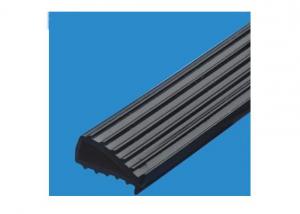

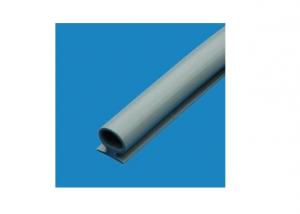

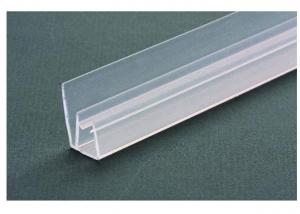

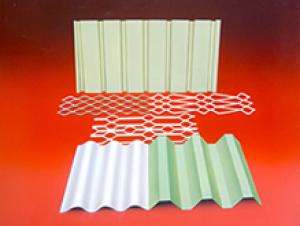

Plastic Extrusion Profiles

Plastic Extrusion Profiles Related Searches

Extruded Plastic Profiles Profile Extrusion Multi Plastics Extrusion Aluminum Extrusions Aluminum Extrusion Shapes Plastic Extrusion Melbourne Plastic Profiles Bamber Bridge Aluminum Extrusion Plate Aluminium Extrusion Plastic Shapes Aluminum Extrusion Framing Large Plastic Panels Plastic Injection Molds Plastic Tubing Extruded Rubber Seals Extruded Polystyrene Xps American Thermoplastic Extrusion Company High Temperature Plastic Rectangular Plastic Tubing Plastic Document Tubes Clear Plastic Panels Extruded Aluminum Track Extruded Polystyrene Thermal Conductivity Curved Plastic Tubing Trim Plastics U Shaped Plastic Molding Rectangular Plastic Pipe Aluminum Extruded Tubing Plastic Cores Tubes Plastic Cigar TubesPlastic Extrusion Profiles Supplier & Manufacturer from China

Plastic Extrusion Profiles are versatile and widely used products in various industries, offering a range of benefits such as durability, cost-effectiveness, and design flexibility. These profiles are manufactured through a process called extrusion, where plastic material is heated and forced through a die to create a continuous profile with a specific cross-sectional shape. The applications of Plastic Extrusion Profiles span across numerous sectors, including construction, automotive, packaging, and consumer goods. They are commonly used for creating structural components, decorative elements, and functional parts that require lightweight and robust materials. The usage scenarios for these profiles are vast, as they can be tailored to meet specific requirements in terms of size, shape, and material properties.Okorder.com is a leading wholesale supplier of Plastic Extrusion Profiles, boasting a comprehensive inventory that caters to the diverse needs of customers from different industries. As a reliable source for these profiles, Okorder.com ensures that the products are of high quality and meet the necessary standards for various applications. The company's commitment to customer satisfaction is evident in its extensive range of Plastic Extrusion Profiles, which are designed to provide optimal performance and longevity in their respective usage scenarios. By partnering with Okorder.com, customers can expect to receive top-notch products and services, making it a preferred choice for sourcing Plastic Extrusion Profiles.

Hot Products