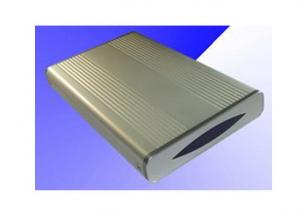

High Quality Extruded Aluminum Enclosure Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Color | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

- Q: What are the different shapes available for aluminum profiles?

- There are various shapes available for aluminum profiles, each designed to suit different applications and requirements. Some commonly used shapes include: 1. T-Slot profiles: These profiles have a T-shaped cross-section, with slots on one or more sides. They are widely used in construction, robotics, and industrial applications, as they allow for easy assembly and integration of other components. 2. Square profiles: These profiles have a square-shaped cross-section and are often used for structural applications. They provide excellent strength and rigidity, making them suitable for building frames, machine bases, and support structures. 3. Rectangular profiles: Similar to square profiles, rectangular profiles have a rectangular-shaped cross-section. They offer versatility and can be used in a wide range of applications, including enclosures, partitions, and conveyor systems. 4. Round profiles: These profiles have a circular cross-section and are commonly used in applications that require a smooth and aesthetically pleasing finish. They are often used for architectural purposes, such as handrails, furniture, and decorative elements. 5. L-Shaped profiles: L-shaped profiles have a 90-degree angle and are often used for corner joints, edges, and brackets. They provide structural support and stability and are commonly used in construction and manufacturing industries. 6. U-Shaped profiles: U-shaped profiles have a U-shaped cross-section, resembling an open channel. They are frequently used in applications that require a protective housing or a channel to guide cables, wires, or other components. 7. Custom profiles: Apart from the standard shapes mentioned above, aluminum profiles can also be custom-designed and manufactured to meet specific project requirements. This allows for greater flexibility and ensures the aluminum profiles perfectly fit the intended application. Overall, the availability of different shapes for aluminum profiles enables engineers, designers, and manufacturers to select the most appropriate shape for their specific needs, ensuring optimal performance, functionality, and aesthetics.

- Q: What are the different accessories available for aluminum profiles?

- There are a wide range of accessories available for aluminum profiles that can enhance their functionality and versatility. Some of the common accessories include: 1. T-nuts: T-nuts are used to create threaded connections within aluminum profiles, allowing for easy attachment of various components such as brackets, panels, and fasteners. 2. Corner connectors: These connectors are used to join aluminum profiles at right angles, enabling the creation of sturdy and rigid structures. They come in various designs, such as external or internal corner connectors. 3. End caps: End caps are used to seal the open ends of aluminum profiles, providing a clean and finished look while also protecting against dust, debris, and potential injuries. 4. Brackets and fasteners: Brackets and fasteners are essential accessories for securing and supporting components within aluminum profiles. They come in various shapes and sizes to accommodate different applications. 5. Panel mounts: Panel mounts provide a secure and convenient way to attach panels, boards, or other flat surfaces to aluminum profiles. They can be easily adjusted or removed as needed. 6. Hinges and handles: These accessories are commonly used in applications where doors, lids, or covers need to be attached to aluminum profiles. Hinges allow for smooth opening and closing, while handles provide a comfortable grip. 7. Cable management solutions: Cable management accessories such as cable clips, cable ducts, and cable ties are available to keep wires and cables organized within aluminum profiles, ensuring a neat and professional appearance. 8. Leveling feet and casters: Leveling feet and casters are useful accessories for aluminum profile-based structures that need to be mobile or require stability on uneven surfaces. Leveling feet help adjust the height and ensure stability, while casters provide mobility. 9. LED lighting solutions: Aluminum profiles are often used for LED lighting applications, and various accessories are available to integrate lighting strips, diffusers, and connectors for a seamless and professional lighting solution. 10. Sensors and switches: Accessories like sensor mounts and switch brackets are designed to integrate sensors or switches into aluminum profiles, allowing for easy installation and integration into automation or control systems. These are just a few examples of the many accessories available for aluminum profiles. The wide range of options allows for customization and adaptation to specific needs and applications, making aluminum profiles a versatile and reliable choice for various industries and projects.

- Q: Is it possible to recycle aluminum profiles and repurpose them for different uses?

- <p>Yes, aluminum profiles can be recycled and reused in other applications. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for a variety of new applications, such as construction, automotive, and consumer goods. The recycling of aluminum profiles not only conserves resources but also reduces waste and environmental impact.</p>

- Q: Are aluminum profiles suitable for medical equipment?

- Indeed, medical equipment finds aluminum profiles to be highly suitable. Aluminum, being a material that is both lightweight and strong, exhibits exceptional resistance to corrosion, thereby rendering it exceptionally appropriate for deployment in medical equipment. The ease with which aluminum can be transformed into diverse profiles and shapes further enhances its ability to meet specific demands. Moreover, aluminum possesses non-toxic, non-magnetic characteristics, and can be readily sterilized, thus rendering it completely safe for employment in medical settings. Furthermore, its capacity to withstand wear and tear, along with its durability, further amplifies its suitability for medical equipment, thereby ensuring extended and dependable functionality.

- Q: This question asks for a list of various interior wall cladding systems that incorporate aluminum profiles.

- <p>Aluminum profiles are versatile and commonly used in interior wall cladding systems due to their durability and aesthetic appeal. Some of the different types include: 1. Aluminum Composite Panels (ACP), which combine two aluminum sheets with a non-aluminum core. 2. Aluminum Insulated Panels, offering thermal insulation properties. 3. Aluminum Curtain Wall Systems, providing a weather-resistant exterior wall. 4. Aluminum Lining Systems, used for decorative purposes and easy maintenance. 5. Aluminum Ceiling Systems, which can also serve as wall cladding in some designs. 6. Aluminum Drywall Systems, which are lightweight and easy to install. Each system has its specific applications and advantages, making aluminum profiles a popular choice in modern architecture and interior design.</p>

- Q: How are the tonnage grades of aluminum extrusion machines classified?

- Aluminum material is soft, so it is easy to produce the top injury, pressure injury, scratch and deformation in the stamping production. Besides the requirements on the die, the following points should be done in the stamping process:1, to make aluminum stamping, reducing non-performing rate, the first to do 5S, especially clean, including mold, punch table, pipeline and packaging materials must be no sharp debris, no dirt regularly clear rectification, the upper and lower mold must be clean without debris.2, found that product burr larger, must promptly send mold maintenance, and follow the results.3, aluminum parts easier to heat, and the backlog of hard together, so in the blanking, when the material needs to be coated with a little pressure on the oil (to heat dissipation, but also smooth to clear the material), and then stamping.4, punching more products need to do blow cleaning the mold surface, do product mould, keep clean, reduce top injury, injury must be found on top of the mold top point to find out and solve the injury problems to continue production.5, push the flat mold block will produce aluminum chip, so push block production every day, must be washed under the push block aluminum scrap.Our company with advanced production equipment and technology, relying on a strong technical team, and has established a perfect quality management system, ensure the reliable quality of products, products with first-class quality, reasonable price, sold in the city and region, sales performance is good, whether we are in a peer or in the guest account, have a high reputation.

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

- Q: This question asks for the various types of paint that can be used to protect aluminum profiles from weathering.

- <p>Aluminum profiles can be protected from weathering through the application of different types of paints. These include: 1) Powder Coating, which provides a durable and weather-resistant finish. 2) Anodizing, a process that increases the thickness of the natural oxide layer on aluminum, enhancing its resistance to corrosion. 3) Liquid Coatings, such as acrylic or polyester-based paints, which offer a range of colors and finishes. 4) Fluorocarbon Paints, known for their excellent resistance to UV rays and weathering. Each type has its own advantages and is chosen based on the specific requirements for durability, appearance, and environmental conditions.</p>

- Q: Are aluminum profiles suitable for use in industrial settings like shelving and storage systems?

- <p>Yes, aluminum profiles are indeed suitable for industrial applications such as shelving and storage systems. They offer several advantages including high strength-to-weight ratio, corrosion resistance, and ease of assembly. Aluminum profiles are lightweight, which makes them ideal for constructing sturdy yet lightweight shelving and storage solutions. Their resistance to corrosion means they can withstand harsh industrial environments without rusting. Additionally, the modular nature of aluminum profiles allows for customizable designs that can be easily adjusted or reconfigured to meet changing storage needs.</p>

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

High Quality Extruded Aluminum Enclosure Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords