Hdpe Membrane

Hdpe Membrane Related Searches

Geomembrane Hdpe Hdpe Geomembrana Geomembrana Hdpe Hdpe Geomembrane Machine Geomembran Hdpe Geomembrane In Hdpe Hdpe Textured Geomembrane Geomembrana De Hdpe Hdpe Smooth Geomembrane Gse Hdpe Geomembrane Wholesale Geomembrane Hdpe Geomembrana In Hdpe Hdpe Geomembrane Welding Wholesale Hdpe Geomembrane Hdpe Geomembrane Installation Hdpe Geomembrane Specifications Hdpe Geomembrane Factories Hdpe Geomembrane Sheet Reinforced Hdpe Geomembrane Hdpe Geomembrane China Kolam Geomembrane Hdpe Wholesale Hdpe Geomembrana Jual Geomembrane Hdpe Hdpe Geomembrane Price Hdpe Geomembrane Manufacturers Hdpe Geomembrane Hs Code Geomembrana Hdpe 2mm Hdpe Geomembrane Cost Hdpe Geomembrane Self Adhesive Solmax Geomembrane HdpeHdpe Membrane Supplier & Manufacturer from China

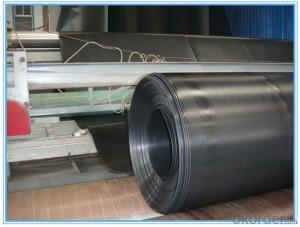

HDPE Membrane, also known as High-Density Polyethylene Membrane, is a type of plastic sheeting that is widely used for various applications due to its durability, flexibility, and resistance to chemicals and UV radiation. This product is manufactured with high-quality polyethylene resin, ensuring excellent performance and longevity in a range of environments.The HDPE Membrane is commonly utilized in the construction industry, particularly in waterproofing and geotechnical applications. It is often used for lining water reservoirs, ponds, and landfills, as well as for providing a barrier in road and railway construction projects. Additionally, it is employed in agriculture for pond lining and in the mining industry for tailings management. Its versatility makes it a popular choice for a variety of usage scenarios, offering a reliable solution to protect against water infiltration and contamination.

Okorder.com is a reputable wholesale supplier of HDPE Membrane, boasting a vast inventory that caters to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the HDPE Membranes they provide meet the highest standards of performance and durability. By offering a broad range of products and sizes, Okorder.com has established itself as a go-to source for businesses and contractors seeking reliable and cost-effective solutions for their projects.

Hot Products