Glass Wool Insulation Fiberglass Insulation Blanket Manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 100000000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Insulation Manufacturers Glass wool

1.Structure of Glass Wool Insulation Manufacturers Glass wool:

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

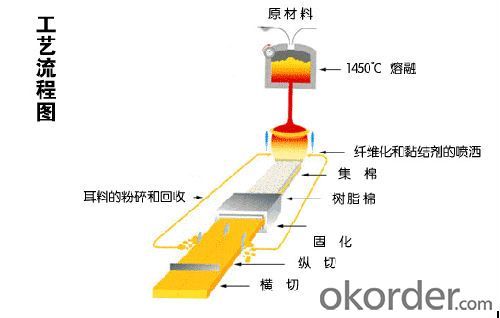

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Glass Wool Insulation Manufacturers Glass wool:

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

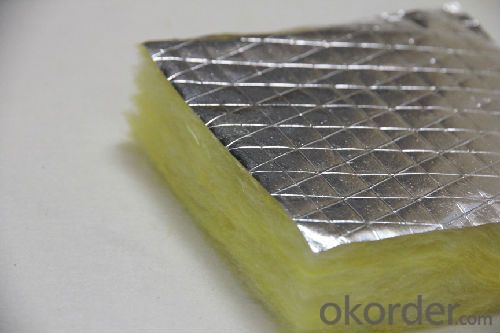

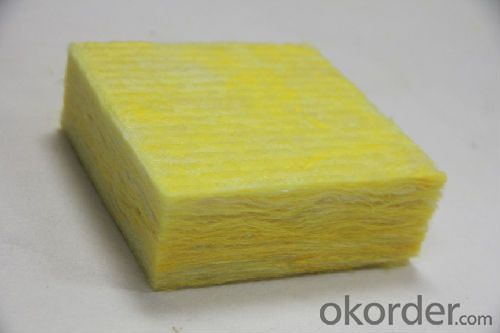

3. Glass Wool Insulation Manufacturers Glass wool Images

4. Glass Wool Insulation Manufacturers Glass wool Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

The glass wool product is placed in the glass of meltdown appearance proceed the fiber turn and spray the resin of solid that draw the hot silk wadding form material, then turn through hot solid the deep processing handles and can also make into the series and various products. Our glass wool felt is divided into bare felt and veneer rolled felt, which can effectively resist moisture, sound absorption, corrosion, and aesthetics. The surface layer is added to increase the product's breaking resistance, breakdown resistance, high tensile strength, beautiful appearance and simple construction.

- Q: What are the raw materials of centrifugal glass wool?

- The main raw materials of good centrifugal glass wools which are made of industrial chemicals like borax are natural ores like quartz sand, limestone, and dolomite, with some pure alkali.

- Q: Is the glass wool sound insulating? How good is it?

- Is it used on car?

- Q: Glass fiber, glass wool, what is the difference

- Glass wool is the fibrous glass fiber, the formation of cotton-like material, chemical composition of glass, is a kind of inorganic fiber. Has a good shape, small density, thermal conductivity, thermal insulation, sound-absorbing performance, corrosion resistance , Chemical stability.

- Q: What is the difference between the glass fiber and glass wool?

- Fiberglass is an excellent inorganic non-metallic material. There are many kinds of glass fibers whose advantages are good insulation, heat resistance, corrosion resistance, high mechanical strength, and the drawbacks are brittle and poor wear resistance. It is made from glass ball or wasted glass through high temperature melting, wire drawing, winding and weaving. The monofilament diameter is between several microns and dozens of microns, the same as 1 / 20-1 / 5 of a human hair. Each bunch of fibre precursor consists of hundreds of or even thousands of monofilaments. Glass fiber is usually used as reinforcing material of composite material, electric insulation material, thermal insulation material, circuit board and various areas. Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability.

- Q: Does anyone know about the filling materials in the steel stud, is it glass wool or mineral wool?

- They are very similar, both have advantages of fireproofness, sound and thermal insulation. While the glass wool has better sound insulation performance, and the rock wool has better fireproofness. The glass wool is white, and the rock wool is gray.

- Q: How effective is fireproofing glass fiber cotton?

- Fire-resistant glass fiber cotton is very good. More holes the fibers have, more breathable, warm, fluffy and soft it will be. This is because air is stored in holes. More holes it has, more air it will be. Moreover in the isolation layer, more air content it has, more permeable and thermal insulating it will be.

- Q: What is the difference between anti-high temperature glass wool and ordinary glass wool?

- Difference: High-temperature glass wool is made up of glass fibers and special high-temperature adhesive. It is yellowish with curing agent as the high temperature adhesive and with a small quantity of glue. While ordinary glass wool is dark yellow with ordinary resin adhesive as the binder.

- Q: What are the construction methods of glass?wool?board used in external wall?

- The phenomenon of moisture condensation in glass wool should be prevented.moisture condensation in glass wool, a layer of vapour barrier should be attached to the surface of the glass wool.A layer of glass wool should be fixed on the wall by insulation supporting pin prevent the glass wool from falling and thermal insulation properties from reducing.

- Q: Is centrifugal glass wool board suitable for home use?

- A large number of people think that glass wool boards are harmful and that it will cause itch when contacting with the skin. And the effect is not obvious used in the surface, so it is generally used in the wall sandwich. They are harmless for wool boards have been checked, and only those which have passed the national inspection are allowed to be sold for home use. But do not use it in the surface as it is fiber products.

- Q: How many types of centrifugal glass wool?

- Centrifugal glass wool board is centrifugal glass wool made by curing treatment after a certain strength plate products, whether in high or low temperature environment, it can maintain good thermal insulation and sound absorption properties, and it is mainly used for advanced architectural interior compartment, suspended ceiling, the thermal insulation of metal duct or wind box, studio room, machine room, etc. all are the noise reduction and absorption. the surface can paste PVC fabric membrane and can also paste aluminum foil. It has characteristics of a light capacity, sound absorption coefficient, flame retardant, excellent chemical stability.

Send your message to us

Glass Wool Insulation Fiberglass Insulation Blanket Manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 100000000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords