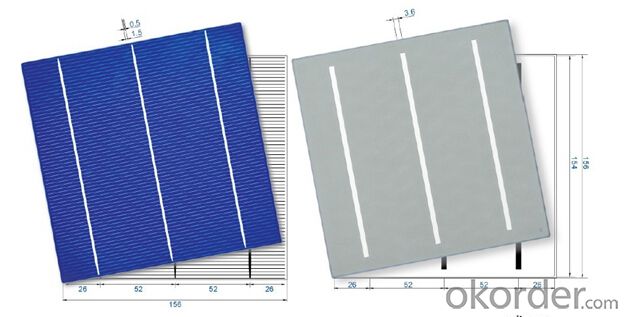

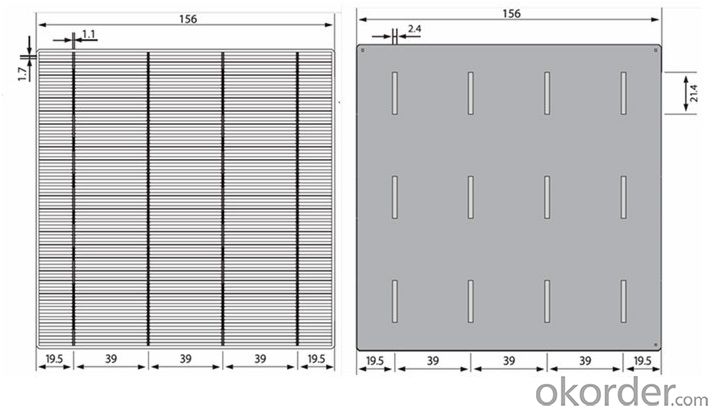

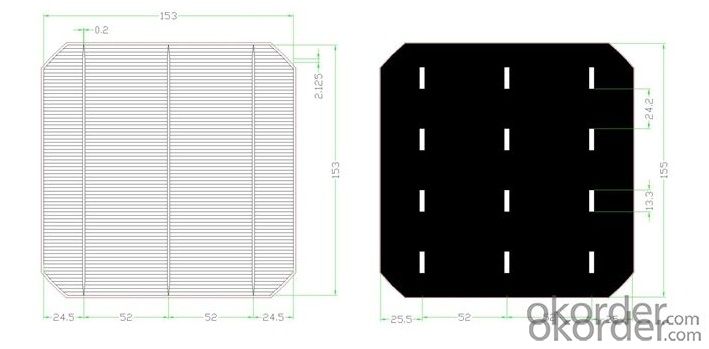

Silicon Wafer Solar Grade A 156x156mm Poly Stable Quality Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

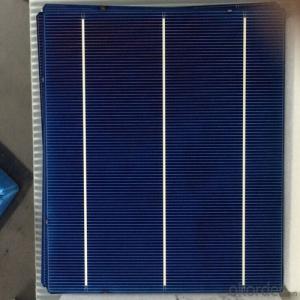

Grade A 156x156mm Poly Stable Quality Solar Cell

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Solar Module Specifications

Mono 80W—100W

Module | Type (36 Series) | |||||

Encapsulation | Glass/EVA/Cells/EVA/TPT | |||||

Parameters | SNM-M80(36) | SNM-M85(36) | SNM-M90(36) | SNM-M95(36) | SNM-M100(36) | |

Max power | Pm(W) | 80W | 85W | 90W | 95W | 100W |

Tolerance | +/-3% | |||||

Open circuit voltage | Voc(V) | 21.2 | 21.8 | 21.8 | 22.3 | 22.6 |

Short circuit current | Isc(A) | 4.84 | 5.00 | 5.30 | 5.44 | 5.68 |

Max. power voltage | Vmp(V) | 17.5 | 18.0 | 18.0 | 18.5 | 18.5 |

Max. power current | Imp(A) | 4.57 | 4.72 | 5.00 | 5.14 | 5.40 |

Dimensions | (L*W*H) | 1200x540x35mm | ||||

Net Weight | (kg) | 9 | ||||

Max. system voltage | (V) | 1000VDC | ||||

Operate Temp. Scope | -40/+85'C | |||||

Resistance | 227g steel ball fall down from 1m height and 120m/s wind | |||||

Warranty | Pm is no less 90% in 10 years and no less 80% in 25 years | |||||

STC | (Standard Test Condition: 1000W/m2, AM1.5, and 25'C) | |||||

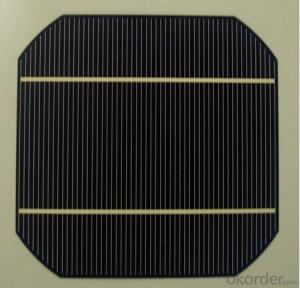

Picture show

- Q: Monocrystalline silicon processing technology

- Most photovoltaic equipment suppliers buy chip wire. They generally grow silicon ingots or silicon blocks and process silicon materials into wafers, which are eventually sold to photovoltaic cell manufacturers for the production of batteries. The installed capacity of the industry's most successful application of B5 wire materials company HCT system more than 500 units, is a benchmark in the field of photovoltaic chip products nclusionIn the field of photovoltaic technology, wire reduces wafer thickness and reduce the material loss in the cutting process, thereby reducing the power consumption of the solar silicon materials. (therefore, wire saw technology to reduce the cost per watt of solar energy and eventually to achieve grid parity has played a crucial role. The latest and most advanced wire technology brings a lot of innovation, improve the productivity and the thinner silicon wafers to reduce the consumption of silicon materials.

- Q: Can solar silicon wafers be used in military or defense applications?

- Yes, solar silicon wafers can be used in military or defense applications. They can be integrated into various military equipment and systems such as remote sensors, surveillance systems, unmanned aerial vehicles (UAVs), and portable power systems for soldiers in the field. Solar silicon wafers provide a reliable and sustainable source of power in remote or hostile environments, reducing the dependence on traditional fuel sources and increasing operational capabilities.

- Q: What is the average lifespan of a solar silicon wafer?

- The average lifespan of a solar silicon wafer can vary depending on various factors such as the quality of the wafer, the manufacturing process, and the conditions in which it is used. However, on average, a solar silicon wafer can last anywhere from 25 to 30 years.

- Q: How much is the thickness of the silicon wafer

- And two knives. We do DIP package, 4 inch wafer to thin to 0.300mm; 6 inch wafer to be reduced to about 0.320mm, error 0.020mm.

- Q: What is the role of the back contact on a solar silicon wafer?

- The role of the back contact on a solar silicon wafer is to provide electrical contact to the bottom layer of the solar cell. This contact allows for the collection and extraction of the generated electrical current, ensuring efficient energy conversion. Additionally, the back contact also acts as a reflective surface, enhancing light absorption and reducing energy loss in the solar cell.

- Q: What is the typical cost of a solar silicon wafer?

- The typical cost of a solar silicon wafer can vary depending on various factors such as the size, quality, and quantity being purchased. However, on average, a solar silicon wafer can range in cost from around $0.10 to $0.50 per watt, with larger orders typically resulting in lower prices per wafer.

- Q: How are solar silicon wafers packaged for transportation and installation?

- Solar silicon wafers are typically packaged for transportation and installation in protective materials such as foam or plastic trays. These trays are designed to hold multiple wafers securely and prevent damage during transit. Additionally, the wafers are often further protected by placing them in cardboard boxes or crates, which provide additional stability and safeguard against any potential impact during transportation.

- Q: How are solar silicon wafers protected from extreme weather events?

- Solar silicon wafers are protected from extreme weather events through the use of specialized materials and coatings. These protective layers shield the wafers from moisture, temperature fluctuations, and other environmental factors that could potentially damage them. Additionally, solar panels are designed to withstand high winds and heavy rain, ensuring their resilience during storms and other severe weather conditions.

- Q: How do solar silicon wafers contribute to job creation in the renewable energy sector?

- Solar silicon wafers play a crucial role in the manufacturing of solar cells and panels, which are essential components of renewable energy systems. The production and assembly of these wafers require skilled labor and expertise, leading to job creation in the renewable energy sector. Additionally, the increasing demand for solar energy worldwide has created opportunities for employment in various stages of the value chain, from raw material extraction to research and development. Therefore, solar silicon wafers contribute significantly to job creation in the renewable energy sector by driving the growth and expansion of solar power industries globally.

- Q: What is the role of a glass cover in a solar silicon wafer?

- The role of a glass cover in a solar silicon wafer is to protect the wafer from external elements such as dust, moisture, and mechanical damage. It also acts as a barrier against UV radiation and helps to maximize the efficiency of the solar cell by allowing maximum transmission of sunlight while minimizing reflection and absorption losses. Additionally, the glass cover provides electrical insulation and ensures long-term durability of the solar module.

Send your message to us

Silicon Wafer Solar Grade A 156x156mm Poly Stable Quality Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches