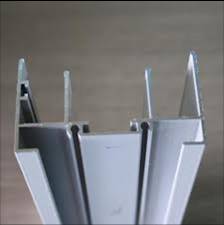

Large Aluminum Extrusion Profiles for Window Frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Item: | aluminium window and door profile |

Material: | 100% alloy :6063-T5,6061-T6,6463-T5,7075-T6,6082,5052,2024,7005,6013,7020 etc. |

Size: | 3m-6m or customized size |

Application | Furniture, windows & doors, decorations ,industry, construction etc. |

Colors: | Anodized, wood grain,powder coating, anodised polished and brushed, electrophoresis, flurocarbon powder coated etc. |

MOQ: | 500KG for each profile |

OEM service | based on customer designed drawings or samples |

Certification | ISO:9001, SONCAP , BV Certificate or customers’ Certificate Available |

Packing Detail | (1)Inside : packed with plastic protective film to protect each profile |

(2)Outside:packed with waterproof kraft paper | |

Delivery time: | (1)Die Developing and Sample test : 12-18days . |

(2)Production duration:25-30days after sample is confirmed by Buyer. | |

Payment term: | T/T, 30% down payment while balance shall be paid off before delivery. |

Settlement : | Final payment shall be based on final actual physical weighing. |

Capacity: | 2400-3000 Metric tonnes per month. |

Guarantee | Surface color is able to sustain for 10~20 years for indoor using. |

Port: | FOB Shenzhen, Guangzhou, Foshan |

Strong resistance corrosion property, effectively prevent acid, alkali, and salt etc.

Smooth and subtle, vivid, bright, and magnificent appearance

Alloy: 6063

Finish: anodizing, electrophoretic coating, powder coating, wood effect etc according to customers’ need

Standard package: suitable for long ocean transporting

OEM&ODM is welcome

Last for life time

- Q: Are aluminum profiles suitable for bathroom fittings and accessories?

- Yes, aluminum profiles are suitable for bathroom fittings and accessories. Aluminum is a corrosion-resistant material that can withstand moisture and humidity in a bathroom environment. Additionally, aluminum profiles offer versatility in design, durability, and are lightweight, making them an ideal choice for bathroom fittings and accessories.

- Q: Can aluminum profiles be used in the construction of stadium seating systems?

- Indeed, stadium seating systems can utilize aluminum profiles for their construction. Aluminum, being both lightweight and long-lasting, is frequently employed in a multitude of construction applications, including stadium seating systems. It presents numerous benefits, such as resistance to corrosion, a high strength-to-weight ratio, and ease of fabrication. By customizing and assembling aluminum profiles, seating structures that are sturdy, stable, and aesthetically pleasing can be easily created. Moreover, due to its lightweight nature, aluminum allows for simpler installation and transportation, making it a financially prudent choice for stadium seating systems. All in all, when considering their durability, versatility, and strength, aluminum profiles emerge as an appropriate selection for constructing stadium seating systems.

- Q: Shanghai industrial aluminum profile manufacturers which is better?

- Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: What are the different colors available for aluminum profiles?

- The different colors available for aluminum profiles can vary depending on the manufacturer or supplier. However, some common color options include natural silver, black, white, bronze, gold, and various shades of gray. Additionally, there are also custom color options available where aluminum profiles can be powder coated or anodized in a wide range of colors to suit specific design requirements.

- Q: Can aluminum profiles be used in the production of industrial robots?

- Yes, aluminum profiles can be used in the production of industrial robots. Aluminum is a lightweight and durable material that offers several advantages for constructing robotic systems. It has a high strength-to-weight ratio, making it suitable for building rigid and reliable robot structures. Aluminum profiles can be easily machined, allowing for precise and intricate designs to be created for various robot components such as frames, arms, and joints. Additionally, aluminum is corrosion-resistant, which is beneficial in industrial settings where robots may be exposed to harsh environments or chemicals. Overall, aluminum profiles provide a cost-effective and versatile solution for manufacturing industrial robots.

- Q: What are the advantages of using aluminum profiles in the aviation industry?

- There are several advantages of using aluminum profiles in the aviation industry. Firstly, aluminum is lightweight, which helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and lower operating costs. Secondly, aluminum profiles offer excellent strength-to-weight ratio, providing structural integrity and durability to withstand the demanding conditions of aviation. Thirdly, aluminum is corrosion-resistant, making it ideal for withstanding the effects of moisture and other environmental elements. Additionally, aluminum profiles are easy to fabricate, allowing for efficient manufacturing processes and quicker turnaround times.

- Q: the middle of the following is a groove structure, as if you can not bolt hole, then how to install the rail on it? What's the use of flat sealing strips and slip bars embedded inside? Is it necessary to mount the guide rail on the aluminum profile, you can choose more than 6060 of the profiles, the middle is flat structure, and then drill holes in the bolt connection rail Thanks

- Use the T nut (in the T groove) to fit the rail, the flat sealing strip, and the slip bar embedded in it for dust, waterproof, oil proof and so on.Guide (TTW): metal or other materials made of grooves or ridges, can withstand, fixed, and guide the movement of devices or equipment, and reduce its friction of a device.

- Q: This question asks for a list of various fastening methods or components used to attach aluminum profiles in roofing systems.

- <p>In roofing systems, various types of fasteners are used to secure aluminum profiles, ensuring stability and longevity. Some common fasteners include: 1. Self-tapping screws, which thread directly into the aluminum without pre-drilling. 2. Rivets, which join two pieces of aluminum by compressing them together. 3. Nuts and bolts, used in conjunction with pre-drilled holes for a secure fit. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, used for bonding profiles in situations where mechanical fasteners are not suitable. 6. Clips and brackets, which can be used to attach profiles to other structural elements. Each type of fastener has its specific application and is chosen based on the design requirements and environmental conditions of the roofing system.</p>

- Q: Can aluminum profiles be used in load-bearing structures?

- Yes, aluminum profiles can be used in load-bearing structures. Aluminum is a lightweight and durable material that offers high strength-to-weight ratio, making it suitable for load-bearing applications. It is commonly used in construction, aerospace, and automotive industries where its strength and structural integrity are essential.

- Q: What are the specific requirements or considerations when using aluminum profiles in the construction or design of swimming pools and spas?

- <p>Yes, there are special requirements for using aluminum profiles in swimming pools and spas. These include corrosion resistance to withstand chlorinated water, which is common in pools and spas. Profiles must be made of marine-grade aluminum to prevent rust and ensure longevity. They should also be able to withstand high humidity and temperature fluctuations. Additionally, profiles need to be non-slip and easy to clean to maintain safety and hygiene. The design should also consider structural integrity to support the weight of the pool or spa structure and any associated equipment.</p>

Send your message to us

Large Aluminum Extrusion Profiles for Window Frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords