Round Aluminum Extrusion Profiles for Aviation and Aerospace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

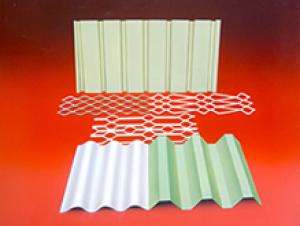

Due to fine corrosion resistance, sufficient strength, excellent process performance and welding property, aluminum alloys are widespread applied in the fields of building’s structure, windows & doors, ceilings, decoration faces etc. the SWA’s aluminum products for architecture & decoration are primarily comprised of color coated sheet and bare sheet for coating, curtain wall sheet, as well as 7 series of ordinary window & door profiles, 3 series of profiles for heat-insulated window & door, 5 series of profiles for visible-frame curtain wall, 7 series of profiles for hidden-frame curtain wall.

SWA’s architectural & decorative aluminum products are entitled as “Satisfactory Product” by the Client Committee of China Consumer Association.

It was the “Recommended Products” designated by the China Architectural Decoration and Fitting Association.

SWA’s bare sheet for coating (2002), color coated sheet (1998, 2001, 2004), architectural profiles (2003) have been commented as the “Famous Brand Product of Chongqing”.

SWA’s color coated aluminum sheets and curtain wall Al sheets, that were developed and put into market in batches in early 1990s, have filled a vacancy domestically.

- Q: Can aluminum profiles be utilized in creating distinctive architectural structures?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, lightweight, and corrosion resistance. Architects can utilize aluminum's flexibility to design complex structures, such as intricate facades, modern window systems, and innovative support frameworks. Aluminum's adaptability allows for both functional and aesthetically pleasing designs, making it a popular choice in contemporary architecture.</p>

- Q: Can aluminum profiles be used in the construction of stadium seating systems?

- Indeed, stadium seating systems can utilize aluminum profiles for their construction. Aluminum, being both lightweight and long-lasting, is frequently employed in a multitude of construction applications, including stadium seating systems. It presents numerous benefits, such as resistance to corrosion, a high strength-to-weight ratio, and ease of fabrication. By customizing and assembling aluminum profiles, seating structures that are sturdy, stable, and aesthetically pleasing can be easily created. Moreover, due to its lightweight nature, aluminum allows for simpler installation and transportation, making it a financially prudent choice for stadium seating systems. All in all, when considering their durability, versatility, and strength, aluminum profiles emerge as an appropriate selection for constructing stadium seating systems.

- Q: Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. They are lightweight, durable, and easy to assemble and disassemble, making them ideal for creating versatile and portable booth structures. Additionally, aluminum profiles offer a sleek and modern aesthetic, allowing for customization and branding opportunities.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Yes, aluminum profiles are generally suitable for use in chemical processing environments. Aluminum has excellent corrosion resistance properties and can withstand various chemicals, acids, and bases. Additionally, aluminum profiles can be further enhanced with protective coatings or anodization to provide even greater resistance to chemical exposure. However, the suitability may depend on the specific chemicals and conditions involved, so it is important to consult with experts or suppliers to ensure the best choice of aluminum profiles for a particular chemical processing environment.

- Q: This question asks for methods to ensure that aluminum profiles used in a construction project adhere to safety standards.

- <p>To ensure that the aluminum profiles used in your building project meet safety standards, you should source materials from reputable suppliers who provide certified products. Check for compliance with relevant standards such as ASTM, ISO, or local building codes. Request material certifications and test reports that confirm the profiles' strength, durability, and resistance to environmental factors. Engage a qualified engineer to review the specifications and design of the aluminum profiles to ensure they meet structural requirements. Conduct regular inspections during construction to verify that the profiles are installed correctly and are free from defects. Finally, maintain proper documentation of all materials and inspections to provide a traceable record of compliance with safety standards.</p>

- Q: Can aluminum profiles be used in agricultural applications?

- Yes, aluminum profiles can be used in agricultural applications. Aluminum is a versatile and durable material that can withstand various environmental conditions. It can be used for constructing greenhouse frames, irrigation systems, equipment supports, and other agricultural structures. Aluminum profiles offer excellent resistance to corrosion, are lightweight, and have high strength-to-weight ratio, making them suitable for use in agricultural applications.

- Q: What are aluminum profiles used for?

- Aluminum profiles have a wide range of applications in various industries. Construction and architecture are one of the primary uses of aluminum profiles. They are commonly employed in the framing of windows, doors, and curtain walls due to their lightweight yet durable characteristics. Modular structures like exhibition stands, trade show booths, and temporary shelters also utilize aluminum profiles in their construction. In the automotive industry, aluminum profiles play a crucial role in manufacturing components such as vehicle frames, roof rails, and trim parts. The lightweight properties of aluminum make it an excellent choice for enhancing fuel efficiency and reducing overall vehicle weight. Industrial machinery and equipment production also heavily relies on aluminum profiles. These profiles are used to construct machine frames, conveyor systems, and assembly lines. The versatility of aluminum profiles allows for easy customization and modification to meet specific industrial requirements. Furthermore, aluminum profiles find extensive use in furniture manufacturing and interior design. They are widely utilized in constructing shelving units, workstations, display cabinets, and partitions due to their aesthetic appeal, durability, and resistance to corrosion. The electrical and electronics industry also extensively utilizes aluminum profiles. They are employed in the manufacturing of heat sinks, enclosures, and mounting brackets. The excellent thermal conductivity of aluminum effectively dissipates heat, making it an ideal choice for electronic devices. In summary, the versatility, lightweight nature, corrosion resistance, and ease of customization make aluminum profiles highly sought after in numerous industries. They offer a wide range of applications in the construction, automotive, machinery, furniture, and electronics sectors.

- Q: What are the different sizes and dimensions of aluminum profiles?

- Aluminum profiles come in a wide range of sizes and dimensions to cater to various industrial and construction needs. These profiles are typically available in different shapes, such as angles, channels, beams, tubes, and bars, each with their own unique dimensions. For angle profiles, the common sizes range from 1/2 inch to 6 inches, with thickness measurements varying between 1/16 inch to 1/2 inch. These profiles are typically used for structural applications, reinforcements, and framing. Channel profiles are available in dimensions ranging from 1/2 inch to 8 inches, with thickness measurements varying between 1/8 inch to 1/2 inch. These profiles are commonly used for framing, support structures, and edge protection. Beam profiles have varying dimensions, including heights ranging from 1 inch to 12 inches and flange widths from 1 inch to 6 inches. The thickness of these profiles can range from 1/8 inch to 1/2 inch. Beam profiles are often used for load-bearing applications, such as bridges, buildings, and heavy machinery. Tube profiles come in a variety of sizes, including outer diameters ranging from 1/2 inch to 12 inches, and wall thicknesses between 1/16 inch to 1/2 inch. These profiles are commonly utilized in applications requiring fluid transportation, structural support, and decorative purposes. Finally, aluminum bars are available in various dimensions, such as widths ranging from 1/8 inch to 6 inches, and heights from 1/8 inch to 2 inches. The thickness of these bars can vary from 1/8 inch to 1/2 inch. Aluminum bars are commonly used for structural support, framing, and decorative purposes. It's important to note that these dimensions are not exhaustive and may vary depending on the manufacturer and specific requirements of the project. It is recommended to consult with the manufacturer or supplier to determine the exact sizes and dimensions available for a specific aluminum profile.

- Q: The side wall of the box body is a heat sink, and the exposed end of the heat radiating fin can not damage the surface, and the inner surface is made of four M3h6 internal thread nut columns, which is welded? Or press riveting? Heat sink is extruded aluminum profile, the thickness of 5.5mm, slotted deep 2.5mm, how should this process? Do you have this nut column?

- The blind hole press rivet nut column is installed on the thin plate:In the use of riveted bolts in installation and method and principle have been identified, but the riveted bolts still need special riveting equipment to operate, which guarantees the performance of essential factor riveted bolts can keep stable after installation in the. When installing, press the head of the riveting press and the pressure stud to balance vertically, and press down evenly.Rivet nut column and riveted bolts or nuts column, is a fastener used in sheet metal, sheet metal, chassis, cabinet, rivet nut column and its shape is hexagonal, the other end is cylindrical, the middle of the six corners with a cylindrical recess, its shape is internal thread holes through the press six preset angle head into the sheet inside (aperture preset holes are slightly larger than the outer diameter of cylindrical pressure rivet studs) around the hole to produce plastic deformation, the deformation part is squeezed into the slot standoffs in the rivet nut column riveting in thin plate thus, the effective fixed threaded on the sheet.

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- third, and four digits:Pure aluminum: represents the original alloyAlloy: the designation of individual alloys"- >: the back of Hn or Tn indicates the condition of work hardening or the symbol of heat treatment state-Hn: indicating the symbol for non heat treated alloys-Tn: a symbol for heat treatment alloysT5By cooling the high temperature molding process, and then the artificial aging state. Applied by cooling high temperature molding process, not through the cold processing (for straightening and leveling, but does not affect the mechanical properties of the limit), to artificial aging products.

Send your message to us

Round Aluminum Extrusion Profiles for Aviation and Aerospace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords