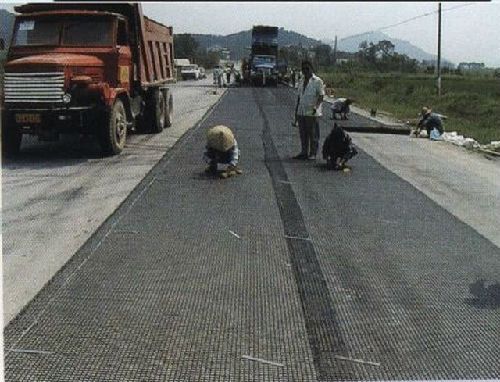

HDPE Biaxial Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.HDPE geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.

2.This product is made by HDPE. The products after surface covering own the favorable property of alkali resistance and aging resistance.

3.This product is also used to strengthen the soft land, such as railway, airport,irrigation work, and dyke, etc, and the roadbed.

HDPE Uniaxial geogrid Product Poperties

Specification | 50 | 60 | 80 | 90 | 100 | 110 | 120 | 150 | 160 | 190 | 220 |

Width( m) | 1 or 1.1 or 2.5 or 3 | ||||||||||

Tensile strength≥(kN/m) | 50 | 60 | 80 | 90 | 100 | 110 | 120 | 150 | 160 | 190 | 220 |

Elongation ≤(%) | 11.5 | ||||||||||

Tensile strength at 2% strain≥(kN/m) | 12 | 14 | 21 | 24 | 26 | 29 | 33 | 41 | 47 | 55 | 64 |

Tensile strength at 5% strain≥(kN/m) | 23 | 27 | 40 | 45 | 50 | 55 | 65 | 81 | 93 | 110 | 127 |

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: How do geogrids help in reducing carbon footprint in construction projects?

- Geogrids help reduce carbon footprint in construction projects by enabling the use of locally available materials instead of importing heavy construction materials, which reduces transportation emissions. Additionally, geogrids enhance the stability and load-bearing capacity of soil, reducing the need for extensive excavation and the use of concrete and steel, which are carbon-intensive materials. Moreover, geogrids can extend the lifespan of roads and structures, reducing the frequency of repairs and reconstruction, thereby minimizing the carbon emissions associated with construction activities.

- Q: Are geogrids effective in preventing soil creep?

- Yes, geogrids are effective in preventing soil creep. Geogrids are geosynthetic materials that are installed within the soil to provide reinforcement and increased stability. They help to distribute the load and enhance the frictional resistance within the soil, thereby reducing the likelihood of soil creep.

- Q: Peel force mainly in the size of raw materials

- The tensile strength of the welded joints!

- Q: Can geogrids be used in reinforcement of soil-lime mixtures?

- Yes, geogrids can be used in the reinforcement of soil-lime mixtures. Geogrids are commonly used to enhance the engineering properties of soil and improve its stability. When incorporated into soil-lime mixtures, geogrids can provide additional tensile strength and help distribute load more evenly, resulting in increased reinforcement and improved performance of the mixture.

- Q: Light material, wear resistance, chemical stability, light oxygen aging, acid and alkali resistance, suitable for different soil and desert soil conditions.

- It's a double decker!

- Q: What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures are generally minimal. Geogrids are designed to provide long-lasting reinforcement and stability to structures, reducing the need for frequent maintenance. However, periodic inspections should be conducted to ensure the integrity of the geogrid and identify any potential damages or signs of degradation. In some cases, routine cleaning and removal of debris may be necessary to prevent clogging or obstruction of the geogrid. Additionally, if any issues or damages are detected, prompt repair or replacement of the geogrid may be required to maintain the structural integrity and performance of the reinforced structure.

- Q: How do geogrids reduce settlement in embankments?

- Geogrids reduce settlement in embankments by providing reinforcement and improving stability. They distribute loads more evenly across the soil, preventing excessive consolidation and settlement. Moreover, the geogrids also enhance the bearing capacity of the embankment, preventing soil failure and reducing settlement further.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering applications, including pipeline projects, to enhance the stability and load-bearing capacity of soil. By providing tensile strength to the soil, geogrids can help prevent soil movement, improve soil confinement, and increase the overall performance and longevity of the pipeline.

- Q: How do geogrids improve the stability of mechanically stabilized earth walls?

- Geogrids improve the stability of mechanically stabilized earth walls by enhancing the soil's tensile strength and preventing lateral movement. They act as a reinforcement, distributing the applied loads more evenly throughout the structure and reducing the potential for wall failure. Additionally, geogrids increase the frictional resistance between the soil and the wall, effectively increasing the overall stability and performance of the structure.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Biaxial Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords