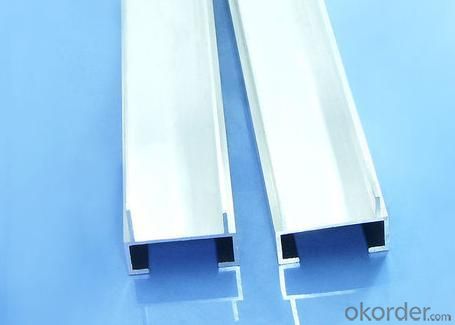

Aircraft Aluminum Extrusion Profiles for Industry

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of aluminium Profile for Industry

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of aluminium Profile for Industry

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

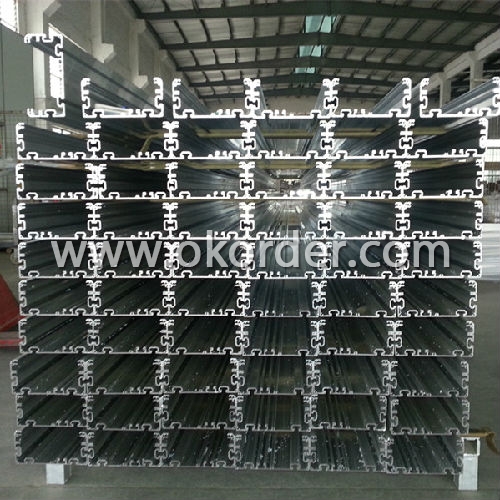

3 Packaging & Delivery of aluminium Profile for Industry

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of aluminium Profile for Industry

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: How do you install aluminum profiles?

- Follow these instructions for installing aluminum profiles: 1. Begin by measuring and cutting the profiles to the desired length using a saw equipped with a fine-tooth blade. It is essential to wear safety goggles and gloves during the cutting process. 2. Prior to installation, ensure the surface where the profiles will be placed is thoroughly cleaned. Remove any dirt, dust, or debris that could interfere with the installation. 3. Apply adhesive or silicone sealant to the back of the profile to securely attach it to the surface and create a watertight seal. 4. Position the profile on the surface and firmly press it down to guarantee proper adhesion. Utilize a level to ensure it is straight and correctly aligned. 5. If needed, utilize screws or fasteners to further secure the profile to the surface. Pre-drill pilot holes to prevent any cracking of the aluminum. 6. Repeat this process for each profile, leaving a small gap between them to account for expansion and contraction. 7. Once all profiles are installed, remove any excess adhesive or sealant. Use a damp cloth or sponge to wipe away any residue. 8. Allow the profiles to fully cure according to the manufacturer's instructions before applying any additional finishes or utilizing the area. Always consult the manufacturer's instructions for specific installation guidelines and recommendations.

- Q: You know, aluminum radiator, why should aluminum do?

- The biggest difference of aluminum radiator is that it has good corrosion resistance. Is due to the use of aluminum, it has the characteristics of corrosion resistance, because after aluminum in contact with oxygen, the aluminum surface to form a layer of oxide film, this layer of film to corrosion effect on the corrosion of an object. So, it's very good corrosion resistance.

- Q: What tests do the aluminum profiles used in the curtain wall project do?

- Aluminum alloy material3.2.1 glass curtain wall by chemical composition corresponding to Aluminum Alloy material grades should be consistent with current national standard "the relevant provisions of the chemical composition" deformation of aluminum and Aluminum Alloy GB / T 3190, the quality of Aluminum Alloy section shall comply with the provisions of the current national standard "Aluminum Alloy architecture" GB / T 5237, section size deviation should be allowed to high grade or ultra high grade.3.2.2 Aluminum Alloy profiles by anodic oxidation, electrophoretic coating, powder coating, fluorocarbon paint spraying surface treatment, quality should be consistent with current national standard "Aluminum Alloy architecture" GB / T 5237 requirements, the thickness of surface layer should meet the requirements in table 3.2.2.3.2.3 insulated aluminum profiles produced by the strip process shall be made of PA66GF25 (polyamide 66+25 glass fiber) material and shall not be made of PVC material. A heat insulated aluminum profile produced by pouring process shall be made of PUR (polyurethane) material. The shear strength of the joint must meet the design requirements.3.2.4 and glass curtain wall matching aluminum alloy doors and windows should comply with the current national standard "aluminum alloy door", GB / T 8478 and aluminum alloy window "GB/T 8479" provisions.

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: Including the element parameters, the price and the difference between 6063, what is the use and so on!How about 6060 100/ meters? How much is the strength? How much is the price more than 6063?

- 6060 aluminum material compositionSi:0.3-0.6, Fe:0.1-0.3, Cu:0.1, Mn:0.1, Mg:0.35-0.6, Cr:--, Zn:0.1, others:Ti:0.15 other total: 0.15 Al: marginPerformance: tensile strength B (MPa): more than 470 conditions yield strength of 0.2 (MPa): more than 420 elongation 5 (%): 6Product features: 1. high strength, heat treatable alloy.2., good mechanical properties,.3. good usability,.4. easy processing, good wear resistance,.5. corrosion resistance, good oxidation resistanceMain uses: Aviation fixtures, truck, tower building, ships, pipelines and other applications requiring strength, weldability and corrosion resistance of the building on the field. Such as: aircraft parts, camera lens, coupler, ship fittings and accessories, electronic accessories and fittings, decoration or various hardware, hinge head head, piston, piston, hydraulic brake, electric appliance fittings, valves and valve parts.6063 aluminum chemical composition:Al Al: residual silicon Si:0.20 ~ 0.6 copper Cu: less than 0.10 mg Mg:0.45 ~ 0.9 zinc Zn: Mn: Mn = 0.10 = 0.10 Ti = 0.10 Cr: titanium chromium iron: less than or equal to 0.10 Fe:0.000 ~ 0.350 note: single: = 0.05; total: 0.15The density of 6063 is 2.69g/cm3

- Q: This question asks for a comparison between aluminum profiles and other materials used in constructing frames, focusing on their characteristics and performance.

- <p>Aluminum profiles are favored for building frames due to their high strength-to-weight ratio, making them lightweight yet durable. They offer excellent corrosion resistance, which is superior to materials like steel, which can rust. Aluminum profiles are also easy to machine and form, allowing for complex designs. Compared to wood, they are more resistant to weathering and pests. However, they may not have the same aesthetic appeal as wood or the thermal insulation properties of some plastics. Overall, aluminum profiles are a strong choice for structural integrity and longevity in frame construction.</p>

- Q: Aluminum profiles and plastic doors and windows which good, what market?

- Always feel that aluminum is better to do it?! As far as I know, aluminum is more wear resistant, more resistant to corrosion, and it is not easily deformed. There is an aluminum company in Shanghai. I think it's not bad. I bought it there several times. This is what my family uses

- Q: Can aluminum profiles be an alternative to wood in construction?

- Yes, aluminum profiles can certainly be a viable alternative to wood in construction. Aluminum is lightweight, durable, and resistant to rust and corrosion, making it an excellent choice for various construction applications. Additionally, aluminum profiles offer flexibility in design, are easy to install, and require minimal maintenance. They can be used for structural components, windows, doors, cladding, and other construction elements, providing a sustainable and cost-effective solution compared to wood.

- Q: Are aluminum profiles energy-efficient?

- Yes, aluminum profiles are considered to be energy-efficient. Aluminum is a highly conductive material, which means it can effectively transfer heat or cold. This property allows aluminum profiles to provide excellent thermal insulation, helping to minimize energy loss and maintain a consistent indoor temperature. Additionally, aluminum profiles can be designed with thermal breaks, which further enhance their energy efficiency by reducing heat transfer between the inside and outside of a building. These features make aluminum profiles a popular choice for windows, doors, and other building components, as they contribute to energy savings and reduce the overall carbon footprint of a structure.

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 5 specific gravity density: under the same volume conditions, magnesium alloy is lighter than aluminum alloy, which is the advantage of magnesium alloy.6 modulus of elasticity: the frame made of magnesium alloy is more rigid than aluminum alloy frame, and the frame made of the same thickness and caliber can absorb more trampling force when riding, which will influence riding efficiency.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aircraft Aluminum Extrusion Profiles for Industry

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords