Extruded Rubber Seals

Extruded Rubber Seals Related Searches

Automotive Rubber Seals Extruded Aluminum Beams Extruded Plastic Profiles Aluminum Extruded Tubing Extruded Aluminum Rail Aluminum Extrusions Rubber Clamps Waterproof Seal Rubber Coupling Extruded Aluminum Heatsink Extruded Aluminum Track Extruded Polystyrene Foam Rubber Bonded Grinding Wheels Waterproof Sealer Rubber Tube Fittings Expanded Plastic Mesh Extruded Polystyrene Xps Plastic Extrusion Profiles Exterior Rigid Foam Insulation Aluminum Extrusion Shapes Roofing Sealer Roof Sealer Transparent Rubber Tube Corrugated Roof Sealant Ev Charging Connector Seal Aluminium Extrusion Expanded Polystyrene Insulation Sheets Extruded Polystyrene Thermal Conductivity Extruded Polystyrene Foam Board Aluminum Sealing TapeExtruded Rubber Seals Supplier & Manufacturer from China

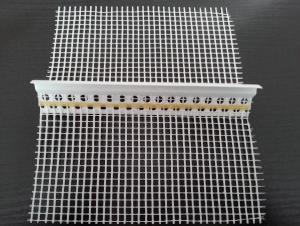

Extuded Rubber Seals are a type of sealing product made from rubber that is extruded into various shapes and sizes. These seals are designed to provide a reliable barrier against the passage of fluids, gases, or other substances, and are commonly used in a wide range of industries due to their excellent sealing properties. They are available in various materials, such as EPDM, silicone, and neoprene, to cater to different applications and environments.Extuded Rubber Seals are widely used in automotive, aerospace, construction, and industrial applications, where they are employed to seal doors, windows, machinery, and various other equipment. These seals can be found in a variety of usage scenarios, such as preventing water ingress in vehicles, maintaining airtight seals in pressurized systems, and providing a barrier against dust and debris in machinery. Their flexibility and durability make them an ideal choice for many sealing applications, ensuring long-lasting performance and reliability.

Okorder.com is a leading wholesale supplier of Extruded Rubber Seals, offering a vast inventory of these products to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that their seals meet the highest standards of performance and durability. By providing a comprehensive range of Extruded Rubber Seals, Okorder.com is able to serve a diverse clientele, from small businesses to large corporations, and help them find the perfect sealing solution for their specific requirements.

Hot Products