efficiency sorting procedures

- Stringent criteria for color uniformity and appearance

- Reverse current and shunt resistance screening

- ISO9001,ISO14001 and OHSAS 18001,TUV Certificated

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q: What is the effect of doping on the bandgap of a solar silicon wafer?

- Doping in a solar silicon wafer has a significant effect on its bandgap. By selectively adding impurities to the silicon lattice, the bandgap of the material can be modified. Doping with elements such as phosphorus or boron can either increase or decrease the bandgap of silicon. N-type doping, which involves adding phosphorus, introduces extra electrons into the lattice, reducing the bandgap. This allows the material to absorb photons with lower energies, extending the wavelength range of solar absorption. P-type doping, using boron, creates "holes" in the lattice, increasing the bandgap. This enables the material to absorb photons with higher energies, expanding its efficiency in converting sunlight into electricity. Overall, doping plays a crucial role in tailoring the bandgap of solar silicon wafers to optimize their performance in photovoltaic applications.

- Q: Can solar silicon wafers be used in art installations?

- Yes, solar silicon wafers can be used in art installations. These wafers can be creatively incorporated into various artistic designs to add a unique and sustainable element to the installation.

- Q: Can solar silicon wafers be repaired?

- Yes, solar silicon wafers can be repaired to a certain extent. Small damages such as microcracks or scratches can often be repaired using various techniques, including polishing or laser-based methods. However, more significant damages, such as large cracks or broken wafers, may require replacement rather than repair.

- Q: How do solar silicon wafers perform in areas with limited sunlight?

- Solar silicon wafers do not perform as efficiently in areas with limited sunlight. The amount of sunlight directly affects the amount of energy the solar panel can generate. Therefore, in areas with limited sunlight, the performance of solar silicon wafers will be reduced, resulting in lower energy production.

- Q: What is the cost of a solar silicon wafer?

- The cost of a solar silicon wafer can vary depending on several factors such as the size, quality, and quantity being purchased. On average, a standard 156 mm x 156 mm solar silicon wafer can range from $0.10 to $0.30 per piece. However, prices may fluctuate due to market conditions and supplier negotiations.

- Q: What is the expected efficiency improvement for quantum dot solar silicon wafers?

- The expected efficiency improvement for quantum dot solar silicon wafers is significant, with some studies suggesting a potential enhancement of up to 50% compared to traditional silicon solar cells.

- Q: Can solar silicon wafers be recycled?

- Yes, solar silicon wafers can be recycled. The recycling process involves reclaiming valuable materials such as silicon, silver, and other metals from the wafers, which can then be used to produce new solar panels or other electronic devices. Recycling solar silicon wafers reduces waste and conserves resources, making it an environmentally sustainable practice.

- Q: How are solar silicon wafers recycled at the end of their life cycle?

- Solar silicon wafers can be recycled at the end of their life cycle through a multi-step process. First, the wafers are collected from old or defective solar panels. Then, they undergo a mechanical shredding process to break them down into smaller pieces. These pieces are then treated with chemicals to remove any impurities or contaminants. Next, the purified silicon pieces are melted down and formed into new wafers or ingots, which can be used in the production of new solar panels. This recycling process helps recover valuable materials and reduces the environmental impact of discarded solar panels.

- Q: How efficient are solar silicon wafers in converting sunlight into electricity?

- Solar silicon wafers are highly efficient in converting sunlight into electricity. With advancements in technology, these wafers can now achieve conversion efficiencies of up to 25%. This means that they can convert 25% of the sunlight they receive into usable electrical energy, making them a reliable and effective choice for solar energy generation.

- Q: What is the maximum temperature a solar silicon wafer can withstand?

- The maximum temperature a solar silicon wafer can typically withstand is around 250-300 degrees Celsius.

Send your message to us

Monocrystalline Solar Grade Silicon Wafer - Mono Solar Cells 156mm*156mm in Bulk Quantity Low Price Stock 18.2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords