Aluminum Corner Extrusion Machining Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

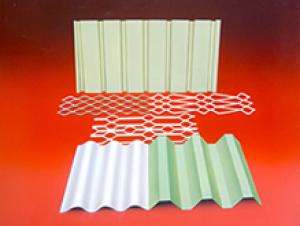

MACHINING PROFILE

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: How do you cut and shape aluminum profiles?

- To achieve the desired outcome and utilize the available tools, there are various methods for cutting and shaping aluminum profiles. Here, we present three commonly employed techniques: 1. Hacksaw or Miter Saw: This method is the most straightforward and accessible. By employing a hacksaw or a miter saw equipped with an aluminum cutting blade, you can mark the desired length on the profile and cautiously cut through it. It is crucial to maintain a secure grip on the profile and execute deliberate, unhurried cuts to prevent excessive vibration or the blade from getting stuck. 2. Power Saw or Circular Saw: When dealing with larger or thicker aluminum profiles, employing a power saw or circular saw equipped with a specialized aluminum cutting blade can expedite the process and make it more manageable. After measuring and marking the desired length on the profile, firmly secure it in place. Utilize the power saw to gradually and steadily cut through the profile, ensuring a firm grip and maintaining control throughout the procedure. 3. File or Grinder for Shaping: Once the profile is cut to the desired length, it may be necessary to shape or smooth the edges. This can be accomplished by utilizing a file or grinder equipped with an aluminum grinding wheel or sanding disc. Meticulously work the file or grinder along the edges, shaping or smoothing them as required. Be careful not to exert excessive pressure, as aluminum quickly heats up and may warp or sustain damage. When working with aluminum profiles, remember to wear appropriate safety gear, such as gloves and eye protection. Furthermore, it is advisable to practice on scrap pieces beforehand to familiarize yourself with the techniques and tools before commencing work on the final product.

- Q: Are aluminum profiles suitable for use in roofing systems in areas with high wind conditions?

- <p>Yes, aluminum profiles can be used for roofing systems in windy regions. Aluminum is a lightweight and durable material that can withstand high winds. It is often used in the construction of roofing systems because of its strength and resistance to corrosion. Additionally, aluminum profiles can be designed to meet specific wind load requirements, making them suitable for areas prone to strong winds. However, the design and installation of the roofing system must be done correctly to ensure it can handle the wind forces.</p>

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems for residential buildings?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems in residential buildings. They are known for their durability, corrosion resistance, and low thermal conductivity, which makes them ideal for creating thermal barriers. Aluminum profiles can support the structure of the insulation system, providing a stable framework while also contributing to energy efficiency by reducing heat transfer. However, it's important to ensure that the profiles are properly sealed and insulated to prevent thermal bridging and to maintain the overall insulation performance of the building envelope.</p>

- Q: Can aluminum profiles be utilized for creating distinctive architectural designs, and if yes, what are the ways to achieve this?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, light weight, and corrosion resistance, which allow for innovative and sustainable building solutions. Architects can use aluminum profiles in various ways: as structural components in curtain walls, as decorative elements in facades, or as supports in roof structures. The profiles can be custom-cut and shaped to fit specific design requirements, and they can be combined with glass or other materials to create a harmonious blend of aesthetics and functionality. Additionally, aluminum's recyclability and low maintenance make it an environmentally friendly choice for architectural projects.</p>

- Q: Can aluminum profiles be used for outdoor applications?

- Yes, aluminum profiles can be used for outdoor applications. Aluminum is a highly versatile and durable material that is resistant to corrosion, making it suitable for use in outdoor environments. It has excellent weather resistance and can withstand exposure to sunlight, rain, and temperature variations without deteriorating. Aluminum profiles are commonly used in outdoor applications such as construction, architecture, transportation, and outdoor furniture. They offer strength, stability, and longevity, making them a popular choice for outdoor projects. Additionally, aluminum profiles can be finished with protective coatings or anodized to further enhance their resistance to outdoor elements.

- Q: Can aluminum profiles be used for window frames?

- Yes, aluminum profiles can be used for window frames. Aluminum is a popular material choice for window frames due to its durability, strength, and resistance to corrosion. It is lightweight, easy to shape, and can withstand various weather conditions, making it a suitable option for window frames. Additionally, aluminum profiles can be customized to fit different window sizes and designs, making them a versatile choice.

- Q: Can Linqu aluminum profile factory have 100 home?

- Some of the largest Huajian aluminum industry in Linqu there is no doubt that there are a lot of good after scale manufacturers, such as Albert Wei Sheng Jian Zhonghao new east to east of Yangtze River following so little that it is not representative of the product but a superb collection of beautiful things, not in Linqu, most of the manufacturers is YISHION aluminum ingots as raw material, processing technology is advanced basically, can ensure the quality of products. Louzhu should mention the one hundred, because there is only a scale can reach 53 (news reports), the number of small scale is much larger than this number, so the one hundred aluminum manufacturers should be more than enough, thank you for adopting!

- Q: Can aluminum profiles be used for soundproofing?

- Yes, aluminum profiles can be used for soundproofing. Aluminum profiles can be combined with soundproofing materials such as acoustic foam or rubber gaskets to create an effective sound barrier. Additionally, aluminum profiles have the advantage of being lightweight and easy to install, making them a practical choice for soundproofing purposes.

- Q: This question asks whether aluminum profiles can be utilized for constructing exterior walls and seeks reasons for their potential use.

- <p>Yes, aluminum profiles can be used for exterior walls. They are chosen for their durability, corrosion resistance, and low maintenance requirements. Aluminum is lightweight, which makes it easier to handle and install. It also has excellent thermal performance, allowing for energy-efficient construction. Additionally, aluminum profiles can be powder coated or anodized, offering a wide range of colors and finishes, enhancing the aesthetic appeal of the building. Their strength and flexibility make them suitable for various architectural designs and structural applications.</p>

Send your message to us

Aluminum Corner Extrusion Machining Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords