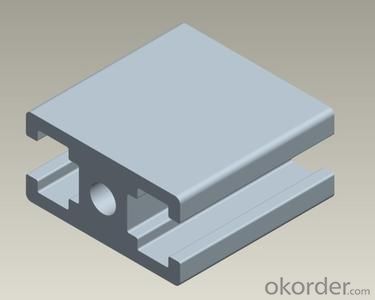

Aluminum Standard Industrial Aluminium Extrusion Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with concrete or masonry?

- One effective method to prevent galvanic corrosion when combining aluminum profiles with concrete or masonry is to use a protective barrier. Applying a suitable coating or corrosion-resistant material on the aluminum surface can create a barrier between the aluminum and the concrete/masonry, preventing direct contact and minimizing the risk of galvanic corrosion. Additionally, using isolation materials such as gaskets or non-conductive joint fillers between the aluminum profiles and the concrete/masonry can further help to prevent galvanic corrosion by isolating the dissimilar metals. Regular inspection and maintenance are also essential to identify any potential corrosion issues early on and take necessary preventive measures.

- Q: Can aluminum profiles be used in the construction of stadium seating systems?

- Indeed, stadium seating systems can utilize aluminum profiles for their construction. Aluminum, being both lightweight and long-lasting, is frequently employed in a multitude of construction applications, including stadium seating systems. It presents numerous benefits, such as resistance to corrosion, a high strength-to-weight ratio, and ease of fabrication. By customizing and assembling aluminum profiles, seating structures that are sturdy, stable, and aesthetically pleasing can be easily created. Moreover, due to its lightweight nature, aluminum allows for simpler installation and transportation, making it a financially prudent choice for stadium seating systems. All in all, when considering their durability, versatility, and strength, aluminum profiles emerge as an appropriate selection for constructing stadium seating systems.

- Q: Excuse me, aluminum oxidation and electrophoresis have what different?

- Alumina:The substrate is used as an anode to be electrolyzed in an electrolyte, and a protective oxide film is formed on the surface of the substrate artificially so as to form an oxidized aluminum materialMain features of aluminium oxide material:1. It has strong wear resistance, weather resistance and corrosion resistance2, you can form a variety of colors on the substrate surface, the maximum to suit your requirements3, hardness is strong, suitable for all kinds of building, industrial material production

- Q: Can aluminum profiles be used for access control systems?

- Access control systems can utilize aluminum profiles, which are a versatile and durable material commonly used in construction and various industries. Aluminum offers an excellent strength-to-weight ratio and corrosion resistance, making it ideal for doors, frames, and enclosures. These profiles can easily accommodate locks, hinges, control panels, and readers. The lightweight nature of aluminum allows for easy installation and maintenance. Additionally, different coatings can be applied to enhance appearance and protect against harsh conditions. Customization is also possible, as aluminum profiles can be cut, drilled, and assembled to fit specific design requirements. Overall, aluminum profiles are a reliable and practical choice for securing access points.

- Q: What unique considerations or specifications are needed when utilizing aluminum profiles in cold weather conditions?

- <p>In cold climates, special requirements for using aluminum profiles include selecting materials with enhanced thermal performance to prevent condensation and frost. It's crucial to use aluminum profiles with appropriate thermal breaks to reduce heat loss. Additionally, consider using profiles with higher strength to withstand the contraction and expansion caused by temperature fluctuations. Protective coatings or finishes may be necessary to prevent corrosion from salt or other winter chemicals. Always consult with manufacturers for specific recommendations tailored to the climate conditions.</p>

- Q: Why should aluminum surface treatment process?

- He devotes himself to aluminum passivation, electroplating and surface treatment, and has problems to visit at any time.

- Q: What kind of equipment are needed for the production of aluminum profiles?

- The production of aluminum equipment not hundreds of several decades, from the beginning, homogeneous casting furnace, extrusion machine, anodic electrophoretic coating production line groove, powder powder production line, fluorocarbon paint production line, insulated aluminum production line, processing workshop welding riveting, stitching and other processing equipment. Plus to die do I still have, cars, milling, grinding, drilling, EDM, wire cutting, and other processing equipment. I am now in a small department work of aluminum processing company.

- Q: Is it possible to manufacture aluminum profiles in unique shapes or dimensions tailored for particular uses?

- <p>Yes, aluminum profiles can be made into custom shapes or sizes for specific applications. Manufacturers can customize aluminum profiles through various processes such as extrusion, cutting, bending, and machining to meet the unique requirements of different projects. This flexibility allows for the creation of specialized components that can be used in a wide range of industries, including construction, automotive, aerospace, and more.</p>

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 3 oxidation of metals: the periodic table clearly shows that magnesium alloy is more easily oxidized than aluminum alloy.4 manufacturing cost Description: because magnesium alloy is a lively metal, so manufacturing equipment and environment have higher requirements, leading to high manufacturing costs, production of bicycle frame cost performance is far less than aluminum alloy frame.

- Q: Are aluminum profiles recyclable?

- Yes, aluminum profiles are recyclable. Aluminum is a highly recyclable material, meaning it can be melted down and reused multiple times without losing its quality. Aluminum profiles, which are used in various applications such as construction, transportation, and manufacturing, can be easily recycled by collecting them from end-of-life products or scrap material and sending them to a recycling facility. The recycling process involves shredding the aluminum profiles into small pieces, removing any impurities, melting the aluminum, and then casting it into new profiles or other aluminum products. Recycling aluminum profiles helps to conserve natural resources, reduce energy consumption, and minimize environmental impact compared to producing new aluminum from raw materials.

Send your message to us

Aluminum Standard Industrial Aluminium Extrusion Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords