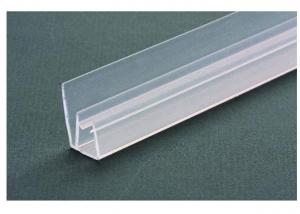

Plastic Extrusion for Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Meters pc

- Supply Capability:

- 10000 Meters per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Plastic Extrusion For Window

1.Professional OEM & Exporter

2.Professional service.Custom is God

3.Favorable price & good quality

Specifications of Plastic Extrusion For Window

1.Professional OEM & Exporter

2.Professional service.Custom is God

3.Favorable price & good quality

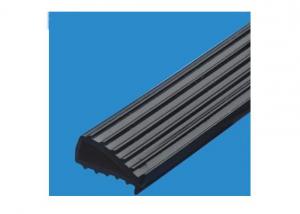

Type of Plastic Extrusion For Window

1.Sponge/Foam Extrusion.

2.Solid/compact Extrusion.

3.Co-extruded seal strip.

4.PVC&Rubber compound extrusion.

5.All these can be with metal insertion.

Features of Plastic Extrusion For Window

Widely used in industry,agriculture,including building,automotive sealing profiles, sealing or decorating of windows, doors, curtain walls, cars etc,avoiding dust,water or air to leak inside the cabin,as

it's good ozone-resistant,chemical resistant,Weather&temperature resistant and has excellent

appearance in flexibility Anti-aging, antiradiation.

Range of Plastic Extrusion For Window

Manufacture wide range of rubber profile,rubber seals,rubber strip, tubing, cord or custom rubber extrusion

shapes for Auto industry,mechanical,construction,etc ,the extrusions also can be made in PVC. Our rubber

extrusion includes but not limited , D sponge Seal, Rubber bulb, rubber U channel, T section seal, Edge Trim, Flock

lined rubber, flat square sponge rubber, window rubber,weather strip etc.Custom design could be available.

General data of Plastic Extrusion For Window

Material: EPDM, Nitrile(NBR), Neoprene(CR), Silicon, Viton, SBR, Natual rubber and various other basic raw materials.

Hardness: From 35 to 85 Share A.

Temperature resistance:-50 to +260 Degrees Centigrade (up to 300C for short periods).

Various color are available,like black,red,white,blue.etc.

Grade:Industrial grade;Food grade(FDA approval).Medical grade.

Size available:1mm to 150mm high and width

Length:continous.

Different sections as per your sample or drawings,do believe that we can supply competitive price &quality with best service.

- Q: Where does the car use the most rubber parts?

- The most used rubber on the car must be the tires. The second is the rubber pad at the joint, as well as the rubber sleeve for the movable joint and the rubber seal for sealing. Apart from tires, the rest of the world is the most difficult to use because of the different models.

- Q: What are the uses of rubber materials in automobiles?

- Hose for automobile. No matter what the car has a lot on the root rubber tube, such as radiator pipe, air-conditioning pipe, water pipe, gas pipe and so on, because these tubes need to experience vibration and bumps in the car environment, so we have various performance requirements, it must be used in automotive rubber parts.

- Q: The car roof strip off with what can be glued glue?

- HY-T160 PP/PE slow dry glue is mainly used for bonding plastic products such as: stick to polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), ABS, nylon, sponge, foam film, etc.; the organic glass, rubber, metal, wood, bamboo fabric paper also has good adhesion, especially for plastic and metal and non-metal materials are glued cross bonding has more originality, is the bonding material industry, household appliances industry, radio decoration, craft toys, insulation materials, packaging and printing industry is the ideal.

- Q: Where does the rubber from the car come from?

- Polybutadiene rubber is prepared by the solution polymerization of butadiene butadiene rubber, with excellent cold resistance, abrasion resistance and elastic rubber tires, but also has good anti-aging properties. Polybutadiene rubber is mostly used in the production of tires, a small part for manufacturing cold products, cushioning materials and belt and rubber shoes. Butadiene rubber drawback is the poor tear resistance, wet skid resistance is not good.

- Q: What kind of rubber does it need to produce automobile tyres?

- Inner tube, general, natural, butyl gum. Tire for general use, natural, SBR, polybutadiene rubber.

- Q: What kinds of materials are there on the skid ramp?

- Performance characteristics:1, there is no obvious vibration when the vehicle is moving;2, surface roughness uniformity, small fluctuations, large damping;3, even if there is water or ice, the vehicle is also safe;4, good compression resistance, high surface hardness, wear-resistant;5, the service life of more than 10 years;6 、 short construction cycle and beautiful color.

- Q: The car tire two what is the difference? Which one is better? 1) glue inside; 2) prick holes and glue bars into it

- Inside the glue to fire up is the best, very hot rice, do not worry about the wound to leak, if it is in the surface of the tyre with injections, tie tape! Cold patching is very convenient, but it doesn't take me long!

- Q: Horsen armored vehicle chassis paint spray type construction site vehicle anti rust paint drying glue please chassis armor

- It is non-toxic, high covering rate, high adhesion, can be sprayed on the vehicle chassis, wheel hub, oil tank, automobile panels, luggage and other exposed parts, fast drying to form a layer of strong elastic protective layer can prevent the stone and gravel impact, avoid moisture, acid rain, salt erosion of metal for vehicle chassis, prevent rust and corrosion protection of the chassis, the owner of the traffic safety.

- Q: What is the difference between the bottom rubber and the foot pad?

- When it comes to floor sizing, all the chairs should be removed, whether they are hand sewn or shaped, and they will be a whole after they are finally put on the bus.Car mats are not the same, are generally five, and now popular Ottomans are special car, that is to say, in general, it is necessary to shop a layer of glue, and then buy a foot pad shop. Because if you want to dismantle the earth glue, it is necessary to dismantle the seat, inconvenient, and it does not dust, no water absorption. The Ottomans are small in size and easy to disassemble. When the pads are dirty, they can be cleaned as soon as they are taken down, while the pads have a protective effect on the glue or carpet of the car.

- Q: Small car door open to stick on the edge

- HY-308 glue is used for rubber sticking all kinds of metal.Such as rubber, iron, rubber, aluminum, rubber, steel, rubber, steel, rubber, carbon steel, rubber, cast iron, rubber, stainless steel, rubber, aluminum alloy, rubber, titanium alloy, rubber, zinc alloy and other materials.

1. Manufacturer Overview

| Location | Zhejiang,China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Ningbo |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Plastic Extrusion for Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Meters pc

- Supply Capability:

- 10000 Meters per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords