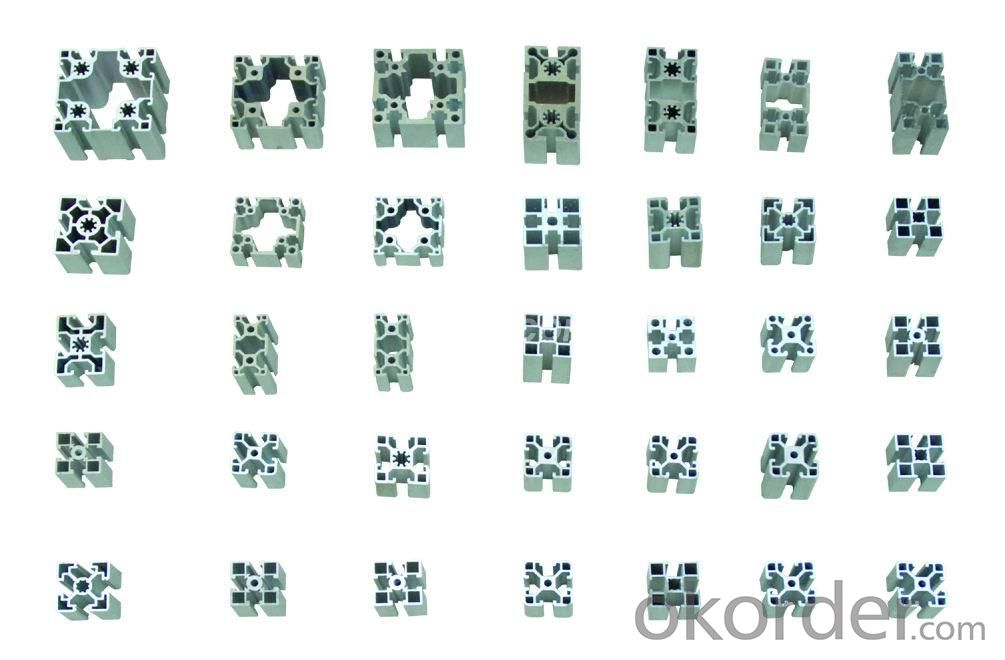

T Slot Aluminum Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight,ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector(as much as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengthsranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawnand extruded.

Advantage:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: What are the different bending options available for aluminum profiles?

- Depending on specific requirements and desired outcomes, there are various options available for bending aluminum profiles. Common methods include: 1. Roll Bending: Aluminum profiles can be passed between rollers to achieve the desired bend. This method is ideal for larger and thicker profiles, as it provides a gradual and consistent bend. 2. Press Bending: Hydraulic or mechanical presses can be used to shape the aluminum profile. This method is suitable for both small and large profiles and can achieve different bend angles. 3. Mandrel Bending: By inserting a rod or tube called a mandrel into the aluminum profile, its shape can be maintained during bending. This method ensures precise and uniform bends, making it suitable for complex shapes and tight radius bends. 4. Stretch Bending: Controlled stretching forces are applied to the aluminum profile, allowing it to flex and bend. This method is often used for profiles with large radii and gentle curves. 5. Rotary Draw Bending: Using a die and a rotating arm, the aluminum profile can be bent around a specific radius. This method is highly accurate and commonly used for precise and repeatable bends. 6. Heat Bending: Applying heat to the aluminum profile softens it before bending. Once the desired bend is achieved, the profile is cooled to retain its new shape. This method is suitable for profiles with complex shapes and sharp angles. Each bending option has advantages and limitations, and the selection depends on factors such as profile size, shape complexity, bend angle, and required precision. It is recommended to consult with a professional or bending specialist to determine the most appropriate method for specific aluminum profile applications.

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: This question asks about the effects of utilizing aluminum profiles in the construction industry on the environment.

- <p>The environmental impacts of using aluminum profiles in construction are multifaceted. On the positive side, aluminum is lightweight and strong, reducing the amount of material needed and potentially decreasing energy consumption in transportation. It is also recyclable, which can reduce waste and the need for raw material extraction. However, the production of aluminum requires significant energy, often from non-renewable sources, contributing to carbon emissions. Additionally, while recycling reduces environmental impact, it still consumes energy and can generate waste. The longevity and durability of aluminum can lead to less frequent replacement, reducing construction waste, but improper disposal can lead to pollution. Overall, the environmental impact depends on the balance between these factors and the specific practices of aluminum production and use in construction.</p>

- Q: Can aluminum profiles be used in the production of signage?

- Yes, aluminum profiles can be used in the production of signage. Aluminum profiles are popular in the signage industry due to their durability, versatility, and aesthetic appeal. They can be easily shaped and cut into various sizes and designs, making them suitable for different types of signage such as indoor and outdoor signs, lightboxes, channel letters, and more. Aluminum profiles are also lightweight, corrosion-resistant, and weatherproof, allowing them to withstand harsh environmental conditions and ensure long-lasting signage. Additionally, aluminum profiles can be easily painted, powder-coated, or anodized in different colors, providing endless design possibilities for signage projects. Overall, using aluminum profiles in signage production offers numerous advantages in terms of durability, customization, and visual appeal.

- Q: Can aluminum profiles be used for electrical busbars?

- Indeed, aluminum profiles are capable of serving as electrical busbars. The utilization of aluminum in busbars is widespread as a consequence of its exceptional electrical conductivity, affordability, and lightweight properties. Aluminum profiles present a dependable and effective means for electrical distribution across a range of scenarios, encompassing power distribution systems, switchboards, and control panels. They boast commendable thermal conductivity, aiding in the dissipation of heat produced during periods of intense current flow. Nevertheless, when opting for aluminum profiles for busbar applications, it is crucial to take into account factors such as current carrying capacity, mechanical strength, and electrical insulation requirements.

- Q: Aluminum profile spraying process

- Pretreatment -- drying, removing moisture -- spraying -- Inspection -- baking -- Inspection -- finished.1, construction requirements, general powder spraying construction requirements:(1) in order to give full play to and extend the service life of the coating, the surface of the coating is strictly treated by surface pretreatment first(2) when spraying, the coating must be completely ground to increase the spraying efficiency of the powder coating(3) to be coated with larger surface defects, it should be coated with conductive putty to ensure the smooth and smooth coating(4) after the spraying, the objects and articles should be heated, cured and solidified. The technical indexes of the powder products should be adopted, but the curing temperature and time should be guaranteed so as to avoid the quality failures caused by solidification(5) check immediately after spraying, if found defects should be timely treatment, if after curing defects are found, the only local small range without affecting, the coated surface decoration, can use the same color powder and acetone diluted to repair, if the scope is large and affects the surface quality, use sandpaper after again. Or use the paint remover to remove the coating, re Suo powder.(6) the recovered powder must be screened and removed, and then mixed with the new powder at a certain proportion(7) the powder supply barrel, the powder spraying room and the recycling system should avoid contamination by other colors. Therefore, each color change must be cleaned

- Q: This question asks if aluminum profiles can be recycled with ease and at a low cost.

- <p>Yes, aluminum profiles can be recycled easily and at a low cost. Aluminum has one of the highest recycling rates among metals due to its non-toxic nature and the fact that it does not lose quality when recycled. The recycling process is energy-efficient, requiring only 5% of the energy needed to produce new aluminum. Additionally, the cost of recycling aluminum is significantly lower than the cost of mining and processing new aluminum, making it an economically viable and environmentally friendly option.</p>

- Q: This question asks about the methods to ensure that aluminum profiles used in construction meet safety standards.

- <p>To ensure that aluminum profiles used in building construction meet safety standards, you should follow these steps: 1) Source from reputable suppliers who adhere to industry standards. 2) Check for certifications such as ISO 9001 for quality management. 3) Verify the aluminum's grade and alloy type to ensure it's suitable for construction use. 4) Conduct regular inspections and tests, including tensile strength and load-bearing capacity tests. 5) Adhere to local building codes and regulations. 6) Use profiles with appropriate thickness and dimensions for the intended application. 7) Consult with engineers or architects to ensure proper design and installation. 8) Keep records of all tests and inspections for future reference and compliance checks.</p>

- Q: Can aluminum profiles be used for stadium seating?

- Yes, aluminum profiles can be used for stadium seating. Aluminum is a lightweight and durable material that is commonly used in various construction applications, including stadium seating. It offers the advantage of being corrosion-resistant, easy to maintain, and can be customized to meet specific design requirements. Additionally, aluminum profiles provide structural stability and can withstand heavy loads, making them suitable for stadium seating systems.

- Q: Are aluminum profiles suitable for signage and advertising displays?

- Yes, aluminum profiles are suitable for signage and advertising displays. They are lightweight, durable, and corrosion-resistant, making them ideal for indoor and outdoor applications. Aluminum profiles can be easily customized and fabricated to create various shapes and sizes, allowing for versatile and eye-catching signage and advertising displays. Additionally, they offer a sleek and modern appearance, enhancing the overall aesthetics of the display.

Send your message to us

T Slot Aluminum Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords