Custom Aluminum Extrusion Profiles for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

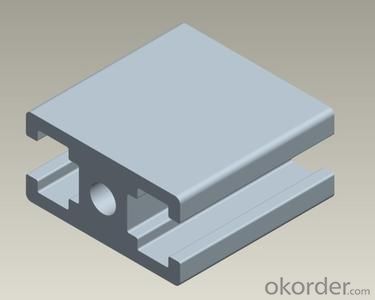

Aluminum Extrusion Profiles for Windows

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. Payment term?

Normally 30% TT, L/C at sight

2. Price trpy ?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: How do aluminum profiles contribute to lightweight construction?

- Due to their inherent properties and versatile applications, aluminum profiles play a crucial role in the field of lightweight construction. Firstly, aluminum, being a lightweight material, has a density that is roughly one-third of that of steel. This implies that using aluminum profiles instead of heavier materials like steel or concrete aids in minimizing the overall weight of the structure or product. The lightweight nature of aluminum profiles presents several advantages in the construction industry. One notable benefit is the ease of handling and installation, which reduces the reliance on heavy machinery and labor-intensive processes. Consequently, this not only enhances the efficiency of construction projects but also leads to cost reductions. Furthermore, the utilization of aluminum profiles in lightweight construction contributes to energy efficiency. Aluminum is an excellent conductor of heat and electricity, allowing for effective heat dissipation and decreased energy consumption in buildings. This property is particularly advantageous in the construction of energy-efficient buildings, aligning with sustainability objectives. Another aspect in which aluminum profiles contribute to lightweight construction is their exceptional strength-to-weight ratio. In spite of their lightweight nature, aluminum profiles possess high tensile strength, making them highly durable and capable of withstanding various loads and stresses. This characteristic enables the creation of robust and stable structures while minimizing the use of materials. Moreover, aluminum profiles offer design flexibility and versatility. They can be extruded into various shapes and sizes, empowering architects and designers to conceive intricate and innovative structures. The ability to customize profiles according to specific project requirements enhances the architectural possibilities in lightweight construction. Additionally, aluminum profiles exhibit corrosion resistance, significantly extending their lifespan and reducing maintenance costs. This makes them suitable for applications in diverse climates and environments, including coastal regions where saltwater corrosion is prevalent. In conclusion, aluminum profiles contribute to lightweight construction by reducing overall weight, enhancing energy efficiency, providing strength and durability, offering design flexibility, and ensuring corrosion resistance. These factors establish aluminum profiles as a preferred choice in a wide array of construction projects, ranging from residential buildings to large-scale infrastructure.

- Q: What are the standard dimensions of aluminum profiles?

- The specific industry and application can cause the standard dimensions of aluminum profiles to vary. Nevertheless, there are commonly available standard dimensions. Aluminum profiles are generally offered in a range of shapes and sizes, such as rectangular, square, circular, and customized shapes. Rectangular aluminum profiles typically have widths between 1 inch and 6 inches, and heights between 1/2 inch and 4 inches. Square profiles often have widths and heights ranging from 1 inch to 4 inches. Circular aluminum profiles, also referred to as tubes or pipes, usually come in different outer diameters, ranging from 1/4 inch to 8 inches, with wall thicknesses varying from 1/16 inch to 1/2 inch. It is important to note that these dimensions are general standards, and there may be variations depending on the manufacturer and specific project requirements. Additionally, custom dimensions can be manufactured to meet unique specifications. To ensure the chosen dimensions can adequately support the intended use, it is crucial to consider the intended application and load-bearing requirements when selecting aluminum profiles.

- Q: What are the different shapes available for aluminum profiles?

- There are various shapes available for aluminum profiles, each designed to suit different applications and requirements. Some commonly used shapes include: 1. T-Slot profiles: These profiles have a T-shaped cross-section, with slots on one or more sides. They are widely used in construction, robotics, and industrial applications, as they allow for easy assembly and integration of other components. 2. Square profiles: These profiles have a square-shaped cross-section and are often used for structural applications. They provide excellent strength and rigidity, making them suitable for building frames, machine bases, and support structures. 3. Rectangular profiles: Similar to square profiles, rectangular profiles have a rectangular-shaped cross-section. They offer versatility and can be used in a wide range of applications, including enclosures, partitions, and conveyor systems. 4. Round profiles: These profiles have a circular cross-section and are commonly used in applications that require a smooth and aesthetically pleasing finish. They are often used for architectural purposes, such as handrails, furniture, and decorative elements. 5. L-Shaped profiles: L-shaped profiles have a 90-degree angle and are often used for corner joints, edges, and brackets. They provide structural support and stability and are commonly used in construction and manufacturing industries. 6. U-Shaped profiles: U-shaped profiles have a U-shaped cross-section, resembling an open channel. They are frequently used in applications that require a protective housing or a channel to guide cables, wires, or other components. 7. Custom profiles: Apart from the standard shapes mentioned above, aluminum profiles can also be custom-designed and manufactured to meet specific project requirements. This allows for greater flexibility and ensures the aluminum profiles perfectly fit the intended application. Overall, the availability of different shapes for aluminum profiles enables engineers, designers, and manufacturers to select the most appropriate shape for their specific needs, ensuring optimal performance, functionality, and aesthetics.

- Q: What are the applications of aluminum profiles?

- Due to their unique characteristics and properties, aluminum profiles have a wide range of applications in various industries. Some of the main uses of aluminum profiles are as follows: 1. In the construction industry, aluminum profiles are extensively employed for windows, doors, curtain walls, and structural components. Their excellent strength, durability, and corrosion resistance make them ideal for building purposes. 2. The automotive industry utilizes aluminum profiles to manufacture lightweight and fuel-efficient vehicles. They are used in the production of car frames, engine mounts, heat exchangers, and other structural components. 3. The aerospace industry relies on aluminum profiles for their high strength-to-weight ratio. They are used in the construction of aircraft frames, wings, fuselage, and other critical components. 4. Aluminum profiles are widely used in electrical and electronics applications. Their excellent thermal conductivity and electrical insulation properties make them suitable for manufacturing heat sinks, LED lighting fixtures, electrical enclosures, and electronic device housings. 5. The furniture industry is increasingly incorporating aluminum profiles to create lightweight and stylish furniture pieces. They are used in the production of chairs, tables, cabinets, and shelving systems, providing a modern and aesthetic appeal. 6. Aluminum profiles play a significant role in the manufacturing of industrial machinery and equipment. They are utilized in the construction of conveyor systems, assembly line structures, machine frames, and guarding systems due to their lightweight, durability, and ease of fabrication. 7. In the marine industry, aluminum profiles are commonly used for their corrosion resistance and lightweight properties. They are utilized in the construction of boat frames, masts, hulls, and other marine structures. 8. Aluminum profiles also find applications in renewable energy systems such as solar panels and wind turbines. They are used in the manufacturing of solar panel frames, wind turbine supports, and mounting structures due to their lightweight nature and corrosion resistance. Overall, aluminum profiles offer a versatile and cost-effective solution for various industries, meeting their specific requirements for strength, durability, lightweight, and corrosion resistance.

- Q: Can aluminum profiles be used for furniture?

- Yes, aluminum profiles can be used for furniture. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications such as tables, chairs, and frames. It offers versatility in design, allowing for sleek and modern aesthetics. Additionally, aluminum profiles can be easily customized and are available in different finishes, making them a popular choice in the furniture industry.

- Q: Can aluminum profiles be subjected to painting or coating processes to improve their aesthetic appeal and resistance to wear?

- <p>Yes, aluminum profiles can be painted or coated. This process not only enhances their appearance but also significantly improves their durability and resistance to corrosion. Aluminum has a natural oxide layer that provides some protection, but painting or coating can offer additional layers of defense against environmental factors. These coatings can be applied through various methods such as powder coating, anodizing, or electrophoretic deposition, each providing a different finish and level of protection. The choice of coating depends on the specific requirements for appearance, performance, and the environment in which the aluminum profile will be used.</p>

- Q: What are the regulations and standards that govern the use of aluminum profiles in construction?

- <p>Yes, there are several regulations and standards related to the use of aluminum profiles in construction. These include international standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. Additionally, regional standards like the European EN 755 for extruded aluminum alloys and the American Architectural Manufacturers Association (AAMA) standards for aluminum products in buildings are crucial. Compliance with these standards ensures the safety, durability, and performance of aluminum profiles in construction applications.</p>

- Q: What are the electrical insulation properties of aluminum profiles?

- Aluminum profiles have relatively low electrical insulation properties compared to other materials commonly used in electrical applications, such as plastics or ceramics. This is because aluminum is a highly conductive material, meaning it readily allows the flow of electrical current. However, aluminum profiles can still be used effectively in electrical applications if proper precautions are taken to ensure insulation. For example, aluminum profiles can be anodized or coated with insulating materials such as epoxy or polyurethane to improve their insulation properties. These coatings create a barrier between the aluminum and the electrical current, reducing the risk of electrical conductivity. Additionally, aluminum profiles can be used in conjunction with other insulating materials to provide the desired level of electrical insulation. For example, when used in electrical wiring systems, aluminum conductors are often combined with insulating materials such as PVC or cross-linked polyethylene to provide reliable insulation. It is important to note that while aluminum profiles may have lower electrical insulation properties compared to other materials, they do offer other desirable characteristics such as high strength, lightweight, and corrosion resistance. Therefore, careful consideration should be given to the specific application and electrical requirements before selecting aluminum profiles as an electrical insulation material.

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the construction of commercial buildings.

- <p>Commonly used aluminum profiles in commercial buildings include: 1. Extruded aluminum profiles, which are versatile and used for window frames, door frames, and curtain walls. 2. Structural aluminum profiles, used for load-bearing structures and support systems. 3. Architectural aluminum profiles, designed for aesthetic and functional purposes like facades and decorative elements. 4. Industrial aluminum profiles, used in manufacturing and assembly lines. 5. Thermal break aluminum profiles, which reduce heat transfer and are used in energy-efficient buildings. 6. Anodized aluminum profiles, offering enhanced durability and corrosion resistance. These profiles are chosen based on specific project requirements, such as structural needs, design aesthetics, and environmental considerations.</p>

Send your message to us

Custom Aluminum Extrusion Profiles for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords