Aluminum Foil Facing Breathable Membrane with Breather Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The breathable membrane is thermally laminated using a high-polymer material in its middle layer. When laid on top of an insulation system, it not only enhances the building's water tightness but also eliminates humidity within the enclosure through its unique breathability. This effectively prolongs the building's lifespan and contributes to thermal insulation, energy conservation, and an improved living environment.

Advantages:

They offer excellent water resistance, protecting against moisture and potential leaks.

They possess a unique vapor permeability.

They are tear-resistant, wear-resistant, and possess good extensibility, ensuring durability and flexibility.

They are lightweight, thin, and antiskid, with good low-temperature flexibility, making them suitable for construction in various conditions.

They are made from 100% recyclable polymer materials, aligning with ecological requirements and promoting sustainability.

Applications:

Roofing: Used under roofing materials like tiles or shingles to enhance waterproofing and ventilation.

Walls: Applied behind cladding to manage moisture and maintain structural integrity.

Timber Frame Construction: Integrated to prevent moisture buildup in timber frame buildings.

Flooring: Used to prevent rising damp in ground or timber floors.

Facade Construction: Enhances insulation and weather protection while allowing breathability in ventilated facades.

Industrial Use: Controls moisture in warehouses, factories, and agricultural buildings.

Improves energy efficiency and moisture control in retrofit projects.

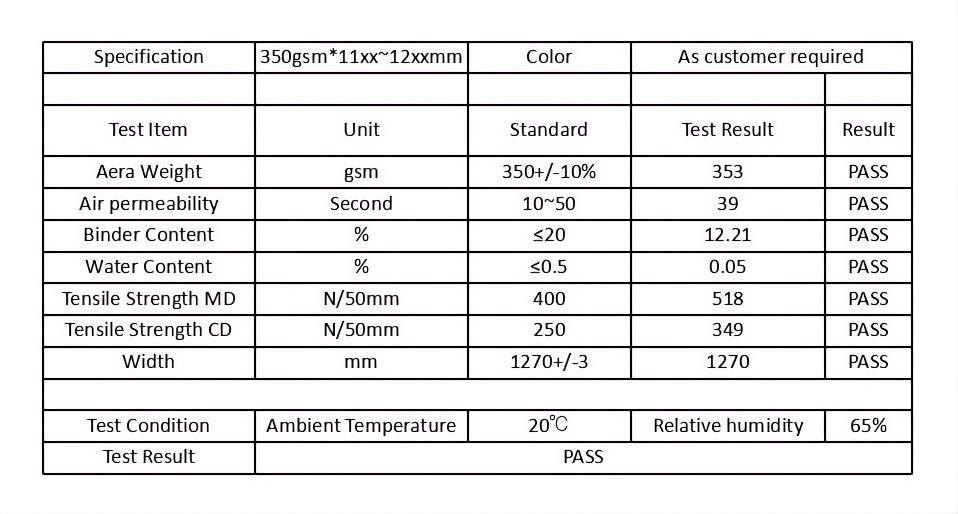

Parameter:

Cost Analysis:

Initial Cost:

Price Range: The cost of breathable membranes varies based on material, thickness, and brand.Factors Affecting Cost: Material quality, thickness, and additional features like UV resistance.

Maintenance Costs:

Long-term Savings: Reduces expenses by preventing issues such as moisture damage and mold growth.

Durability: High-quality membranes require less frequent replacement or repair.

Return on Investment:

Energy Savings: Improved insulation can reduce heating and cooling costs, leading to significant energy savings.

Property Value: Enhanced building performance can increase property value and marketability.

Cost Comparison:

Traditional Moisture Barriers: Lower initial cost but higher long-term maintenance and energy costs.

Breathable Membranes: Higher initial investment but greater overall savings and benefits in the long run.

Market Trends:

Current Use:

Overview: Widely used in residential, commercial, and industrial construction for moisture control and energy efficiency.

Popularity: Increasingly popular in green building projects and sustainable construction practices.

Technological Innovations:

New Materials: Advances in polymer science have led to more durable and efficient breathable membranes.

Smart Sensors: Integration of sensors to monitor moisture levels and structural conditions in real-time.

Self-healing Coatings: Development of membranes with self-repairing capabilities to extend lifespan and reduce maintenance.

Growth Projections:

Market Forecasts: Expected to grow significantly, driven by increasing demand for energy-efficient and sustainable building materials.

Emerging Markets: Growth opportunities in regions with extreme climates, where moisture control and insulation are critical.

Emerging Applications:

Automotive: Use in vehicle manufacturing for moisture control and thermal management.

Sports Facilities: Applications in sports arenas and leisure centers to manage humidity and enhance comfort.

New Construction Methods: Adaptation to modern construction techniques such as modular and prefabricated building systems.

- Q: Is it possible for aluminum foil facing to induce allergic reactions in certain individuals?

- <p>Yes, aluminum foil facing can cause allergic reactions in some people. Aluminum is a common allergen, and individuals with a sensitivity to it may experience contact dermatitis or other allergic responses when exposed to aluminum-containing products. Symptoms can include redness, itching, and rashes. People with a known allergy to aluminum should avoid direct skin contact with aluminum foil and products containing aluminum.</p>

- Q: Is it possible to use aluminum foil with a reflective side to wrap sandwiches?

- <p>Yes, you can use aluminum foil facing to make sandwiches. The reflective side of aluminum foil is food-safe and can be used to wrap sandwiches for storage or transportation. It helps to keep the sandwich fresh and prevents it from drying out. However, it's important to ensure the foil is clean and free from any sharp edges that might tear the bread or packaging. Additionally, it's best to avoid using foil with non-stick coatings on the inside when in contact with food.</p>

- Q: Describe the most effective method for folding aluminum foil edges to seal food packaging.

- <p>The best way to fold aluminum foil facing for food packaging involves a few simple steps. Start by placing the food in the center of the foil. Bring two opposite edges of the foil together over the food, ensuring they overlap slightly. Fold one edge over the other, creating a seam. Press down firmly to seal. Repeat this process with the remaining two edges, ensuring all edges are sealed tightly. For added security, you can fold the edges inward to create a double seam. This method prevents leakage and keeps the food fresh and protected during cooking or storage.</p>

- Q: Is it possible to use aluminum foil with a facing layer to wrap sandwiches?

- <p>Yes, aluminum foil facing can be used to wrap sandwiches. It provides a barrier to keep the sandwich fresh and protected. However, it's important to ensure that the facing layer is food-safe and doesn't contain any harmful substances that could leach into the food. Always check the packaging to confirm that the aluminum foil is suitable for food contact.</p>

- Q: This question asks for a method to clean aluminum foil after cooking to get rid of excess oil.

- <p>To remove excess oil from aluminum foil after cooking, first let the foil cool down to avoid burns. Then, you can use a paper towel or a clean cloth to gently wipe away the oil. For stubborn oil, you can wash the foil with warm soapy water. If you're reusing the foil, make sure it's thoroughly dried before storing to prevent any potential for bacterial growth. Always remember to handle aluminum foil with care as it can be sharp and may tear easily.</p>

- Q: What are some lesser-known applications of aluminum foil in the kitchen?

- <p>Aluminum foil facing has several creative uses in the kitchen beyond just wrapping food. It can be used to cover baking dishes to prevent spills and messes in the oven, line baking sheets for easy cleanup, or create a makeshift roasting bag for cooking meats. It can also be used to sharpen knives by folding it into a book shape and running the blade through the sharp edges, or to create a non-stick surface for cooking by lining molds or baking pans. Additionally, it can be used to scrub pots and pans, removing stuck-on food, or to create a barrier between food and direct heat to prevent burning. These uses showcase the versatility of aluminum foil in the kitchen.</p>

- Q: Is it safe to use pre-cut sheets of aluminum foil for cooking or baking purposes?

- <p>Yes, it is generally safe to use pre-cut sheets of aluminum foil for cooking and baking. Aluminum foil is designed to withstand high temperatures and is commonly used to cover food, line baking sheets, or wrap food for cooking. However, it's important to ensure that the foil does not come into direct contact with the heating element of an oven, as this can cause it to melt or create a fire hazard. Additionally, avoid using aluminum foil with non-stick cookware, as it can damage the non-stick surface. Always follow the manufacturer's guidelines for safe use of aluminum foil in your specific cooking appliances.</p>

- Q: This question asks whether glass or ceramic containers are preferable for storing food over plastic or metal containers.

- <p>Glass and ceramic containers are often considered better for storing food due to their non-porous nature, which prevents the absorption of flavors and potential leaching of chemicals. Glass is generally safe for storing both acidic and alkaline foods, while ceramic containers should be checked for lead-based glazes, especially for acidic foods. Plastic containers can leach chemicals over time, and metal containers may react with certain foods, affecting taste or safety. However, the choice also depends on factors like the type of food, storage duration, and personal preference.</p>

- Q: What are the methods to prevent food from sticking to the aluminum foil surface during cooking?

- <p>To prevent food from sticking to the surface of aluminum foil when cooking, you can use a few techniques. First, lightly coat the foil with a thin layer of oil or non-stick cooking spray. This creates a barrier that food won't stick to. Second, ensure that the foil is smooth and wrinkle-free; any rough spots can cause food to stick. Additionally, avoid overfilling the foil as this can lead to uneven cooking and sticking. Finally, consider using parchment paper or a silicone baking mat instead of foil for some foods, as they can provide a non-stick surface without the risk of aluminum foil tearing or food sticking.</p>

- Q: Is it safe to use aluminum foil facing to wrap vegetables or fruits for roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables or fruits before roasting or grilling. Aluminum foil is a common and safe method for cooking food as it retains moisture and heat, allowing for even cooking. However, ensure that the foil does not come into direct contact with the heat source for extended periods to avoid any potential risk of aluminum leaching into the food. It's also important to use heavy-duty aluminum foil for cooking to prevent tearing or puncturing during the cooking process.</p>

Send your message to us

Aluminum Foil Facing Breathable Membrane with Breather Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords