Aluminium Extrusion Profiles For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

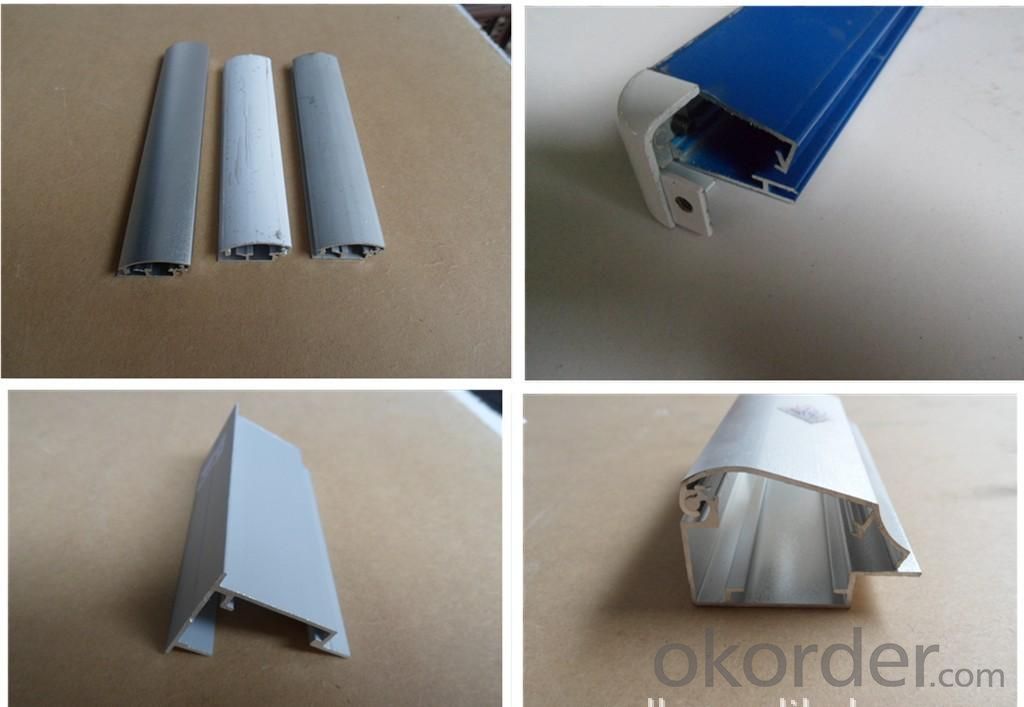

Product Name | Aluminium Extrusion Profiles For Construction |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: How do aluminum profiles contribute to energy-efficient lighting systems?

- Aluminum profiles play a significant role in enhancing the energy efficiency of lighting systems. Firstly, aluminum is a lightweight and highly conductive material, allowing for efficient heat dissipation. This is crucial in lighting systems as excessive heat can reduce the lifespan and efficiency of the bulbs. By using aluminum profiles, the heat generated by the light source can be effectively transferred away, ensuring optimal performance and longevity. Furthermore, aluminum profiles are versatile and can be designed to accommodate various lighting components such as LED strips or bulbs, reflectors, and lenses. These profiles provide a stable and secure housing for these components, preventing any damage or misalignment that could impact the efficiency of the lighting system. Additionally, aluminum profiles often feature precision engineering, allowing for easy installation and maintenance, further contributing to the overall energy efficiency of the system. Another key advantage of aluminum profiles is their ability to act as a heat sink. By directing heat away from the light source, the profiles help to maintain lower operating temperatures, reducing energy consumption and increasing the efficiency of the lighting system. This is particularly important for LED lighting, as they are highly sensitive to heat and can experience significant light output degradation if not properly cooled. Aluminum profiles enable efficient thermal management, ensuring that the LED lights operate at their optimum level, saving energy and reducing the need for frequent replacements. Moreover, aluminum is a recyclable material, making it an environmentally friendly choice for lighting systems. Using aluminum profiles promotes sustainable practices by reducing the demand for raw materials and minimizing waste. This aligns with the principles of energy efficiency and conservation, as it reduces the overall carbon footprint of the lighting system. In summary, aluminum profiles contribute to energy-efficient lighting systems by facilitating effective heat dissipation, providing a stable housing for lighting components, acting as a heat sink, and promoting sustainable practices. These profiles enhance the performance, lifespan, and energy efficiency of lighting systems, making them an essential component in modern lighting solutions.

- Q: Can aluminum profiles be used in curtain wall systems?

- Indeed, curtain wall systems have the capacity to incorporate aluminum profiles. Such systems usually consist of lightweight materials that provide structural support while simultaneously permitting ample natural light to infiltrate a building. The utilization of aluminum in curtain wall systems is quite prevalent owing to its robustness, endurance, and versatility. Aluminum showcases exceptional resistance against corrosion, rendering it suitable for outdoor applications. Furthermore, aluminum profiles can be readily fabricated into diverse shapes and sizes, thus enabling flexibility in design and assembly. The lightweight nature of aluminum also facilitates easier and more cost-effective installation. In summary, aluminum profiles offer an optimal solution for curtain wall systems, delivering both aesthetic allure and functional efficacy.

- Q: How do aluminum profiles contribute to the reduction of noise pollution?

- Noise pollution can be reduced in various ways with the use of aluminum profiles. To begin with, aluminum, being a lightweight material, is ideal for constructing windows and doors that have excellent sound insulation properties. These profiles are effective in blocking and absorbing sound waves, thereby preventing the transmission of outside noise into indoor spaces and vice versa. Furthermore, the durability of aluminum profiles ensures that their sound insulation capabilities remain effective over time. Unlike other materials, aluminum does not easily warp or degrade, allowing it to consistently serve as a barrier against noise pollution. Moreover, manufacturers can enhance the noise reduction capabilities of aluminum profiles by incorporating special features. For instance, rubber or foam seals can be added to create an airtight seal when windows or doors are closed, further minimizing sound transmission. This effectively blocks external noise, resulting in a quieter and more peaceful indoor environment. Additionally, aluminum profiles offer customization options to meet specific requirements and noise reduction needs. They can be designed with multiple layers of glass, each with different thicknesses and acoustic properties, to provide even higher levels of sound insulation. This versatility allows for tailored solutions to address different levels of noise pollution, making aluminum profiles a suitable choice for noise reduction. In conclusion, aluminum profiles contribute to reducing noise pollution through their lightweight and durable construction, sound insulation properties, and customization options. By blocking and absorbing sound waves, these profiles create a quieter indoor environment, ultimately improving the comfort and quality of life for individuals in residential and commercial settings.

- Q: Can aluminum profiles be used for agricultural or farming applications?

- Indeed, agricultural or farming applications can make use of aluminum profiles. They possess several advantages that make them appropriate for these purposes. To start with, aluminum is lightweight, making transportation and installation easy. This proves particularly beneficial in agricultural settings where mobility and flexibility are crucial. Moreover, aluminum boasts high resistance to corrosion, making it perfect for use in harsh environments like farms that often encounter moisture, chemicals, and fertilizers. By preventing rust, it ensures durability and longevity, reducing the need for frequent replacements. Additionally, aluminum profiles can be easily customized and fabricated to fulfill specific requirements. This flexibility enables the creation of structures such as greenhouse frames, support beams, shelving systems, and other components essential in agricultural operations. Furthermore, aluminum profiles are non-toxic and do not emit harmful substances into the surrounding environment. This characteristic ensures their safety for use in farming applications, where the well-being of animals and crops is of utmost importance. Lastly, aluminum is a sustainable material that can be recycled indefinitely, minimizing its environmental impact. This aligns with the increasing emphasis on sustainability in agriculture. To conclude, due to their lightweight nature, resistance to corrosion, adaptability, safety, and sustainability, aluminum profiles are indeed suitable for various agricultural and farming applications.

- Q: What are the advantages of using aluminum profiles in transportation vehicles?

- Using aluminum profiles in transportation vehicles offers several benefits. To begin with, aluminum is lighter than other metals like steel. This results in reduced fuel consumption and increased energy efficiency, making it perfect for vehicles that require frequent movement and long distances. Moreover, the lightweight nature of aluminum improves maneuverability and handling, enhancing overall vehicle performance. Secondly, aluminum profiles provide excellent corrosion resistance. This is especially important for transportation vehicles that face harsh weather conditions and corrosive elements like salt and moisture. Aluminum's corrosion resistance ensures the vehicle's longevity and durability, reducing maintenance and repair costs. Additionally, aluminum profiles are highly recyclable. The recycling process for aluminum requires less energy compared to producing primary aluminum. This not only reduces greenhouse gas emissions but also contributes to the sustainability of the transportation industry. Aluminum's recyclability aligns with the growing focus on eco-friendly practices. Furthermore, aluminum profiles offer great design flexibility. They can be easily extruded into various shapes and sizes, allowing manufacturers to create customized components and structures for transportation vehicles. This flexibility optimizes space and weight distribution, resulting in improved efficiency and functionality. Lastly, aluminum profiles are non-toxic and non-magnetic. This is advantageous in transportation vehicles as it eliminates the risk of interference with sensitive electronic systems and equipment. Aluminum's non-toxic nature also makes it a safe choice for transporting food and other sensitive materials. In conclusion, there are numerous advantages to using aluminum profiles in transportation vehicles. Its lightweight, corrosion resistance, recyclability, design flexibility, and non-toxic properties make it an ideal material for enhancing fuel efficiency, durability, sustainability, and overall performance in the transportation industry.

- Q: Are aluminum profiles suitable for electrical conductivity applications?

- Electrical conductivity applications are not suitable for aluminum profiles. Despite aluminum being a proficient conductor of electricity, the presence of an oxide layer on the surface of aluminum profiles typically obstructs electrical conductivity. Furthermore, aluminum profiles are susceptible to corrosion, ultimately affecting their conductivity. Consequently, materials with superior conductivity attributes like copper or silver are generally favored for electrical conductivity applications.

- Q: How do aluminum profiles perform in terms of sound insulation?

- Aluminum profiles typically offer poor sound insulation due to their lightweight and low density. They do not effectively block or absorb sound waves, making them less suitable for applications that require high levels of soundproofing.

- Q: Are aluminum profiles resistant to chemicals and acids?

- Yes, aluminum profiles are generally resistant to chemicals and acids due to their natural oxide layer that provides a protective barrier against corrosion. However, certain highly corrosive chemicals or acids may still cause damage over time.

- Q: This question asks whether aluminum profiles can be recycled and if so, the process involved in recycling them.

- <p>Yes, aluminum profiles can be recycled. The recycling process typically involves collection, sorting, and shredding the aluminum profiles. After shredding, the material is melted in a furnace, which separates impurities and leaves behind pure aluminum. This molten aluminum can then be cast into new profiles or other products. The recycling of aluminum is energy-efficient and environmentally friendly, as it requires only 5% of the energy needed to produce aluminum from raw materials. This makes aluminum recycling a sustainable practice that helps conserve resources and reduce waste.</p>

- Q: 30*40 how much aluminum meter?

- 3040 aluminum price, looking for Shanghai Bei pie. Aluminum specifications are complete, the corresponding parts are.

Send your message to us

Aluminium Extrusion Profiles For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords