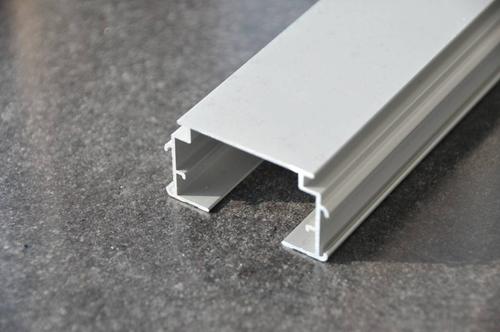

Aluminum Extrusions Profiles for Cable Trough

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Profile for Cable Trough

Usage:Cable trough

Surface:Anodizing,Powder coating, Electrophoresis

Alloy:6063

Size:according to customer’s requirement

Advantage:Durability, good corrosion resistance and lightweight

Package:Normal paper package and soft plastic interleaving each profile to protect the surface. In case of any special package, additional packing cost will be charged.

product details | |

Material | Alloy:6063,6061,6060,6005,7005 |

State | Mainly T5/T6 |

Thickness | above 1.0mm;recommend 1.2mm and above,customized available |

Normal Anodizing thickness | 8-12 micro |

Normal power coating thinkness | 600-100 micro |

Tensile strength | ≥ 16 mpa |

Yield strength | ≥ 110 mpa |

Extensibility | ≥ 8% |

Hardness(HW) | ≥ 8 |

Surface Treatment | 1) Mill finish |

Length | 1m-7m,Customized is available |

Packing | Kraft paper, EPE Fram, Shrink film, Composite paper,etc |

Standard | QC:ISO, SGS |

Time of samlple | 10-18days,including making mould |

Deep precessing ability | Drill holes,stretch bneding,milling,welding,fabrication etc |

Order process | 1.drawing/colors/price confirmed |

Trade terms | FOB Qingdao, CIF or CFR to the appointed port. |

Payment terms | T/T ,L/C,etc |

MOQ | 1*20 FCL |

- Q: This question seeks to understand the various types of aluminum profiles that are specifically utilized in the construction of railings and fences.

- <p>Aluminum profiles for railings and fences come in various types, each designed for specific applications and aesthetic preferences. Common types include: 1) Rectangular profiles, which are versatile for both commercial and residential settings; 2) Square profiles, offering a modern look and are often used in minimalist designs; 3) Round profiles, providing a classic appearance suitable for traditional or vintage styles; 4) Slotted profiles, which allow for easy assembly and are popular for their adjustability; 5) Hollow profiles, known for their strength and lightness, ideal for high-load applications; 6) Angled profiles, used to create corners and intersections in railing and fence designs. Each type can be further customized in terms of size, thickness, and finish to meet specific project requirements.</p>

- Q: Are aluminum profiles suitable for structural applications?

- Yes, aluminum profiles are suitable for structural applications. Aluminum is a lightweight and highly versatile material that offers excellent strength-to-weight ratio, corrosion resistance, and durability. These properties make it ideal for various structural applications such as architectural frameworks, bridges, aerospace structures, automotive frames, and industrial equipment. Additionally, aluminum profiles can be easily fabricated, welded, and joined, allowing for efficient construction and customization. With proper design and engineering considerations, aluminum profiles can provide the necessary strength and stability required for structural applications.

- Q: It is now the most urban rail trains, as well as the manufacturing methods and processes of large parts profiles used in the manufacture of CRH3 type emus.

- Extrusion; preheating; mold preheating; extrusion quality inspection (optical projection measurement); cutting; heat treatment; quality assurance tests; mechanical properties; cross sectional metallography; electrical conductivity) shipment..

- Q: What are the dimensions and sizes of aluminum profiles?

- The dimensions and sizes of aluminum profiles can vary greatly depending on their intended use and design. They can range from small and narrow profiles, such as 10mm x 10mm square tubes, to larger and wider profiles, such as 100mm x 100mm square tubes. Additionally, aluminum profiles can come in various shapes, including square, rectangular, round, and custom shapes, to accommodate different applications and structural requirements. It is important to consult specific product catalogs or manufacturers for precise dimensions and sizes of aluminum profiles.

- Q: Are aluminum profiles suitable for partition walls?

- Partition walls can indeed be constructed using aluminum profiles. Aluminum, a material known for its lightweight and durability, is frequently utilized in the construction industry because of its versatility and strength. It offers exceptional structural support and can be easily tailored to meet diverse design specifications. Moreover, aluminum profiles provide a sleek and contemporary appearance, rendering them highly sought after for modern interior designs. Furthermore, aluminum is resistant to corrosion and necessitates minimal upkeep, making it a cost-effective alternative for partition walls. In conclusion, aluminum profiles are a dependable and pragmatic option for producing robust and visually appealing partition walls.

- Q: How to sell and sell industrial aluminium profiles?

- For the industrial aluminum profile enterprise, this is the most valuable customer resource, and also is the high-quality customer we usually call. Of course, the quality of customer mining, the most important thing is to discuss and communicate with customers. We must start from the position of customers, understand their requirements for products, know what they want to achieve the desired, can use their brains, for them to benefit by mutual discussion, analysis and reflection, so customers are thinking, anxious customers, so in fact, let customers choose our is the logical thing. It should be said that this is the most critical moment in the whole sale, so don't let yourself lose here.

- Q: Can aluminum profiles be utilized for creating distinctive architectural designs, and if yes, what are the ways to achieve this?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, light weight, and corrosion resistance, which allow for innovative and sustainable building solutions. Architects can use aluminum profiles in various ways: as structural components in curtain walls, as decorative elements in facades, or as supports in roof structures. The profiles can be custom-cut and shaped to fit specific design requirements, and they can be combined with glass or other materials to create a harmonious blend of aesthetics and functionality. Additionally, aluminum's recyclability and low maintenance make it an environmentally friendly choice for architectural projects.</p>

- Q: Can aluminum profiles be used in food-grade applications?

- Yes, aluminum profiles can be used in food-grade applications. Aluminum is a non-toxic, lightweight, and corrosion-resistant metal that is commonly used in the food industry. It is often used to fabricate food processing equipment, such as conveyor systems, tanks, shelves, and frames. Aluminum profiles can also be used in the construction of cleanrooms and other sanitary environments where food is processed or stored. Additionally, aluminum is easily cleaned and sanitized, making it a suitable material for food-grade applications. However, it is important to ensure that the aluminum profiles used are specifically designed for food-grade applications and comply with relevant regulations and standards to ensure the safety and quality of the food being processed or stored.

- Q: Can aluminum profiles be used for creating lighting fixtures?

- Yes, aluminum profiles can be used for creating lighting fixtures. Aluminum is a popular material choice for lighting fixtures due to its lightweight nature, durability, and corrosion resistance. It is also easily shaped and machined, making it suitable for creating various designs and styles of lighting fixtures. Additionally, aluminum profiles can be powder-coated or anodized to enhance their appearance and provide additional protection against wear and tear. The versatility and aesthetic appeal of aluminum make it an ideal choice for creating lighting fixtures in a wide range of settings, including residential, commercial, and industrial applications.

- Q: Is it possible to manufacture aluminum profiles in unique shapes or dimensions tailored for particular uses?

- <p>Yes, aluminum profiles can be made into custom shapes or sizes for specific applications. Manufacturers can customize aluminum profiles through various processes such as extrusion, cutting, bending, and machining to meet the unique requirements of different projects. This flexibility allows for the creation of specialized components that can be used in a wide range of industries, including construction, automotive, aerospace, and more.</p>

Send your message to us

Aluminum Extrusions Profiles for Cable Trough

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords