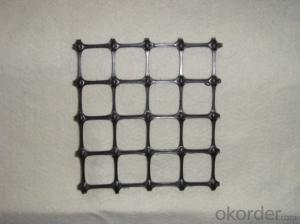

Hdpe Geogrid

Hdpe Geogrid Related Searches

Hdpe Uniaxial Geogrid Hdpe Geomembrane Machine Geomembrane Hdpe Hdpe Geomembrana Geomembrana Hdpe Geomembrane In Hdpe Geomembran Hdpe Honeycomb Geogrid Heet Geogrid Gse Hdpe Geomembrane Wholesale Geomembrane Hdpe Jual Geomembrane Hdpe Hdpe Geomembrane Installation Wholesale Hdpe Geomembrane Hdpe Geomembrane Welding Geomembrana De Hdpe Hdpe Textured Geomembrane Hdpe Geomembrane Specifications Hdpe Smooth Geomembrane Hdpe Geomembrane Sheet Hdpe Geomembrane Hs Code Wholesale Hdpe Geomembrana Geogrid Machine Dupont Geogrid Hdpe Geomembrane China Gravel Geogrid Ace Geogrid Geomembrana In Hdpe Huesker Geogrid Hdpe MembraneHdpe Geogrid Supplier & Manufacturer from China

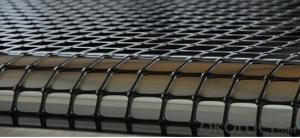

HDPE Geogrid is a high-performance geosynthetic material made from high-density polyethylene (HDPE), which is widely used in civil engineering and construction projects for soil reinforcement and stabilization. This product is designed to enhance the load-bearing capacity of soil and prevent subgrade deformation, making it an essential component in various applications.HDPE Geogrid finds its application in a variety of scenarios, including road construction, railway embankments, slope protection, and landfill liners. Its usage is particularly beneficial in situations where soil conditions are poor or where increased stability and load distribution are required. By incorporating HDPE Geogrid into these projects, engineers can achieve improved structural integrity, reduced maintenance costs, and extended service life for the infrastructure.

Okorder.com is a leading wholesale supplier of HDPE Geogrid, offering a vast inventory of this essential geosynthetic material. With a commitment to quality and customer satisfaction, Okorder.com ensures that their products meet the highest industry standards and are available at competitive prices. This makes them an ideal choice for contractors and engineers seeking a reliable source for HDPE Geogrid to incorporate into their projects.

Hot Products