Aluminium Profile Extrusion Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile Extrusion Windows and Doors Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Extrusion Windows and Doors:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

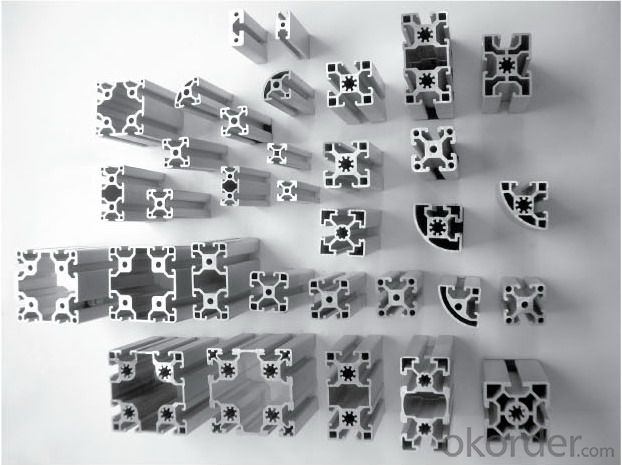

3.Aluminium Profile Extrusion Windows and Doors Images:

4.Aluminium Profile Extrusion Windows and Doors Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can aluminum sheets be used for modular construction?

- Absolutely, modular construction can utilize aluminum sheets. Aluminum proves to be an adaptable and lightweight substance that presents numerous advantages for modular construction undertakings. Its resilience, resistance to corrosion, and impressive strength-to-weight ratio render it appropriate for a wide range of structural applications. The malleability of aluminum sheets permits them to be effortlessly fabricated and molded into various forms and dimensions, enabling flexibility in both design and construction. Furthermore, aluminum's recyclability positions it as an environmentally conscious selection for sustainable construction practices. All things considered, aluminum sheets stand as a feasible choice for modular construction given their robustness, durability, and versatility.

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: Are aluminum sheets suitable for automotive applications?

- Aluminum sheets are indeed suitable for automotive applications. Aluminum, being a lightweight material, presents several advantages for automotive use. To begin with, aluminum boasts exceptional resistance against corrosion, making it an excellent choice for exterior parts that are exposed to harsh environments. Moreover, aluminum offers a remarkable strength-to-weight ratio, ensuring high durability while keeping the overall weight of the vehicle at a minimum. Consequently, this results in enhanced fuel efficiency and superior performance. Furthermore, aluminum sheets are highly malleable, enabling manufacturers to fashion intricate shapes and designs for a variety of automotive components. Additionally, aluminum is recyclable, making it a sustainable option for the environment. All in all, the utilization of aluminum sheets in automotive applications provides numerous benefits, including weight reduction, improved fuel efficiency, resistance to corrosion, and flexibility in design.

- Q: How are aluminum sheets different from aluminum plate?

- There are two forms of aluminum metal, namely aluminum sheets and aluminum plates, which primarily differ in terms of thickness. Aluminum sheets are usually thin and flat, with a thickness of less than 6mm. They are commonly utilized in situations where lightweight and flexibility are crucial, such as in the fabrication of aircraft, automobiles, and electronic devices. Conversely, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are frequently employed in applications that necessitate strength and durability, such as in the assembly of heavy machinery, structural supports, and marine equipment. Despite both sheets and plates being composed of aluminum, their distinctive thicknesses render them suitable for distinct purposes.

- Q: How does the aluminum plate manufacturer prevent the aluminum plate from scratching?

- Chaoyang aluminum manufacturers tell you that you can ask the manufacturer to cover the aluminum plate surface, to prevent aluminum plate scraping it!

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: a 1 kg block of aluminum and a 1 kg block of lead are immersed in water, Both sink, but which experienced the greater buoyant force? Why?

- Buoyant force = weight of water displaced The thing that affects the weight displaced is the volume of the metal blocks. Both Aluminum and Lead have the same mass (1kg) but Lead is more dense than Aluminum (11.34g/cm^3 vs 2.70g/cm^3). As such, the 1kg of Aluminum has a greater volume than Lead and hence experienced the greater buoyant force.

- Q: Can aluminum sheets be used for heat lamps?

- Yes, aluminum sheets can be used for heat lamps. Aluminum is a good conductor of heat, meaning it can effectively transfer and distribute heat. This property makes it suitable for use in heat lamps, which require efficient heat distribution to effectively warm objects or spaces. Additionally, aluminum is lightweight, durable, and has a high melting point, which makes it a practical choice for heat lamp applications.

- Q: answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

Send your message to us

Aluminium Profile Extrusion Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords