Uniaxial and Biaxial Geogrids - High Tensile HDPE Geogrid for Retaining Wall/Road Construction (CE & Factory)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Tensile HDPE Uniaxial Geogrid for Retaining Wall/Road Construction(CE&factory)

1.Introduction of High Tensile HDPE Uniaxial Geogrid for Retaining Wall/Road Construction(CE&factory)

CMAX Uniaxial Geogrid is manufactured by a process of extruding, punching, heating and longitudinal stretching.

It is made of high density polythylene and they are chemically inert, unaffected by the U.V. rays and fully resistant to aging in the soil environment

2.Performance of High Tensile HDPE Uniaxial Geogrid for Retaining Wall/Road Construction(CE&factory)

High strength

Good flexibility

Anti-aging

Resisting acid and alkaline

3. Specification of High Tensile HDPE Uniaxial Geogrid for Retaining Wall/Road Construction(CE&factory)

Item | Unit | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG160 |

Width | m | 1.1~2.5 | 1.1~2.5 | 1.1~2.5 | 1.1~2.5 | 1.1~2.5 |

Tensile strength | kN/m | 35 | 50 | 80 | 110 | 160 |

Elongation | % | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 |

Tensile strength at 2% strain | kN/m | 7.5 | 12 | 21 | 30 | 47 |

Tensile strength at 5% strain | kN/m | 21.5 | 23 | 40 | 58.75 | 93 |

4. Application of High Tensile HDPE Uniaxial Geogrid for Retaining Wall/Road Construction(CE&factory)

Make reinforcement for various kinds of soft soil foundation enhance and improve bearing ability of the roadbed,

make reinforcement for retaining wall, steep slope, dam and bridge abutment under stress status for long term thus to improve quality

and prolong service life of the project.

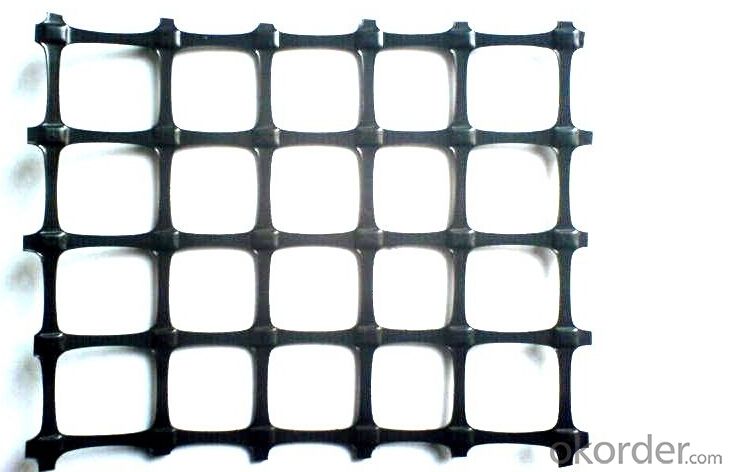

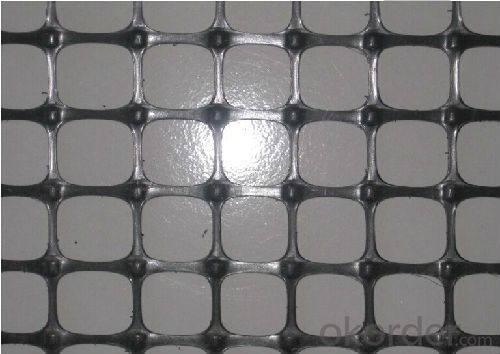

5. Photos of High Tensile HDPE Uniaxial Geogrid for Retaining Wall/Road Construction(CE&factory)

- Q: What is the role of Geogrid

- 3, geogrid for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.

- Q: Can geogrids be mechanically connected to other geosynthetics?

- Yes, geogrids can be mechanically connected to other geosynthetics.

- Q: What is the typical geogrid roll thickness for specific applications?

- The typical geogrid roll thickness for specific applications can vary depending on the specific project requirements and site conditions. However, geogrid rolls typically range from 2 to 10 millimeters in thickness for common applications such as soil stabilization, retaining walls, and road construction.

- Q: How do geogrids improve the performance of geocell-reinforced retaining walls?

- Geogrids enhance the performance of geocell-reinforced retaining walls by providing additional tensile strength and stability. They act as a reinforcement layer within the geocell structure, preventing soil movement and enhancing load distribution. This combination increases the overall strength of the retaining wall, allowing it to withstand higher loads and maintain structural integrity over time.

- Q: What is the meaning of the highway geogrid gsl50/hdpe

- Biaxial tensile plastic geogrid material is PP polyethylene, and I hope to help you, I am also a manufacturer of geogrid, information contact, if in doubt, please contact, hope to communicate with you, learning.

- Q: Are geogrids suitable for reinforcing slope stabilization mats?

- Yes, geogrids are suitable for reinforcing slope stabilization mats. Geogrids provide additional strength and stability to the mats, helping to prevent erosion and soil movement on slopes. They enhance the load-bearing capacity of the mats and improve their overall performance in stabilizing slopes.

- Q: Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids are commonly used in slope stabilization and reinforcement projects due to their high tensile strength and ability to distribute loads. They can effectively prevent soil erosion and provide stability to slopes during excavation, making them a reliable choice for such applications.

- Q: How do geogrids help in reducing construction equipment requirements?

- Geogrids help in reducing construction equipment requirements by providing soil stabilization and reinforcement. They act as a support structure, distributing loads and reducing the need for heavy machinery. This allows for cost-effective and efficient construction, minimizing the requirement for extensive equipment usage.

- Q: Are geogrids suitable for use in high-temperature environments?

- Yes, geogrids are suitable for use in high-temperature environments. Geogrids are constructed using materials that have high resistance to temperature, ensuring their durability and effectiveness even in extreme heat conditions. They can withstand elevated temperatures without losing their structural integrity, making them a reliable choice for various applications in high-temperature environments.

- Q: How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support and stability. They enhance the tensile strength of the geotextile tubes, preventing deformation and maintaining their shape under pressure. Geogrids also increase the overall load-bearing capacity of the geotextile tubes, making them more effective in erosion control, shoreline protection, and soil stabilization applications.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Uniaxial and Biaxial Geogrids - High Tensile HDPE Geogrid for Retaining Wall/Road Construction (CE & Factory)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords