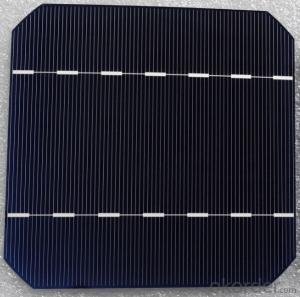

6*6 High Efficiency Mono Silicon Solar Panel Silicon Wafer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Main Characteristic

17.6%-18% High Efficiency A Grade 125mm Monocrystalline Solar Cells

1.First-class production technology and packaging technology.

2.Adopting the world's leading technology of silicon and polycrystalline silicon cells, power density, peak hours more battery power, higher conversion efficiency.

3.Beautiful, stable, easy to take down the anodic aluminum frame electric degrees and has a wind-resistant, anti-snow function.

Features

17.6%-18% High Efficiency A Grade 125mm Monocrystalline Solar Cells

1.High transmissivity low-iron tempered glass, strong aluminium frame.

2.Manufactured according to international quality and Environment Management System (ISO9001, ISO14001).

3.Low voltage-temperature coefficient allows higher power output at high-temperature condition.

Product Pictures

- Q: Is a wafer a silicon wafer and a wafer?Please try to speak more popular, can be said to be made of silicon wafers do

- It is the raw material of the semiconductor industry, which is called silicon wafer after cutting

- Q: I work in a solar cell company, do silicon chip testing on the human body what chronic harm?

- Silicon is a semiconductor material, if it is to detect the bare silicon wafer, then there is no harm

- Q: Can solar silicon wafers be used in recreational vehicles (RVs)?

- Yes, solar silicon wafers can be used in recreational vehicles (RVs). Solar panels made with silicon wafers are commonly used in RVs to harness solar energy and provide power for various appliances and systems while on the road or camping.

- Q: How is the efficiency of a solar silicon wafer measured?

- The efficiency of a solar silicon wafer is typically measured by calculating the percentage of sunlight it can convert into usable electricity. This is done by measuring the power output of the solar cell and dividing it by the power of the incident sunlight falling on the cell. The higher the percentage, the more efficient the silicon wafer is at converting sunlight into electricity.

- Q: What is the impact of surface recombination on the performance of solar silicon wafers?

- Surface recombination refers to the loss of charge carriers (electrons and holes) at the surface of solar silicon wafers, which can significantly impact their performance. It leads to reduced efficiency and lower overall power output of solar cells. Surface recombination acts as a bottleneck for charge carrier transport, limiting their lifetime and diffusion length. This results in a decrease in the effective collection of generated charge carriers, reducing the conversion of sunlight into electricity. To mitigate this impact, various surface passivation techniques are employed to minimize surface recombination and enhance the performance of solar silicon wafers.

- Q: Are there any initiatives to reduce the cost of solar silicon wafers?

- Yes, there are several initiatives underway to reduce the cost of solar silicon wafers. These initiatives include advancements in manufacturing processes, research and development of new materials, and improvements in production efficiency. Additionally, governments and organizations are providing financial support and incentives to promote the adoption of solar energy, which indirectly helps in reducing the cost of solar silicon wafers.

- Q: How is an encapsulant applied to a solar silicon wafer?

- An encapsulant is typically applied to a solar silicon wafer through a process called lamination. This involves placing the wafer between two layers of encapsulant material, such as EVA (ethylene-vinyl acetate), and then subjecting it to heat and pressure. The heat melts the encapsulant, enabling it to bond with the wafer, while the pressure ensures uniform distribution of the material and helps to remove any air bubbles. This lamination process provides protection to the solar silicon wafer from environmental factors and enhances its durability and performance.

- Q: Are there any advancements in solar silicon wafer technology on the horizon?

- Yes, there are advancements in solar silicon wafer technology on the horizon. Researchers and companies are continually working on improving the efficiency and cost-effectiveness of solar panels. Some developments include the use of thinner wafers, new manufacturing techniques, and the integration of advanced materials to enhance performance. These advancements aim to make solar energy more accessible and competitive, contributing to the growth of renewable energy adoption.

- Q: How do solar silicon wafers contribute to the circular economy?

- Solar silicon wafers contribute to the circular economy by enabling the production of renewable energy through solar panels. By harnessing the power of the sun, solar panels generate clean electricity, reducing the reliance on fossil fuels and mitigating environmental degradation. The circularity of this process lies in the fact that solar silicon wafers can be recycled and reused in the production of new panels, minimizing waste and resource depletion. This closed-loop approach promotes sustainability, reduces greenhouse gas emissions, and fosters a more circular and regenerative economy.

- Q: How are solar silicon wafers protected from water damage?

- Solar silicon wafers are protected from water damage through a combination of encapsulation and sealing techniques. The wafers are typically coated with a layer of protective material, such as glass or a specialized polymer, which acts as a barrier against water intrusion. Additionally, the edges of the wafers are sealed to prevent any water from seeping into the sensitive components. These measures ensure that the solar silicon wafers remain unaffected by water exposure, maintaining their efficiency and longevity.

Send your message to us

6*6 High Efficiency Mono Silicon Solar Panel Silicon Wafer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords