Industrial Aluminum Profiles for Honda Spare Parts Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Extrusion For Honda Spare PartsDescription:

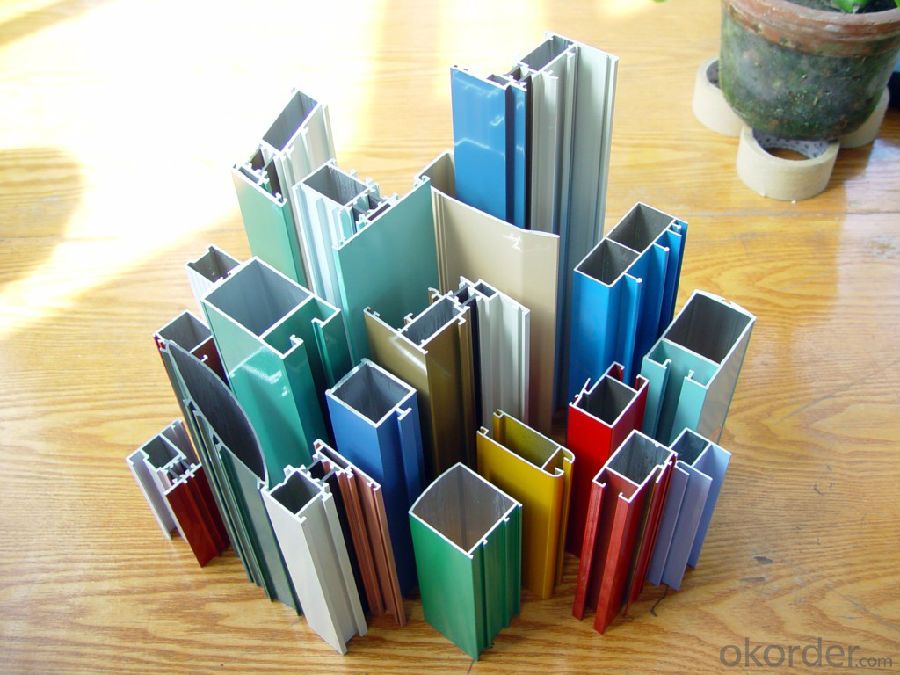

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Extrusion For Honda Spare PartsDescription:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

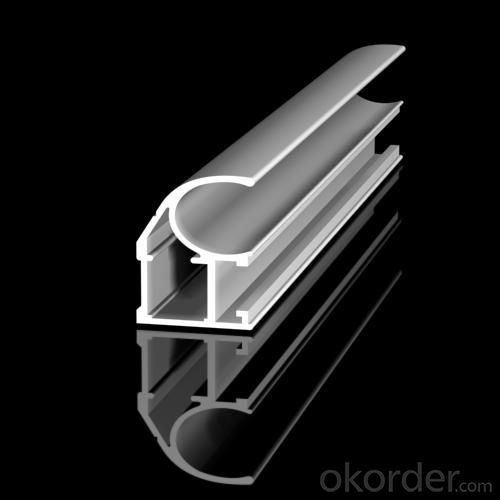

Images of the Aluminium Extrusion For Honda Spare Parts:

Aluminium Extrusion For Honda Spare Parts Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: This question asks about the various types of aluminum profiles that are utilized in the construction of insulation systems.

- <p>Aluminum profiles used for building insulation come in various types, each serving specific functions. These include: 1. Insulation profiles, which provide a thermal barrier; 2. Structural profiles, used for structural support; 3. Cover profiles, which protect the insulation material; 4. Joint profiles, used for sealing joints; 5. Corner profiles, for reinforcing corners; 6. Edge profiles, for finishing edges; and 7. Special profiles, designed for specific applications. Each type is engineered to enhance thermal efficiency and structural integrity in building insulation systems.</p>

- Q: What are the different alloys available for aluminum profiles?

- There are several different alloys available for aluminum profiles, each with its own unique properties and characteristics. Some commonly used alloys include: 1. 6061-T6: This is one of the most widely used alloys for aluminum profiles. It offers excellent strength, corrosion resistance, and weldability. It is often used in structural applications such as frames, beams, and supports. 2. 6063-T5: This alloy is known for its good formability and extrudability, making it ideal for creating complex shapes and designs. It has good corrosion resistance and is often used in architectural applications, such as window frames and curtain walls. 3. 7075-T6: This alloy offers high strength and toughness, making it suitable for applications that require exceptional strength, such as aerospace components and high-stress structural parts. 4. 6082-T6: This alloy is similar to 6061-T6 in terms of strength and corrosion resistance, but it offers better machinability. It is commonly used in automotive and transportation industries. 5. 3003-H14: This alloy is primarily used for its excellent resistance to corrosion. It is often used in marine applications, as well as in chemical and food processing industries. These are just a few examples of the many alloys available for aluminum profiles. The choice of alloy depends on the specific requirements of the application, such as strength, corrosion resistance, formability, and machinability.

- Q: Aluminum prices are calculated by the meter, or how to quote the ah?

- The normal price is according to the tonnage, converted 1 kilo yuan, also hit the idea of calculation, according to the profile rate multiplied by the current ratio, such as a 6m profile, price of 400 yuan, the current ratio of 0.4, the price is 160 yuan each.

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: Is it possible to use aluminum profiles for outdoor applications like fences and railings?

- <p>Yes, aluminum profiles are commonly used for outdoor applications such as fences and railings. They are favored for their resistance to corrosion, lightweight properties, and durability. Aluminum can withstand harsh weather conditions without rusting, making it an ideal material for outdoor use. Additionally, it is low maintenance, as it does not require painting or frequent repairs. The profiles can be powder-coated or anodized for enhanced protection and aesthetic appeal.</p>

- Q: This question is asking about the various types of aluminum profiles that are used for exterior cladding purposes.

- <p>Aluminum profiles for exterior cladding are diverse and serve various architectural and functional needs. Some common types include: 1. Flat Profiles: Used for simple, sleek designs. 2. Box Profiles: Ideal for creating a modern, industrial look. 3. Angle Profiles: Useful for corners and edges. 4. Channel Profiles: Often used for window and door frames. 5. T-Profiles: Commonly used for hidden fastening systems. 6. U-Channels: Suitable for cover applications. 7. Special Profiles: Custom designs for specific architectural requirements. Each type offers unique benefits in terms of aesthetics, strength, and weather resistance, making them suitable for different building facades and exterior applications.</p>

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Aluminum does not have the corresponding market basically, basically in Nanjing to do a relatively large Nanjing Meida aluminum, Nanjing Heng aluminium, yum Nanjing aluminum, Nanjing to build up the aluminum industry, basically is the nature of the company, you can go directly to their website to search their own needs aluminum.

- Q: Explain if aluminum profiles can be utilized in constructing energy-efficient building systems and if so, how they contribute to energy efficiency.

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight yet strong, which reduces the energy required for construction. Aluminum profiles also have excellent thermal conductivity, allowing them to be used in double-glazed windows and doors, improving insulation and reducing heat loss. Additionally, aluminum can be easily recycled, reducing the energy needed for new materials. Their high reflectivity can also help in reducing heat absorption, further contributing to energy efficiency.</p>

- Q: Can aluminum profiles be used for partitions and dividers?

- Partitions and dividers can indeed be made using aluminum profiles. This material is highly versatile, being lightweight, long-lasting, and resistant to corrosion. Therefore, it is an ideal option for applications like these. With aluminum profiles, it is effortless to fabricate and personalize different designs for partitions and dividers. Whether it is room dividers, office partitions, or retail space separators, the possibilities are endless. Moreover, these profiles can be used in both residential and commercial environments to create practical and visually appealing spaces. Additionally, opting for aluminum profiles ensures convenient installation, maintenance, and potential modifications in the future.

- Q: Is it possible to manufacture aluminum profiles in unique shapes or dimensions tailored for particular uses?

- <p>Yes, aluminum profiles can be made into custom shapes or sizes for specific applications. Manufacturers can customize aluminum profiles through various processes such as extrusion, cutting, bending, and machining to meet the unique requirements of different projects. This flexibility allows for the creation of specialized components that can be used in a wide range of industries, including construction, automotive, aerospace, and more.</p>

Send your message to us

Industrial Aluminum Profiles for Honda Spare Parts Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords