Fiberglass Geogrid/Polyester Geogrid/PP Geogrid/HDPE Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

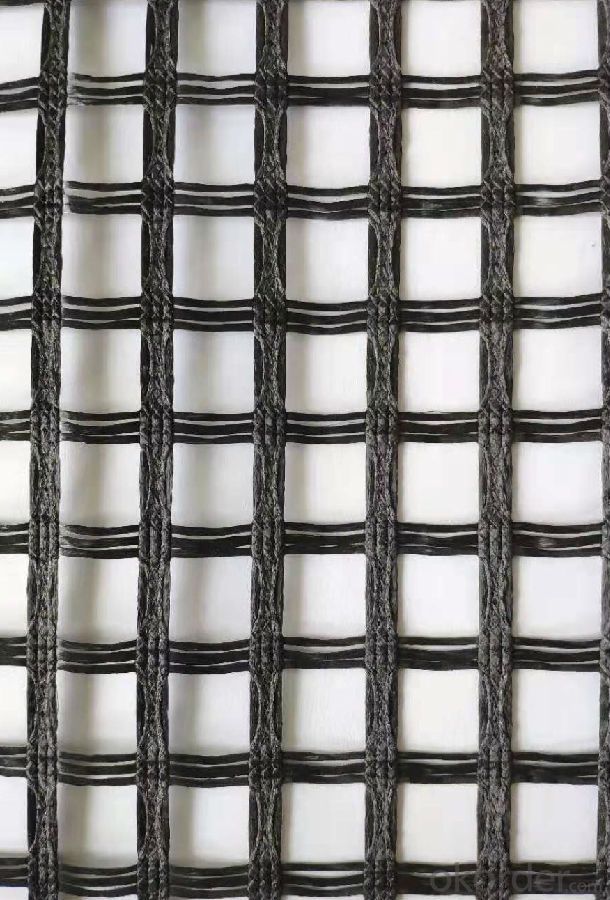

Fiberglass Geogrid:

1.Description of Fiberglass Geogrid:

CMAX fiberglass geogrid is made from glass fiber by weaving technology and coating treatment.

2.Specification of Fiberglass Geogrid

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

3.Technical Data Sheet

Item | CMAX30-30 | CMAX50-50 | CMAX80-80 | CMAX100-100 | CMAX120-120 | CMAX150-150 | |

Mesh Size(mm) | 25.4 x 25.4 or 12.5 x 12.5 or 50.8x 50.8 | ||||||

Breaking strength | Warp direction | 30 | 50 | 80 | 100 | 120 | 150 |

Across warp | 30 | 50 | 80 | 100 | 120 | 150 | |

Elongation at break % | Warp direction | 4 | |||||

Across warp | 4 | ||||||

Thermal tolerance (℃) | -100 ~280 | ||||||

Width(m) | 6 | ||||||

4.Property of Fiberglass Geogrid:

1). High strength, low elongation;

2). Heat-resistant, high modulus.

3). Light weight, good flexibility.

4). Anti-erosion, long life time.

5.Application of Fiberglass Geogrid

1). Roadbed reinforcement, prevent road surface crack.

2). Road reconstruction

3). Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

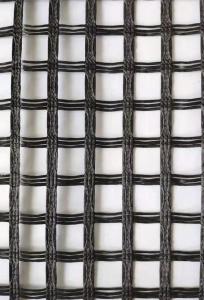

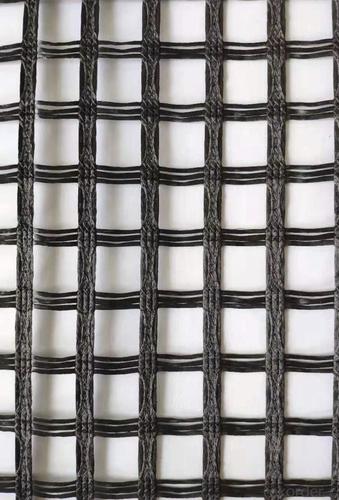

Polyester Geogrid

1.Description of Polyester Geogrid

CMAX polyester geogrid is made from polyester fiber by weaving technology after gummed processing.

2.Specification of Polyester Geogrid

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN; 150-150KN; 200-200KN;

Road Size: 3.95x100m; as customer required;

3. Technical Data Sheet of Polyester Geogrid

Item | Unit | Index | ||||||||||||||||||||||

Tensile Strength | Warp | KN/m | 55 | 80 | 100 | 120 | 150 | 200 | 300 | 400 | 600 | 800 | 1200 | |||||||||||

Weft | KN/m | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 50 | 50 | 100 | 200 | ||||||||||||

Elongation | % | 13 or 10 | ||||||||||||||||||||||

Grid size | Mm | 25.4x25.4 or 50.8x50.8 or 76.2x76.2 | ||||||||||||||||||||||

Width | M | 2 or 4 or 5.2 or 6 | ||||||||||||||||||||||

Item | Unit | Index | ||||||||||||||||||||||

Tensile Strength | Warp | KN/m | ||||||||||||||||||||||

Weft | KN/m | |||||||||||||||||||||||

Elongation | % | 13 or 10 | ||||||||||||||||||||||

Grid size | Mm | 25.4x25.4 or 50.8x50.8 or 76.2x76.2 | ||||||||||||||||||||||

Width | m | 2 or 4 or 5.2 or 6 | ||||||||||||||||||||||

4. Property of Polyester Geogrid

1). High tensile strength

2). Low elongation

3).Anti-erosion, anti-aging

4).Good affinity with base material

5). Light weight, water drainage

5.Application of Polyester Geogrid

1). Roadbed reinforcement in highway, railway and municipal road.

2).Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

3).Roadbed slope reinforcement, retaining wall renforcement.

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: How much is a glass fiber mesh

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, high tensile strength, elasticity, tensile strength and elongation between alkali resistant glass fiber mesh elastic limit, so the glass fiber mesh cloth price range is large, with "Jining wellav" WL-0812 series products the price, floating in the price range of $0.32--5

- Q: Are geogrids suitable for use in agricultural applications?

- Yes, geogrids are suitable for use in agricultural applications. They can be used to strengthen soil and improve stability, reducing erosion and preventing soil compaction. Additionally, geogrids can enhance the performance of agricultural structures such as retaining walls, embankments, and roadways, making them a valuable tool in agricultural engineering.

- Q: Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- So I can give you a good price

- Q: Can geogrids be used in temporary construction platforms?

- Yes, geogrids can be used in temporary construction platforms. Geogrids are commonly used in construction projects to reinforce soil and provide stability. They can be used as a cost-effective solution for temporary construction platforms by improving load-bearing capacity and preventing soil erosion.

- Q: How do geogrids enhance soil reinforcement?

- Geogrids enhance soil reinforcement by providing additional tensile strength and stability to the soil. They are placed within the soil layers and act as a reinforcement material, distributing the forces and reducing the potential for soil movement. This helps to increase the overall strength and performance of the soil, making it more resistant to erosion, deformation, and other types of failures.

- Q: Can geogrids be used in reinforcement of bridge abutments and wing walls?

- Yes, geogrids can be used in the reinforcement of bridge abutments and wing walls. Geogrids are commonly used in civil engineering projects to provide stability and increase the load-bearing capacity of soil. By placing geogrids in the backfill soil behind bridge abutments and wing walls, they can help distribute the loads and prevent soil erosion. This reinforcement technique improves the overall structural integrity of the bridge and enhances its long-term performance.

- Q: How do geogrids help in reducing the risk of foundation settlement?

- Geogrids help in reducing the risk of foundation settlement by providing additional support and stability to the soil beneath the foundation. They act as a reinforcement material that enhances the load-bearing capacity of the soil, preventing it from shifting or settling. This helps distribute the weight of the structure more evenly, reducing the potential for uneven settlement and potential damage to the foundation.

- Q: Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used in ground stabilization for water treatment plants. Geogrids are commonly used in civil engineering projects to improve the stability and load-bearing capacity of soil. In the case of water treatment plants, geogrids can help prevent soil erosion, reinforce embankments, and provide stability to the ground, ensuring the safe and long-lasting operation of the facility.

- Q: Glass fiber mesh cloth is mainly used in what place

- Wall materials (such as glass fiber wall cloth, GRC wall panels, EPS internal and external wall insulation board, gypsum board, etc.)

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials, typically made from polymer materials such as polyethylene or polypropylene, that are used in civil engineering and construction projects. These materials possess several important properties and characteristics. Firstly, geogrids have high tensile strength, which allows them to effectively distribute loads and provide structural reinforcement to the soil. They also have excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various environmental conditions. Geogrids are lightweight, flexible, and easy to handle, making installation and transportation more convenient. Additionally, these materials exhibit low elongation and creep characteristics, ensuring long-term stability and performance. Overall, geogrids offer superior soil stabilization, erosion control, and reinforcement properties, making them valuable in a wide range of geotechnical and construction projects.

Send your message to us

Fiberglass Geogrid/Polyester Geogrid/PP Geogrid/HDPE Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords